Self-adaptive flask brush head mechanism, flask brush and flask cleaning device

A cleaning equipment and self-adaptive technology, which is applied in the direction of brushes, applications, brush bodies, etc., can solve problems such as inability to wipe brushes, waste of labor, poor effect, etc., and achieve the effect of improving cleaning effect, solving cleaning problems, and being convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

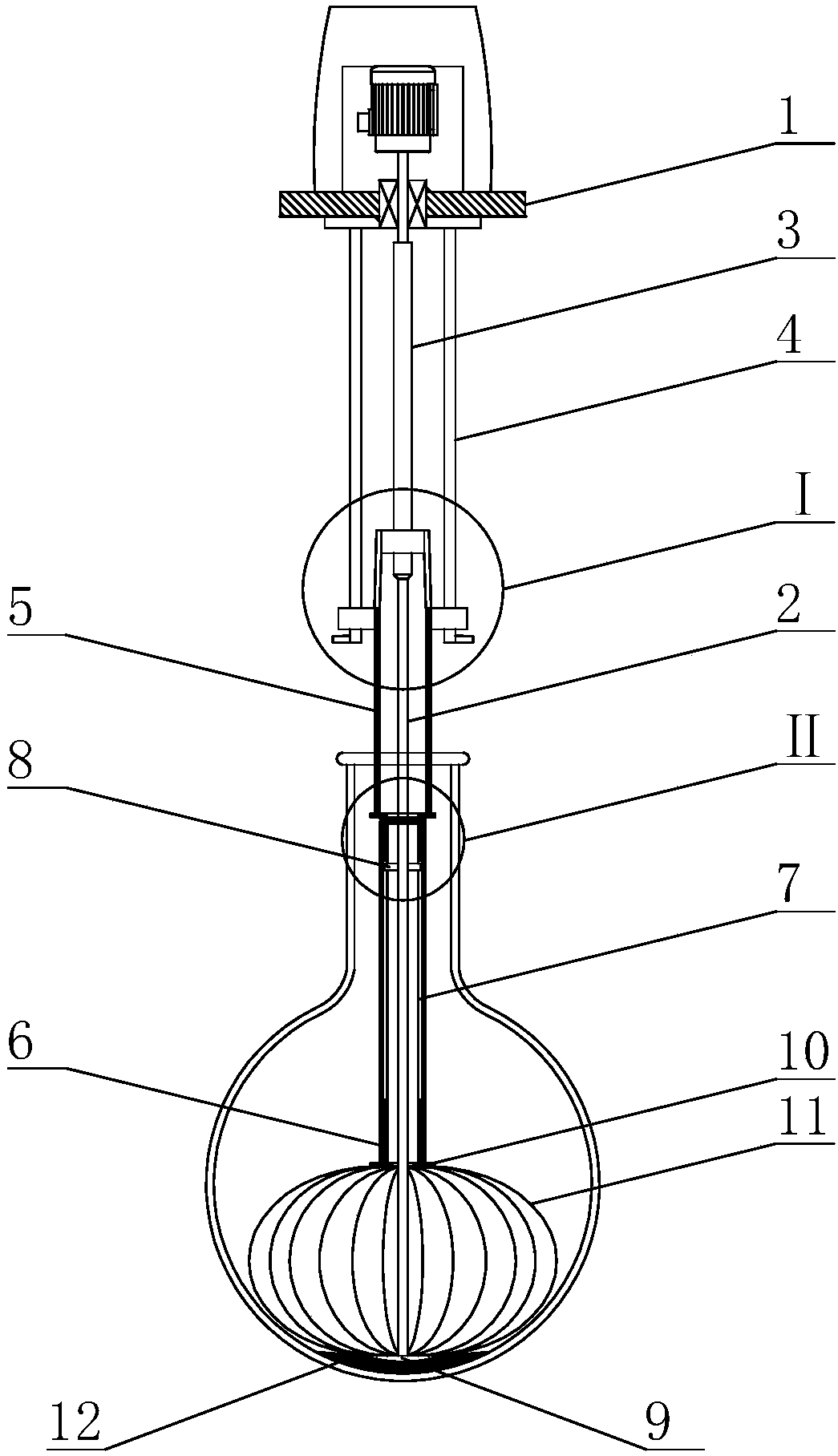

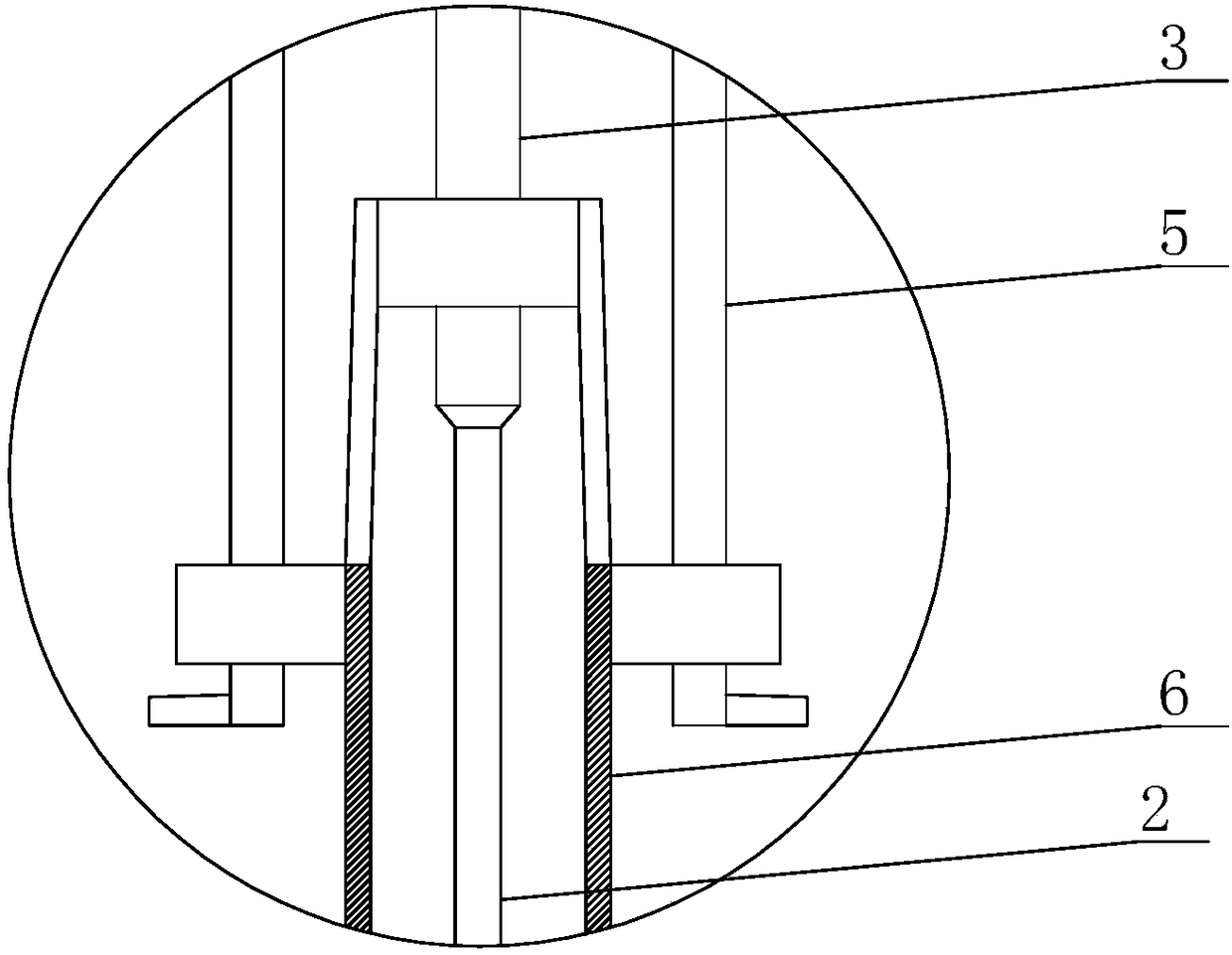

[0040] Embodiment 1: Self-adaptive flask brush head mechanism, the main structure includes a mounting base 1, a central shaft 2 is installed in the center of the mounting base 1, and a control motor is fixed on the mounting base 1. The top of shaft 2 is connected with the control motor. The upper part of the central axis 2 is provided with a first lead screw 3, the first lead screw 3 is provided with a first screw nut matched with it, and a guide rail frame 4 is also fixed on the base along the direction of the central axis 2, The bottom end of the rail frame 4 is provided with a nozzle 14, and a hose 15 for water supply is connected to the nozzle 14. The guide rail frame 4 is provided with a lifting frame 5 sliding up and down along it, the top of the lifting frame 5 is fixedly connected with the first screw nut, and the bottom end of the lifting frame 5 is provided with a control tube 6, and the lifting frame 5 The bottom end of 5 is connected with the top of the control tu...

Embodiment 2

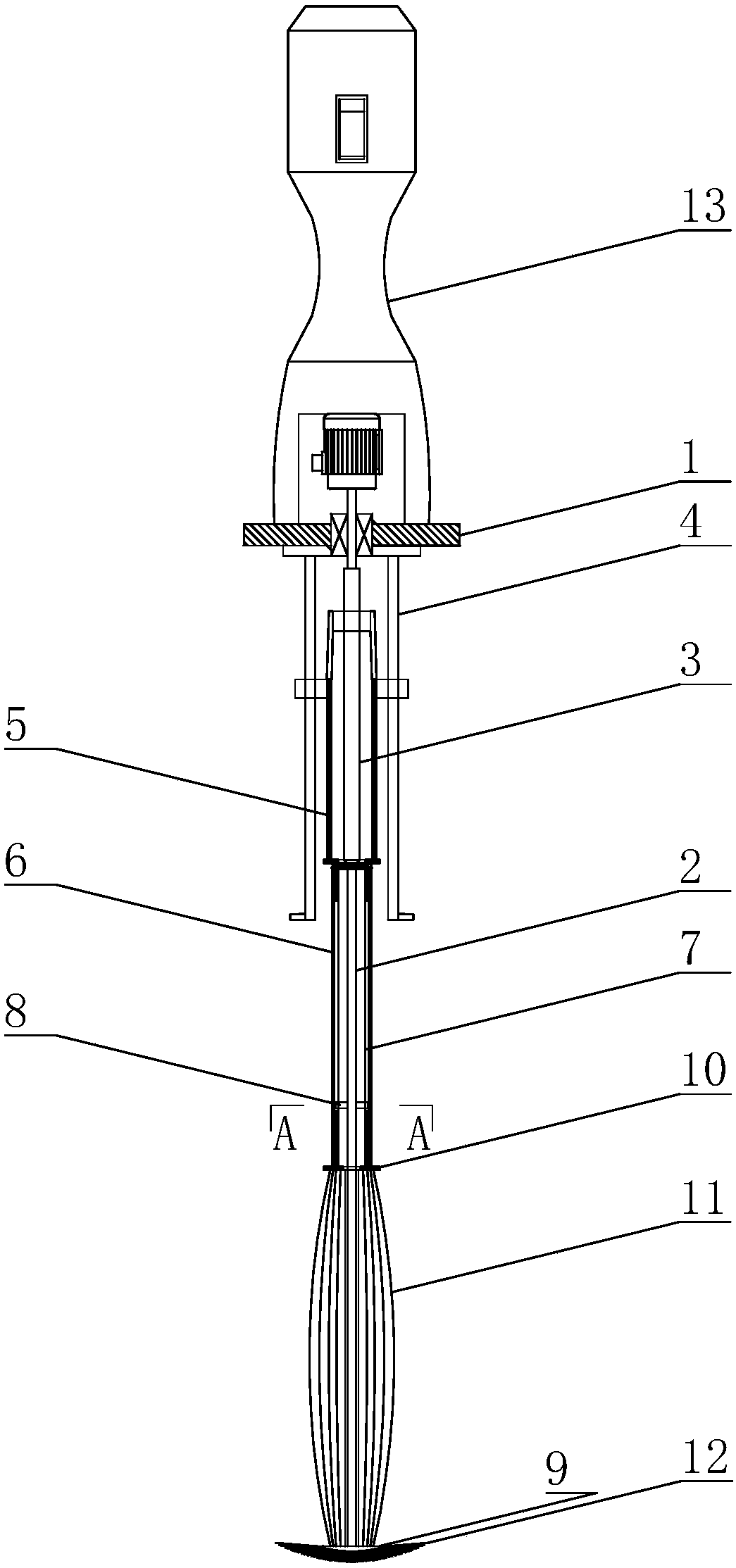

[0041] Embodiment 2: a flask brush, the main structure includes a handle 13, the handle 13 is provided with an installation cavity and a battery box, the battery box is provided with a rechargeable battery, and the installation cavity is provided with a control motor and a controller, so The surface of the handle 13 is provided with a control button and an indicator light that are electrically connected to the controller, and the front end of the handle 13 away from the operator is provided with a mounting base 1, and the center of the mounting base 1 is installed with a central shaft connected to it in rotation. 2. The upper part of the central axis 2 is provided with a first lead screw 3, and the first lead screw 3 is provided with a first screw nut matched with it, and a rail frame is also fixed on the base along the direction of the central axis 2 4. The guide rail frame 4 is provided with a lifting frame 5 that slides up and down along it, the top of the lifting frame 5 is...

Embodiment 3

[0042] Embodiment 3: flask cleaning equipment, the main structure includes a fixed seat 18 and a frame 19, the top of the frame 19 is provided with a lifting mechanism, the bottom of the frame 19 is fixedly connected with the fixed seat 18, and the lifting mechanism includes Vertically arranged slide rail 16 and the second leading screw 17, described second leading screw 17 is provided with the second screw nut that matches with it, and described slide rail 16 is provided with the slide block that cooperates with it, and described slide The block and the second nut are all fixed on the installation base 1, and the middle shaft 2 connected with it is installed in the center on the installation base 1, and the control motor is fixed on the said installation base 1, and the top of the middle shaft 2 Connect with the control motor. The upper part of the central axis 2 is provided with a first lead screw 3, the first lead screw 3 is provided with a first screw nut matched with it, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com