Top cover assembly of dishwasher

A top cover and component technology, which is applied to the parts of the washing machine/rinsing and washing machine of the tableware, the washing machine/rinsing machine of the tableware, cleaning equipment, etc., can solve the problems of sealing failure, falling off, and loosening of the sealing strip, so as not to loosen , low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

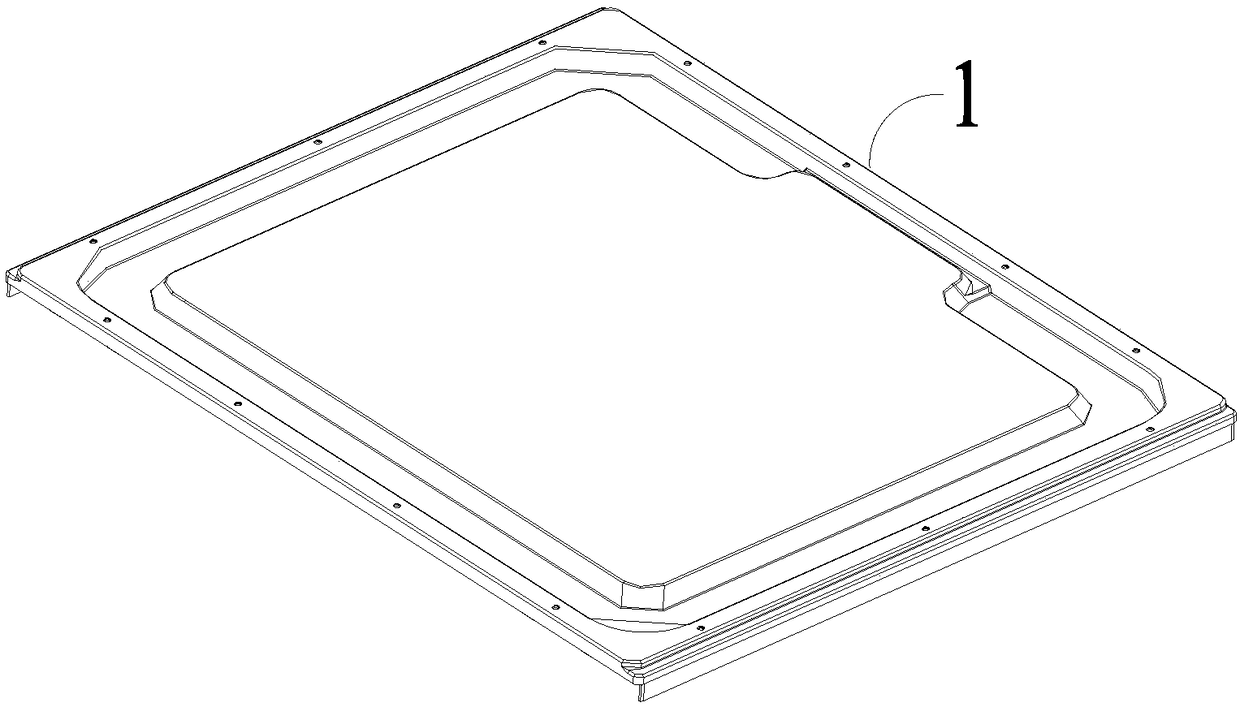

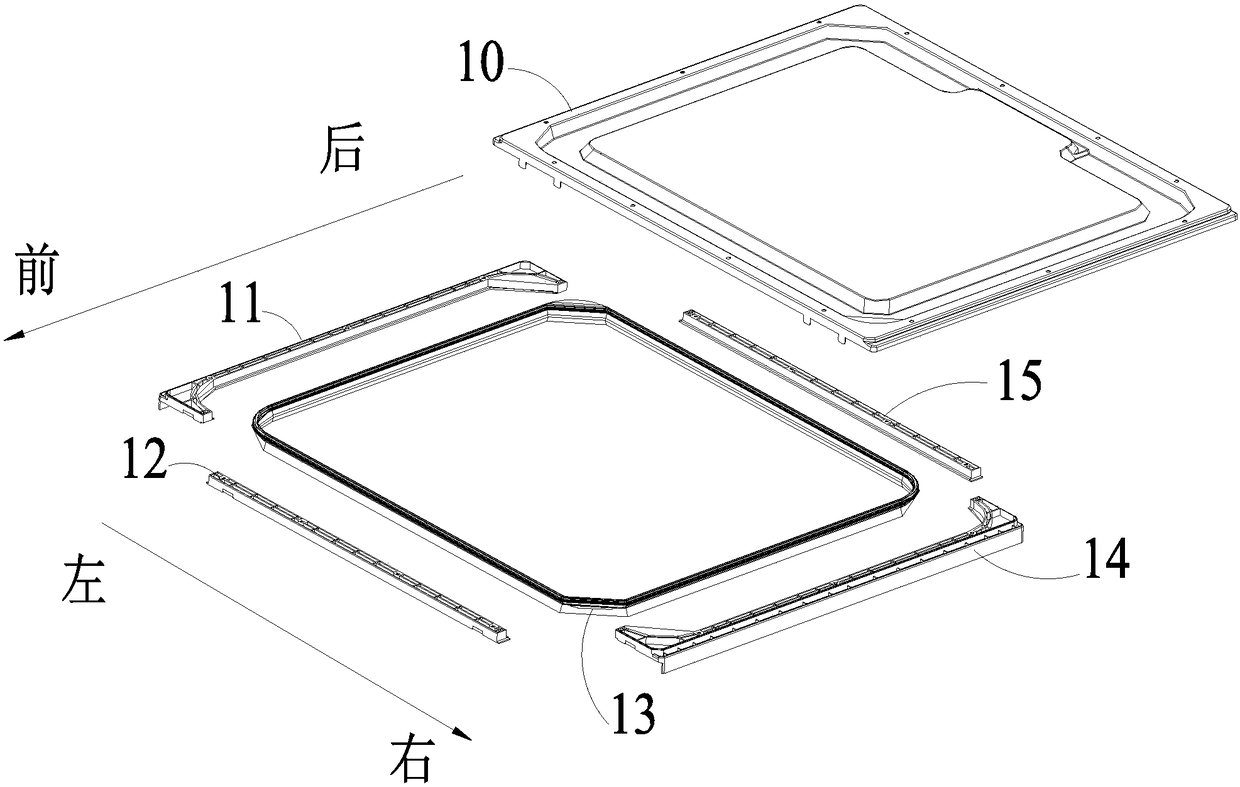

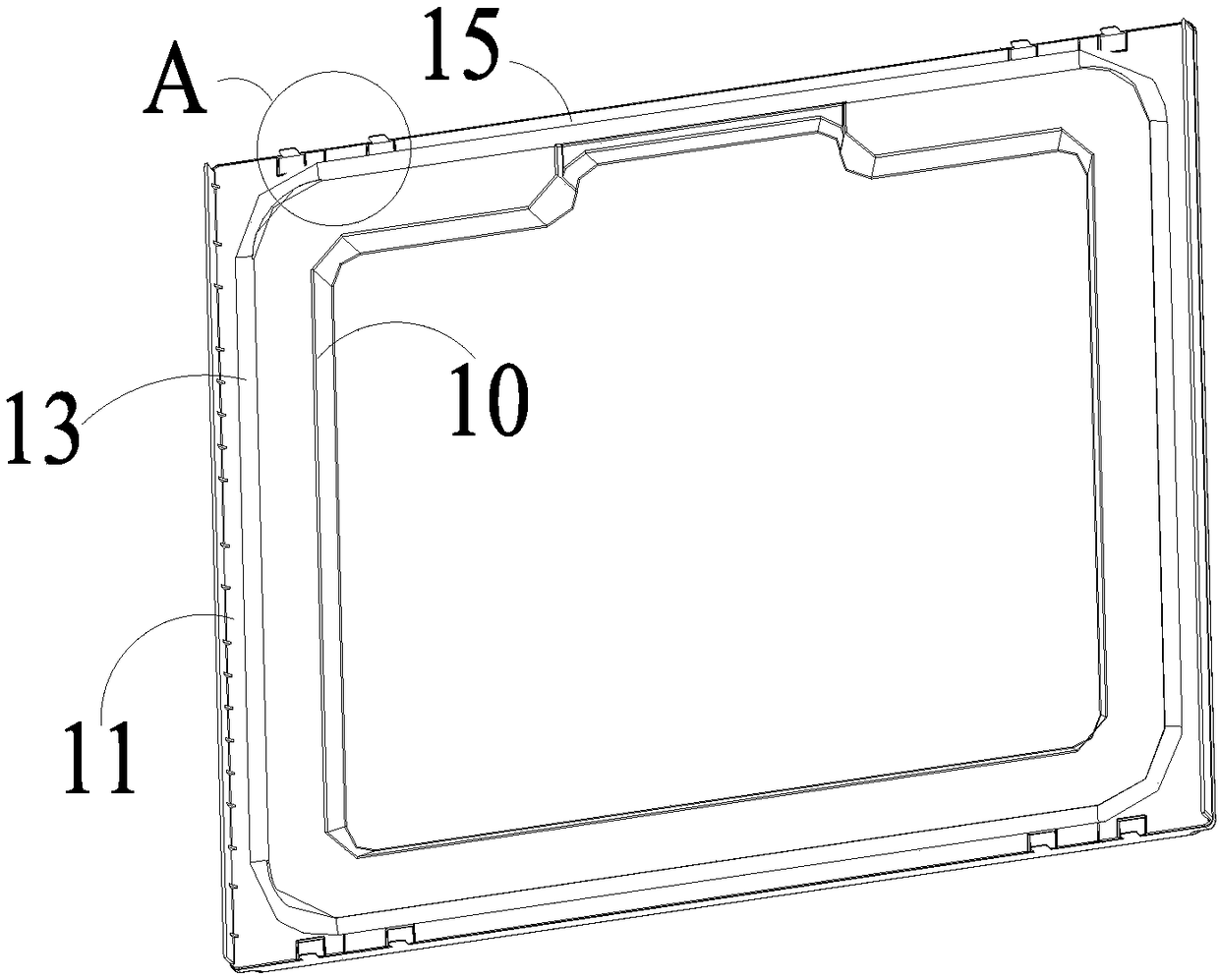

[0034] see figure 1 and 2 , The top cover assembly 1 of the dishwasher includes a top cover 10 , a sealing strip 13 and sealing pressure plates 11 , 12 , 14 and 15 . The sealing pressing plates 11 , 12 , 14 and 15 jointly fasten the sealing strip 13 on the top cover 10 .

[0035] Now the specific structure of each component of the top cover assembly 1 will be described, and the structure of the sealing platen will be described first. In this embodiment, the sealing press plate is divided into two types according to the difference in structure, that is, the first sealing pressing plate and the second sealing pressing plate. The first sealing pressing plate is roughly linear, and the front sealing pressing plate 12 and the rear sealing pressing plate 15 belong to The first type of sealing platen. see Figure 13 and 14 , the rear sealing platen 15 is taken as an example, the rear sealing platen 15 includes a linear main body 152, a side edge 151 extends from the main body 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com