A mechanical lifting device and method for releasing high-temperature melt

A high-temperature melting and mechanical lifting technology, applied in the direction of reducing greenhouse gases, climate sustainability, reactors, etc., can solve problems affecting the dynamic stratification behavior of melts, melt pollution, poor reliability, etc., to ensure reliability and avoid The effect of high cost and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

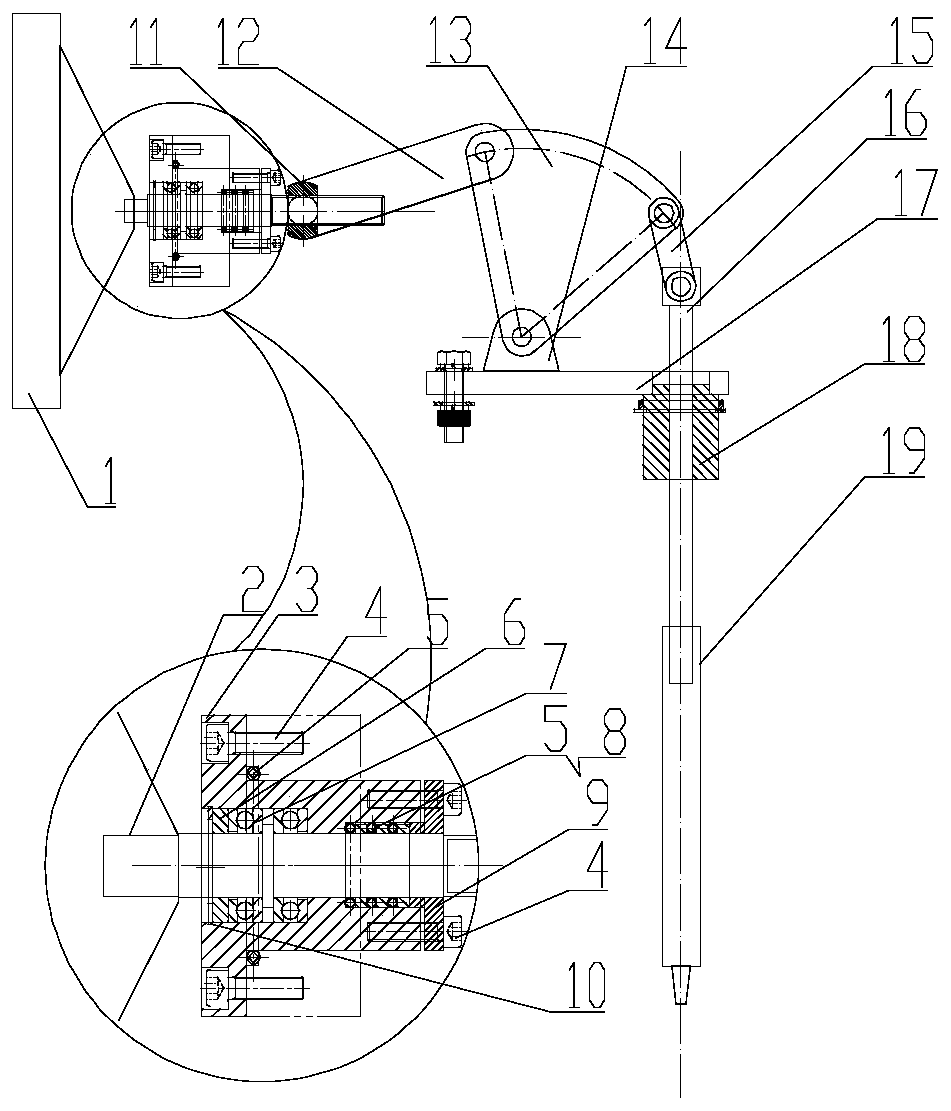

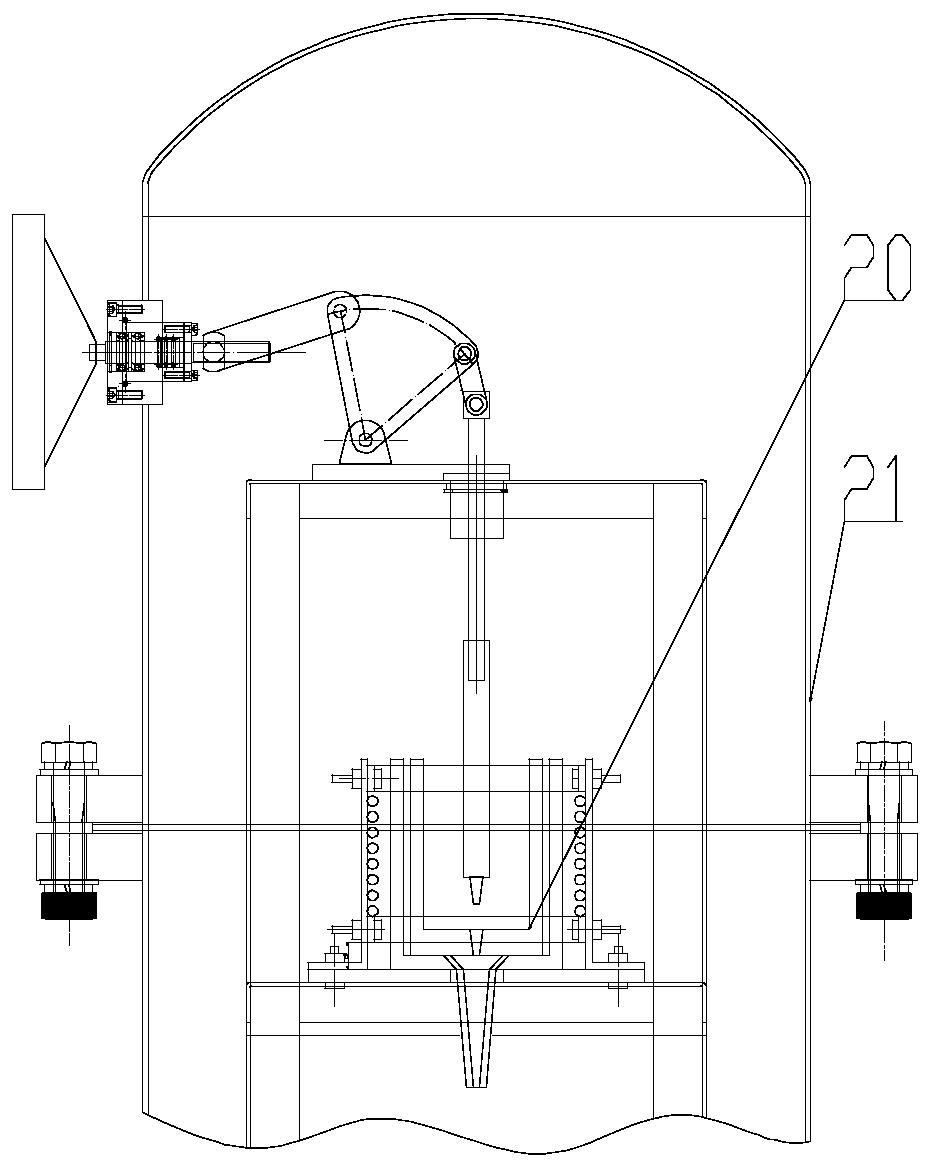

[0032] Such as figure 1 and figure 2 As shown, the present invention is a mechanical lifting device for high-temperature melt release, including a release mechanism, a connection mechanism, a sealing mechanism and a power mechanism arranged on the heating system 20 in the pressure vessel 21; the sealing mechanism is used To ensure the sealing of the lifting device and the pressure vessel, it includes a bearing block 3 connected to the pressure vessel 21, a screw 4 for connecting the pressure vessel 21 and the bearing seat 3 (hexagon socket head cap screws in this embodiment), and a screw located in the pressure v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com