Disposable humidification bottle system for medical oxygen inhalator

A humidification bottle and inhaler technology, applied in the field of medical devices, can solve the problems of expensive disinfection equipment, unfavorable environmental protection for patients to use safely, and inconvenient drying and storage of the humidification bottle, so as to avoid post-disinfection treatment procedures and reduce nursing labor. Strength, good effect of oxygen humidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

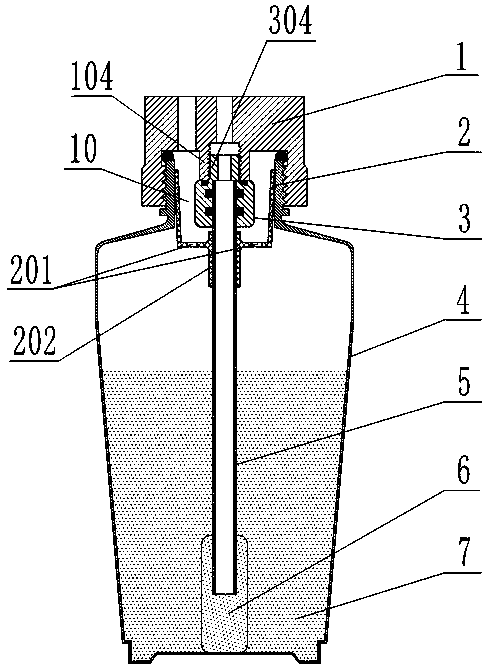

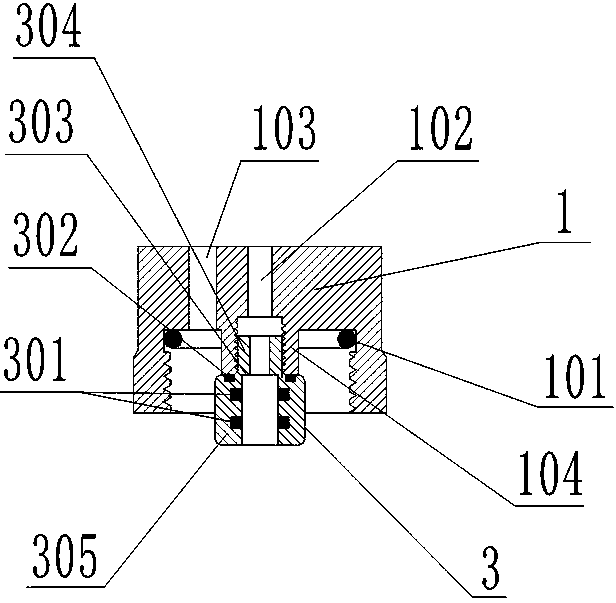

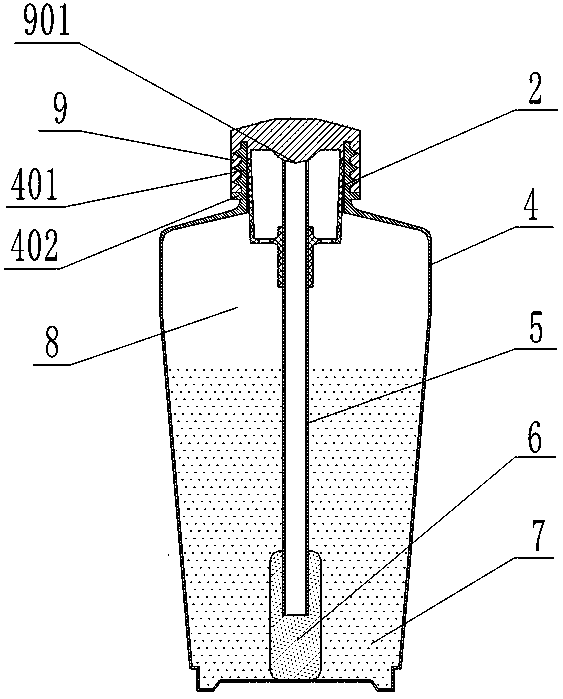

[0044] like Figure 1 ~ Figure 3 As shown, a disposable humidification bottle system for an inhaler, including a humidification bottle 4, a trachea bracket 2, a plug connector 3, a trachea 5, a humidification core 6 and a valve body 1, and the top of the humidification bottle 4 There is a bottleneck 401, and the valve body 1 is tightly connected with the bottleneck 401 (such as figure 1 As shown, the valve body 1 has a threaded sleeve, and the threaded sleeve of the valve body 1 is thread-tightly connected with the bottleneck 401 of the humidification bottle 4; the bottom of the bottleneck 401 has a limit step 402 matching the threaded sleeve of the valve body 1), The middle part of the valve body 1 has a plug-in connection part 104, and the top of the plug-in joint 3 is tightly plugged on the plug-in connection part 104 of the valve body 1. The middle part of the valve body 1 has an air inlet 102, and the middle part of the plug joint 3 has a connection with the air inlet. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com