Hydraulic interlocking control system

A control system and hydraulic technology, applied in the direction of fluid pressure actuation system safety, fluid pressure actuation system components, fluid pressure actuation device, etc., can solve misoperation accidents, cost huge financial resources and manpower, and equipment damage crisis site personnel life safety issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

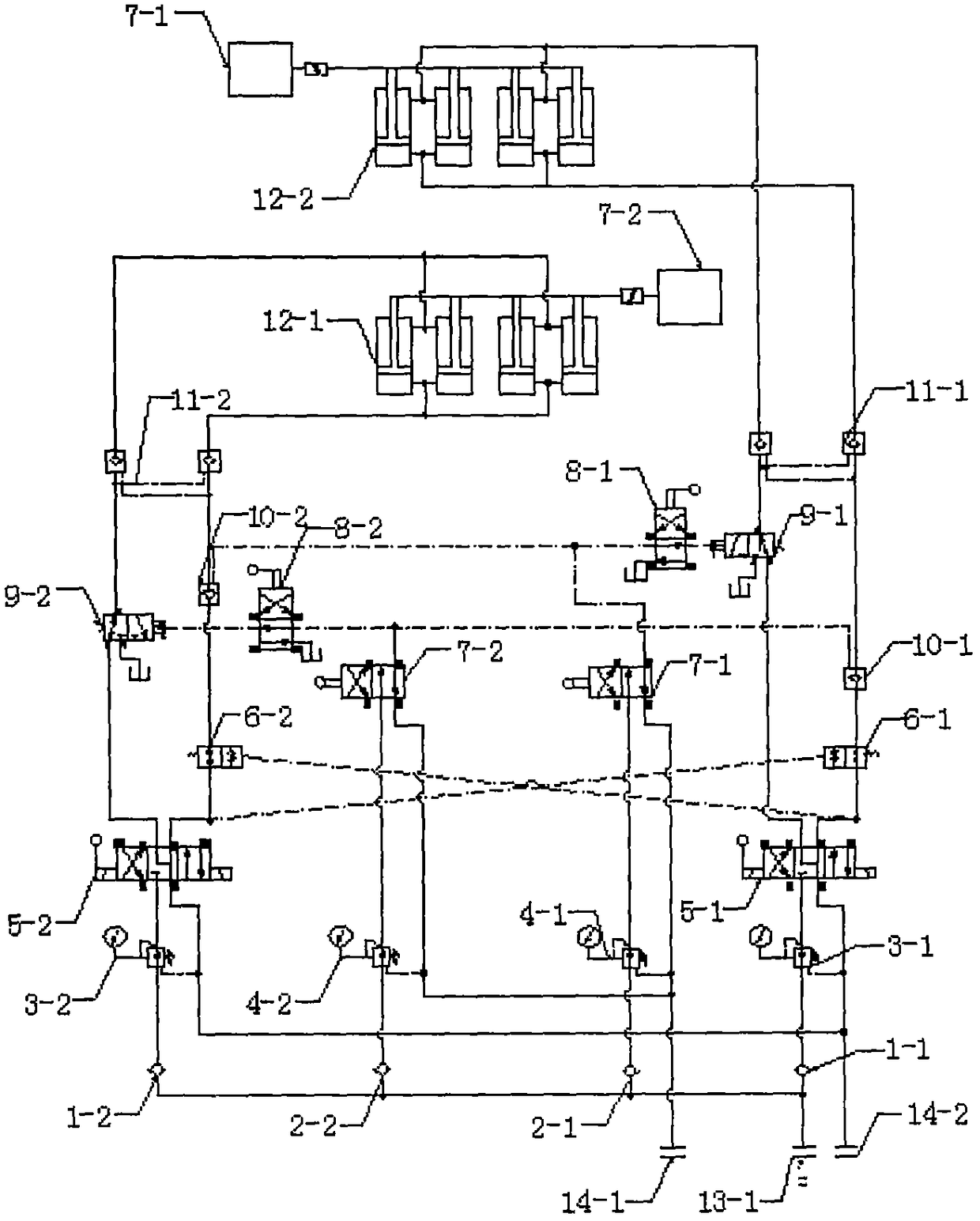

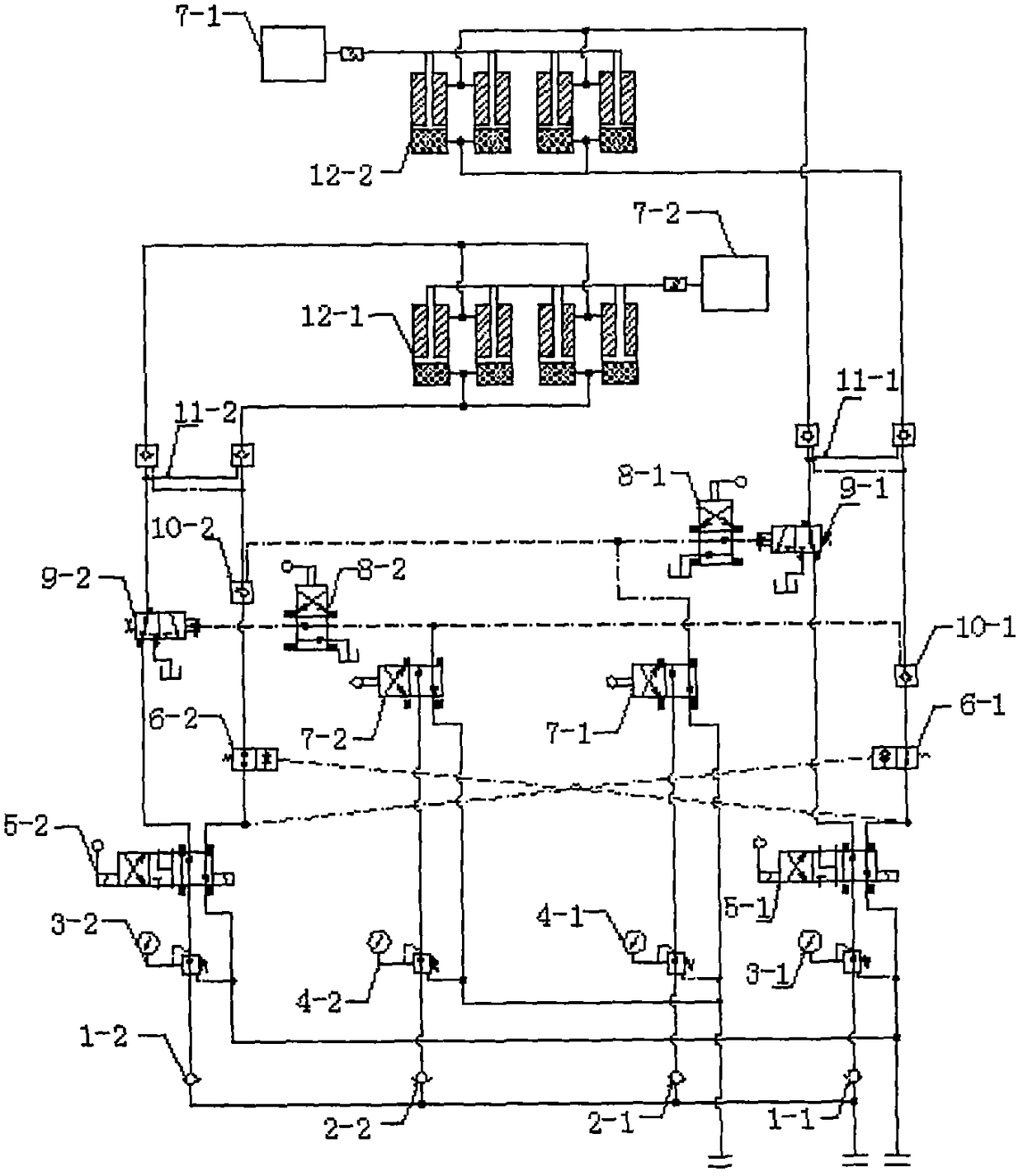

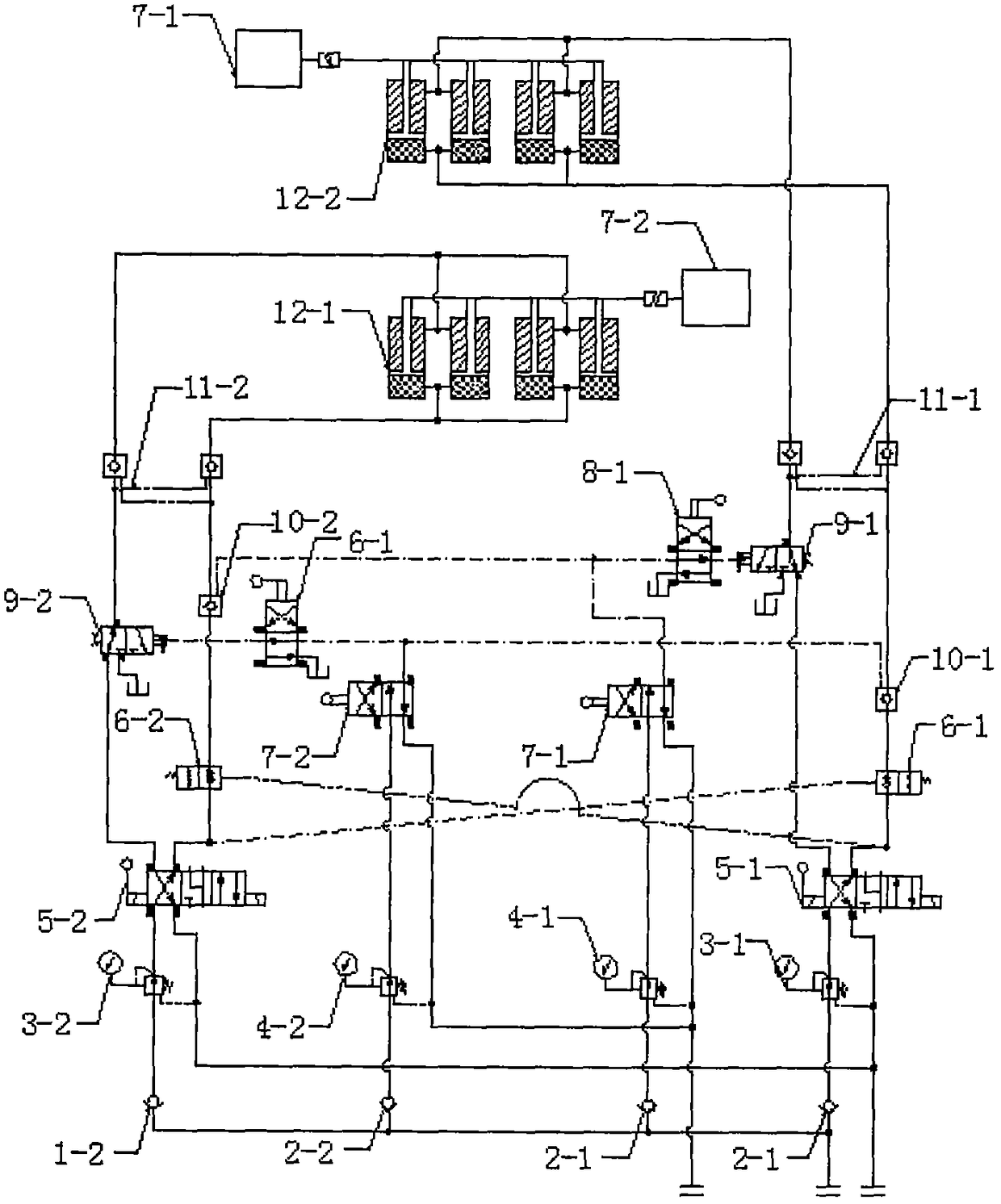

[0015] like Figure 1-3 As shown, the present invention provides a hydraulic interlock control system, including oil cylinder A12-1, oil cylinder B12-2, oil inlet 13-1, oil outlet A14-1 and oil outlet B14-2, oil inlet 13-1 is connected to the oil cylinder A12-1 through the first oil delivery pipe, the oil inlet 13-1 is connected to the oil cylinder B12-2 through the second oil delivery pipe, and the oil outlet B14-2 is connected to the oil cylinder A12-1 through the first oil return pipe. The oil port B14-2 is connected to the oil cylinder B12-2 through the second oil return pipe, and the connection between the first oil delivery pipe and the first oil return pipe is installed with a pressure reducing valve A3-1, a manual valve A5-1 and a hydraulic control check valve C11- 1. The first oil delivery pipe is connected to the second oil return pipe through logic valve C9-1, manual valve C8-1 and hydraulic control check valve B10-2; a pressure reducing valve B3 is installed betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com