Novel connection structure for oil well pipes and couplings

A connection structure, oil well pipe technology, applied in the field of machinery, can solve problems such as excessive wear, decreased sealing performance of threaded connections, bonding and occlusal strength, etc., and achieve the effects of enhancing overall safety, reliable sealing connection, and strong sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

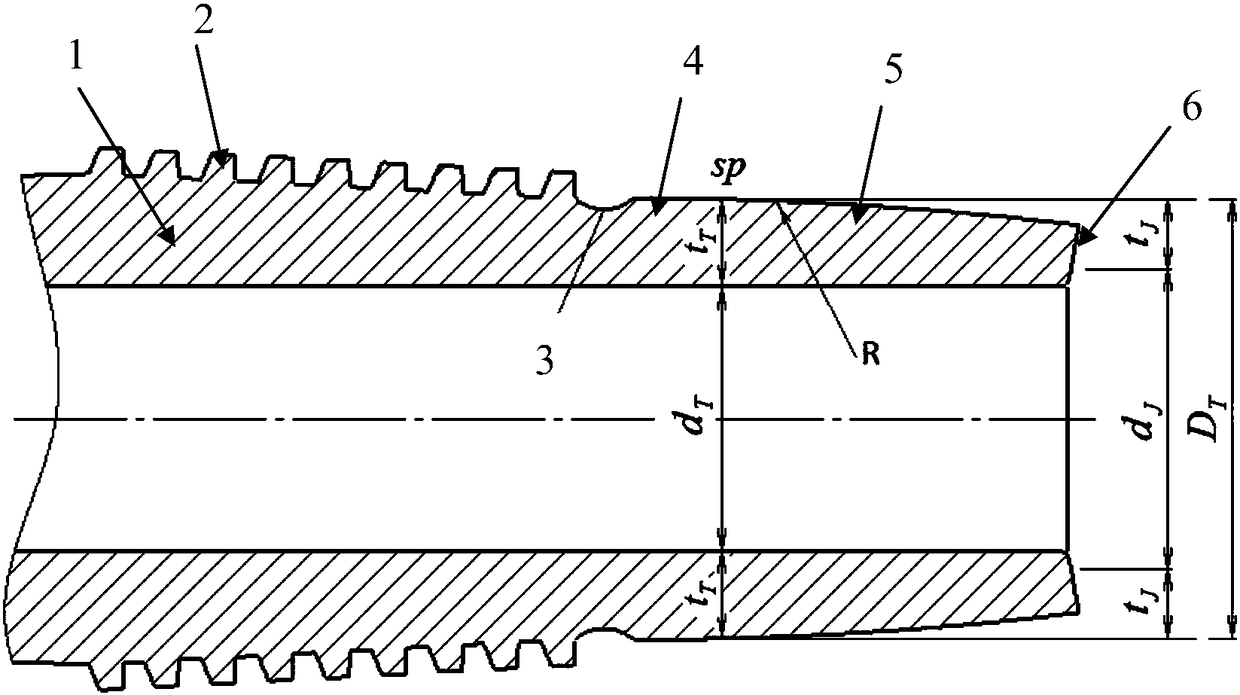

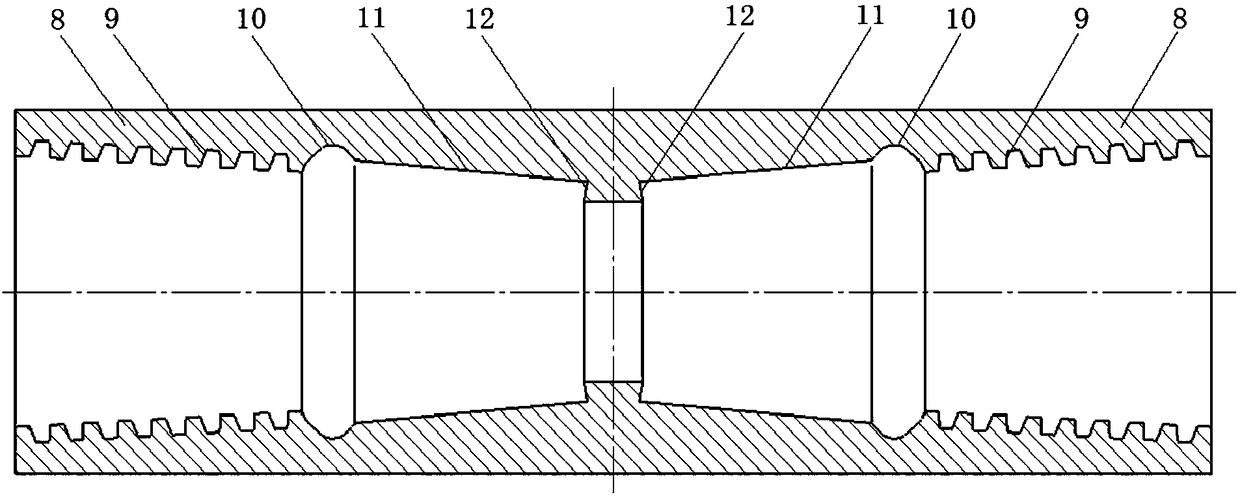

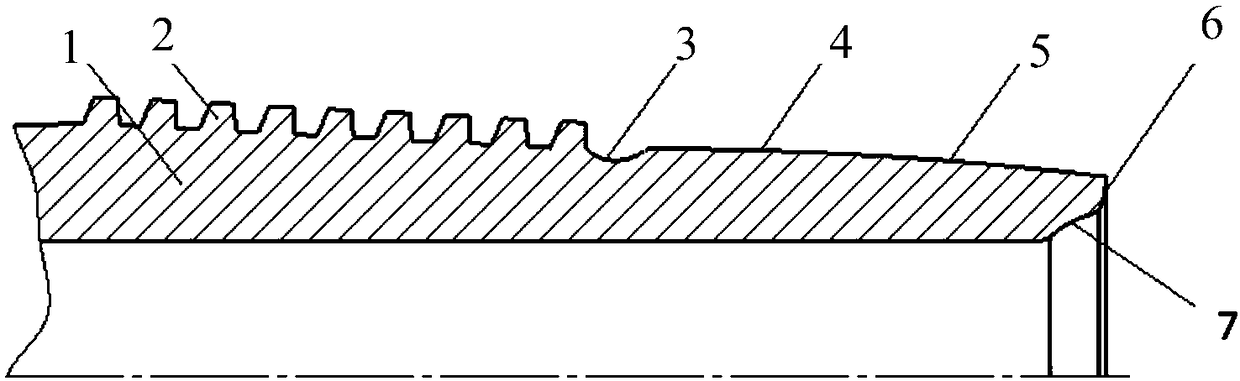

[0041] see Figure 1 to Figure 4 , the present invention provides a novel connection structure between an oil well pipe and a coupling, which includes a plurality of oil well pipes, and the ends of any two adjacent oil well pipes are connected by a coupling;

[0042] The end of each oil well pipe includes a hollow oil well pipe end body 1, the outer wall of the rear end of the oil well pipe end body 1 is distributed with multiple turns of external threads 2, and the front end of the oil well pipe end body 1 has guide column 5;

[0043] Each of the couplings includes a hollow coupling body 8, and the inner walls of the front ends of the left and right sides of the coupling body 8 are respectively symmetrically distributed with multiple turns...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com