Heat dissipation structure for cavity filter

A cavity filter and heat dissipation structure technology, which is applied in waveguide devices, electrical equipment components, cooling/ventilation/heating transformation, etc., can solve the problem that the filter cannot meet the circuit structure, etc., to help heat dissipation and increase heat dissipation area, the effect of enhancing the heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

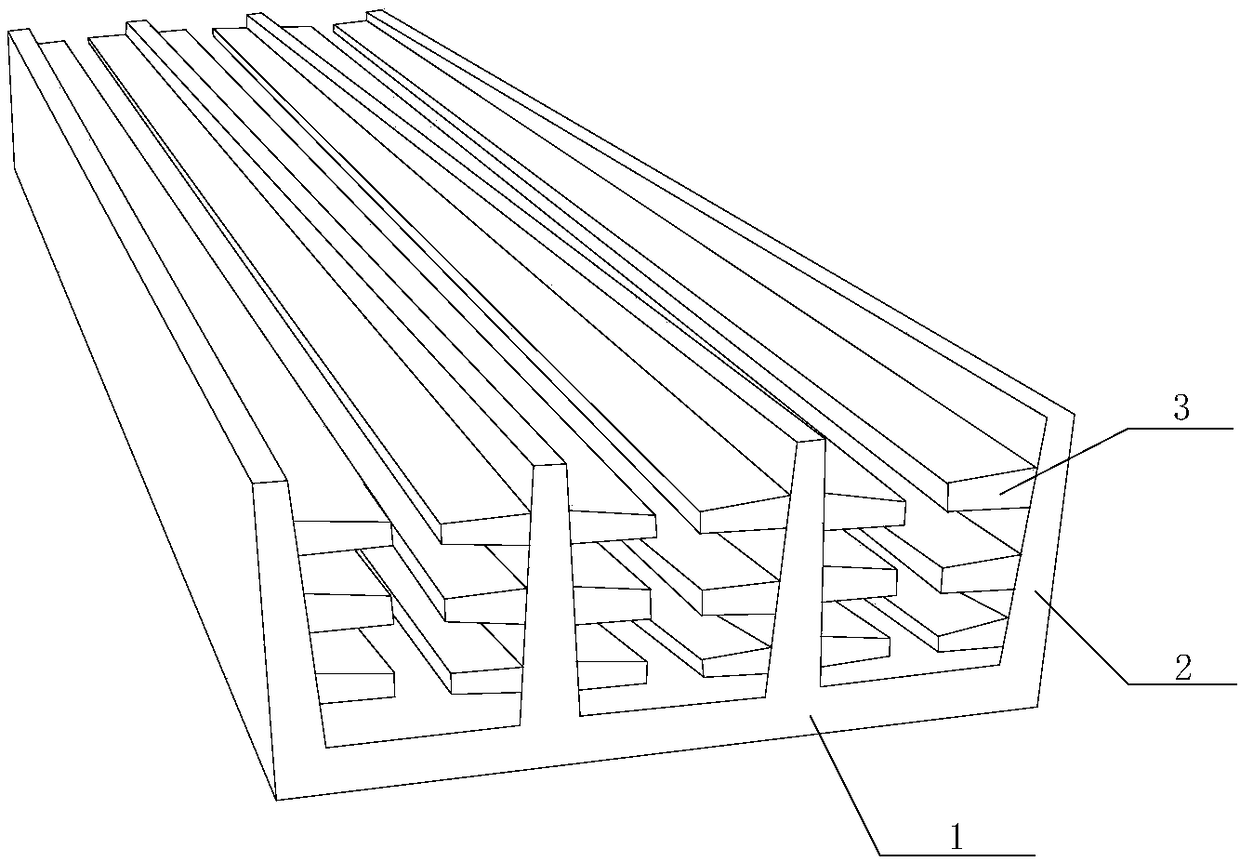

[0019] Such as figure 1 As shown, a heat dissipation structure for a cavity filter of the present invention includes a housing 1, heat sinks 2 evenly distributed on the outer surface of the housing 1, and auxiliary heat sinks 3 located on both sides of the heat sink 2, A plurality of auxiliary heat sinks 3 are evenly distributed on both sides of the heat sink 2. A heat sink 2 and a plurality of auxiliary heat sinks 3 on the heat sink form a heat dissipation unit. There is a gap between the heat dissipation units, and the gap distance is 0.5cm to 1cm. , the heat sink 2 and the auxiliary heat sink 3 are made of aluminum. During implementation, the height of the heat sink can be adjusted as required to enhance its heat dissipation performance. After increasing the height of the heat sink, a plurality of auxiliary heat sinks are added on both sides to increase the heat dissipation area and enhance its heat dissipation performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com