Novel cloth cutting device for warp knitting machine

A warp knitting machine and cloth cutting technology, which is applied in the direction of grinding drive device, grinding/polishing safety device, grinding machine tool parts, etc., can solve the problems of low work efficiency, waste of time, complicated operation, etc., to ensure safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

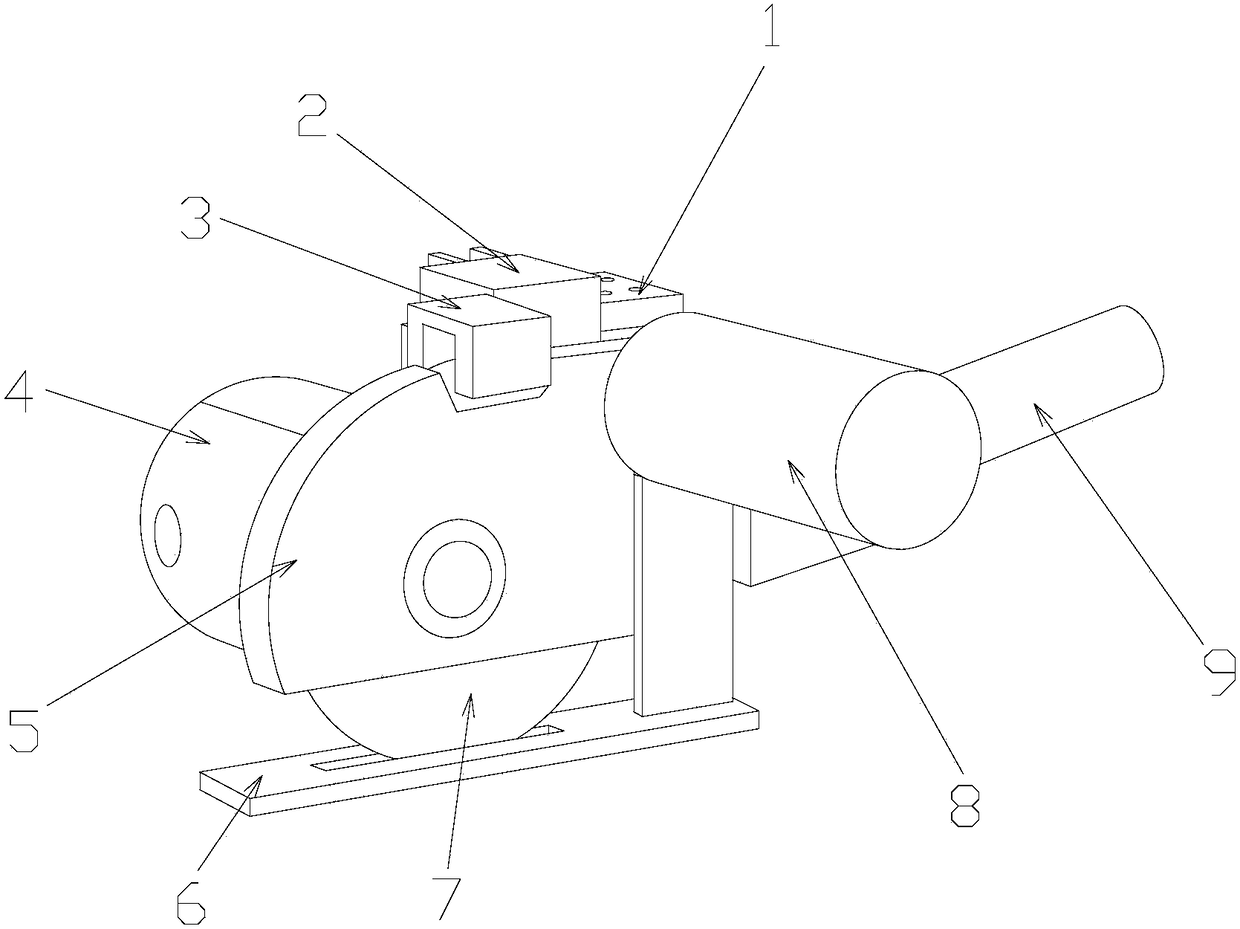

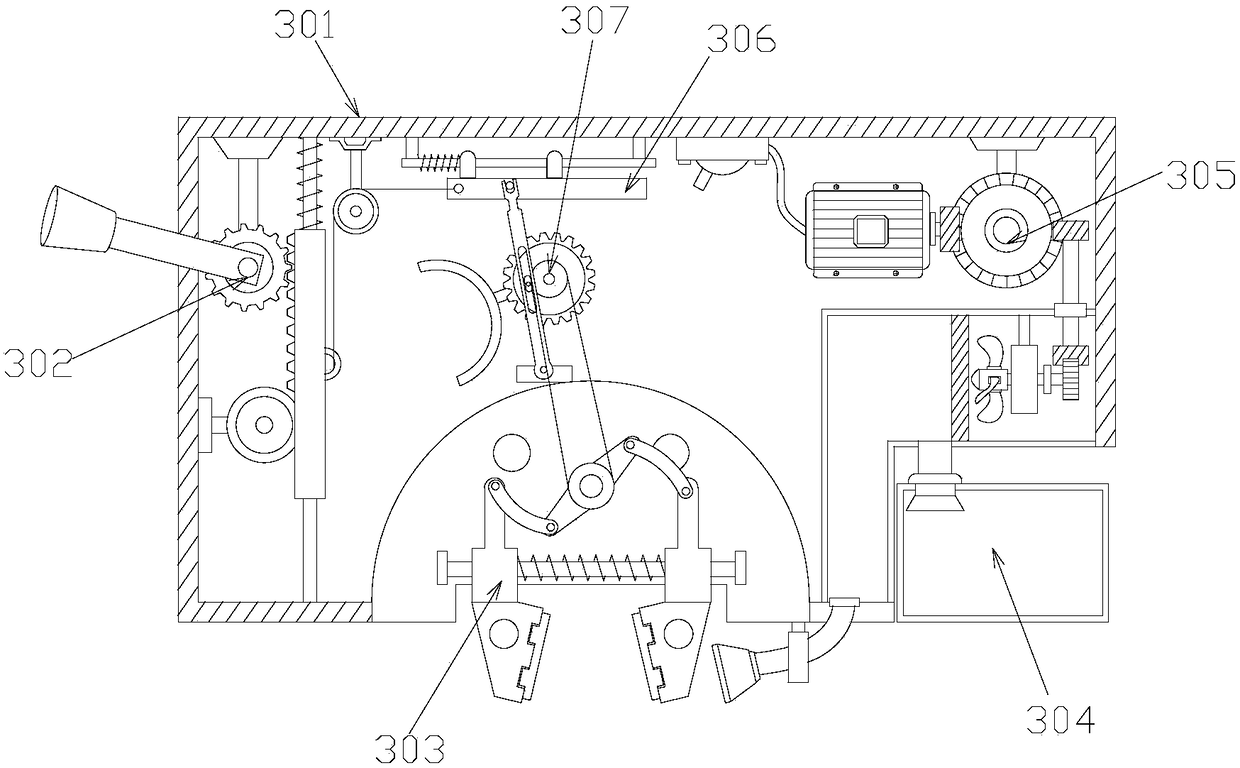

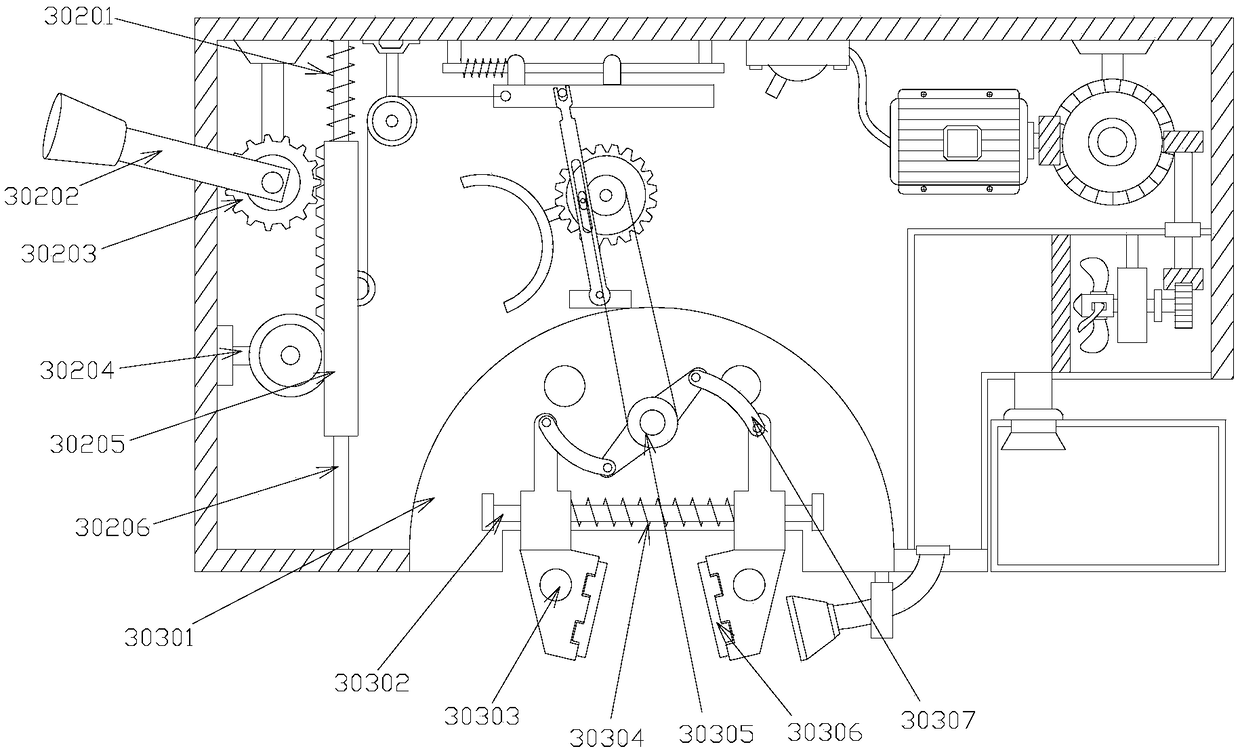

[0021] like Figure 1-Figure 5As shown, the present invention provides a novel warp knitting machine cloth cutting device, its structure includes a device controller 1, a power socket 2, a sharpening device 3, a blade drive motor 4, a blade protective cover 5, a cloth cutting device guide rail 6, Cloth cutting blade 7, balance iron insulation protector 8, anti-slip handle 9, the blade protection cover 5 bolts are fixed above the guide rail 6 of the cloth cutting device, the anti-slip handle 9 is installed on the right side of the blade protection cover 5, and the balance iron The insulating protector 8 is positioned at the front upper right corner of the blade guard 5 and is perpendicular to the blade guard 5. The power socket 2 is positioned at the upper right corner behind the blade guard 5. The device controller 1 is installed on the right side of the power socket 2 and is connected to the blade guard 5. The power socket 2 is electrically connected, the blade drive motor 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com