Liquid storage container and manufacturing method thereof

A technology for a liquid storage container and a container body, which is applied in the field of liquid storage containers and their manufacturing, can solve the problems of unreliable sealing and long production cycle, and achieve the effects of shortening production cycle, improving assembly efficiency, and reliable pressing and sealing connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

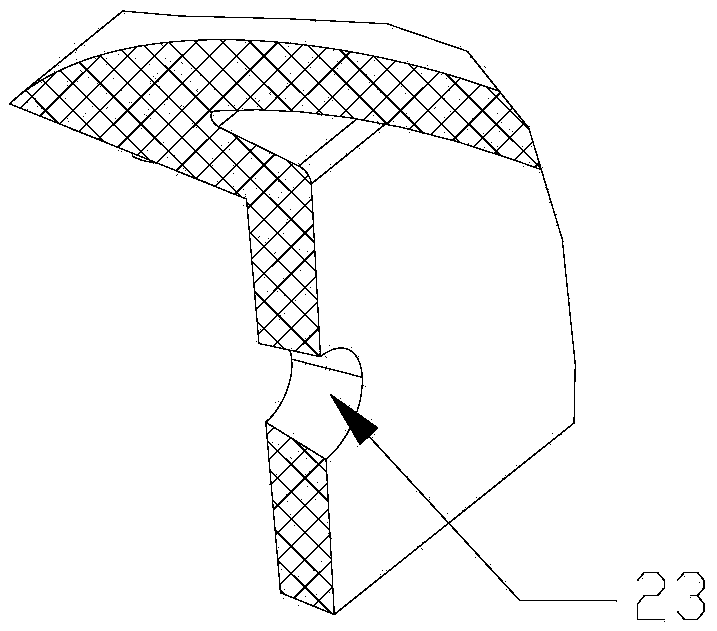

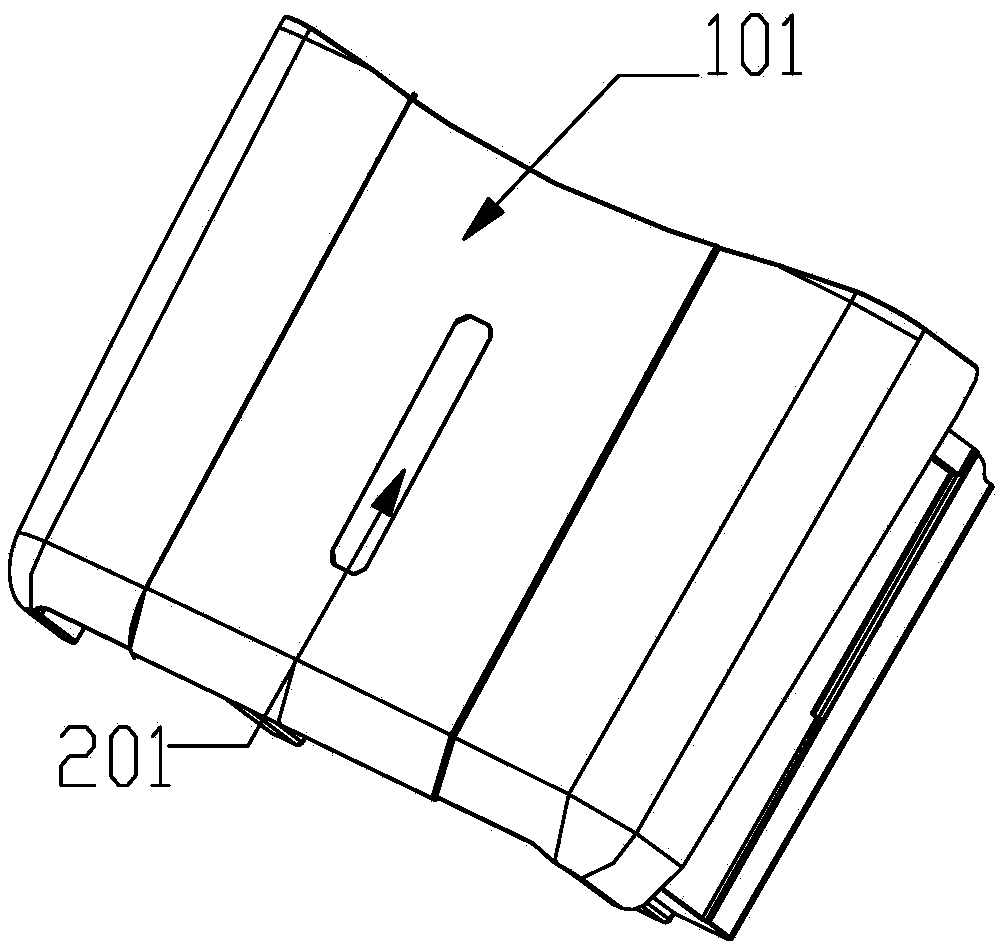

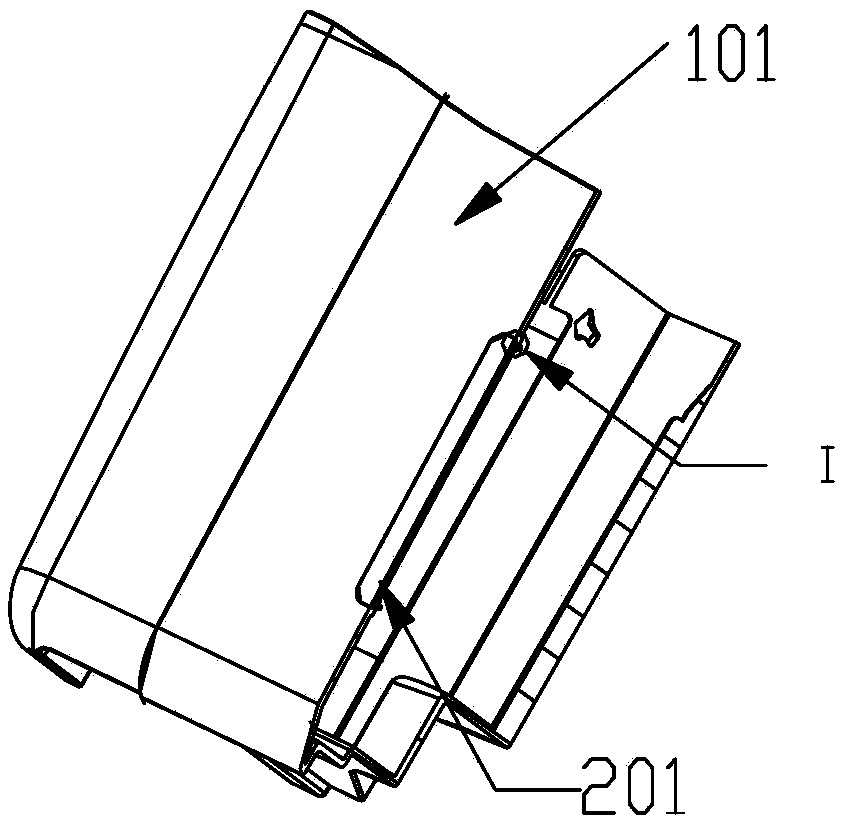

[0038] see Figure 4-Figure 8b , to describe the liquid storage container of the present invention, the liquid storage container of the present invention includes: a container body 1 and a window 2 assembled together. The viewing window 2, and the first locking member (in this embodiment, a reaming hole 23) and the first sealing member (in this embodiment, a groove 21) formed on the viewing window 2 form a first integral part, in other words, The viewing window 2, the first locking member and the first sealing member are molded and injection-molded together as an integral part through one injection molding; the container body 1 and the second locking member (in this embodiment, a post) formed on the container body 1 Body 23'), the second sealing member (protrusion 21' in this embodiment) constitute the second integral part, that is, the container body 1, the second locking member, and the second sealing member are formed by one injection molding and injection molded on Anothe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com