3D printing personalized talus surface replacement prosthesis

A 3D printing and prosthesis technology, applied in 3D printing, prosthesis, additive manufacturing, etc., can solve problems such as prosthesis loosening, long-term prognosis concerns, failure, etc., to reduce the probability of brittle failure, increase connection stability, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

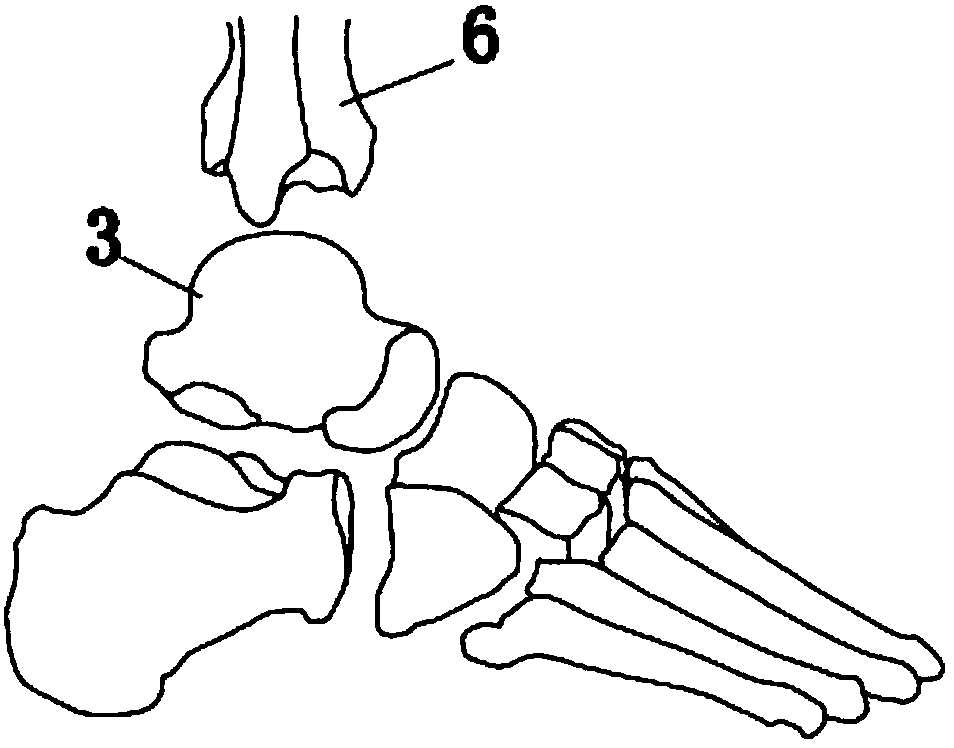

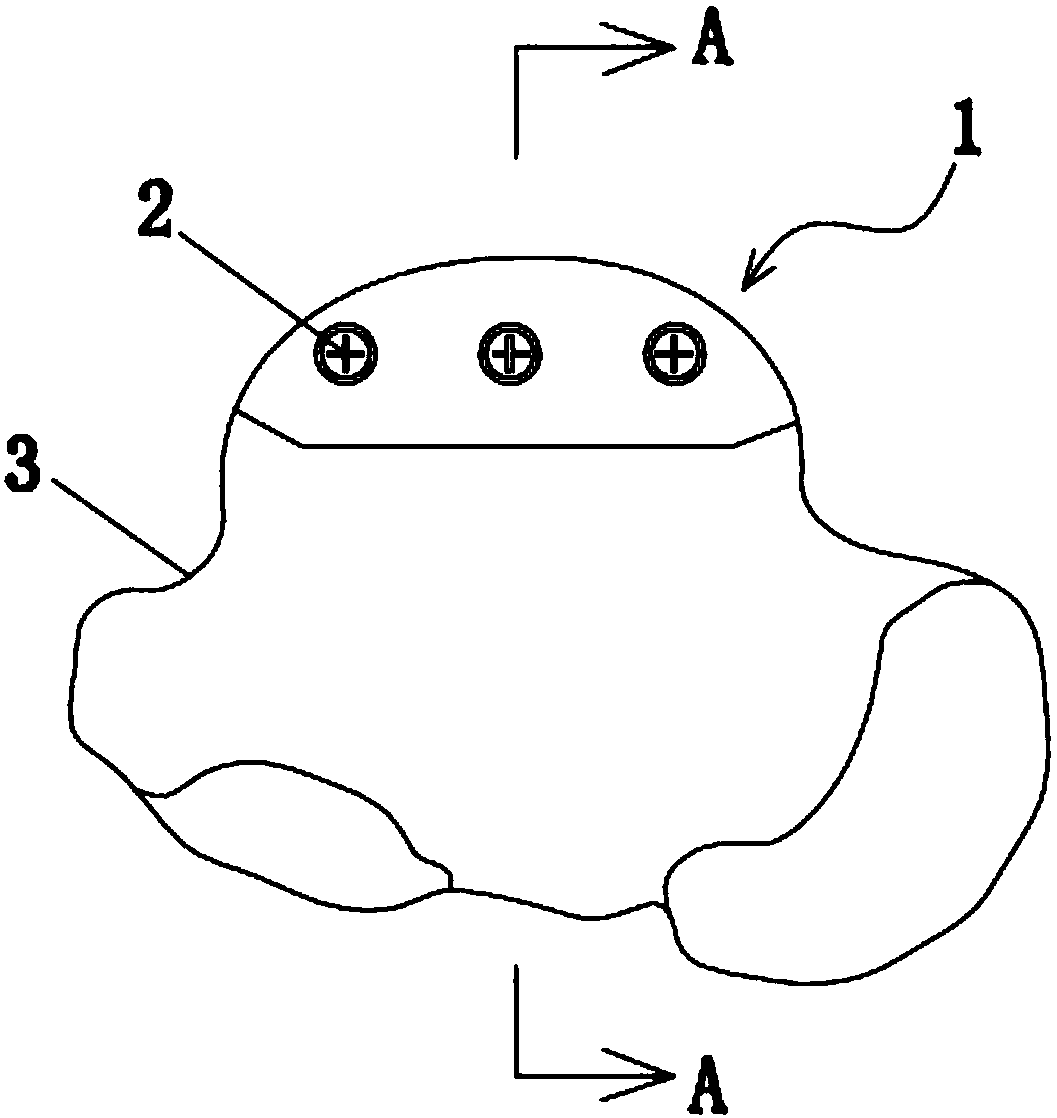

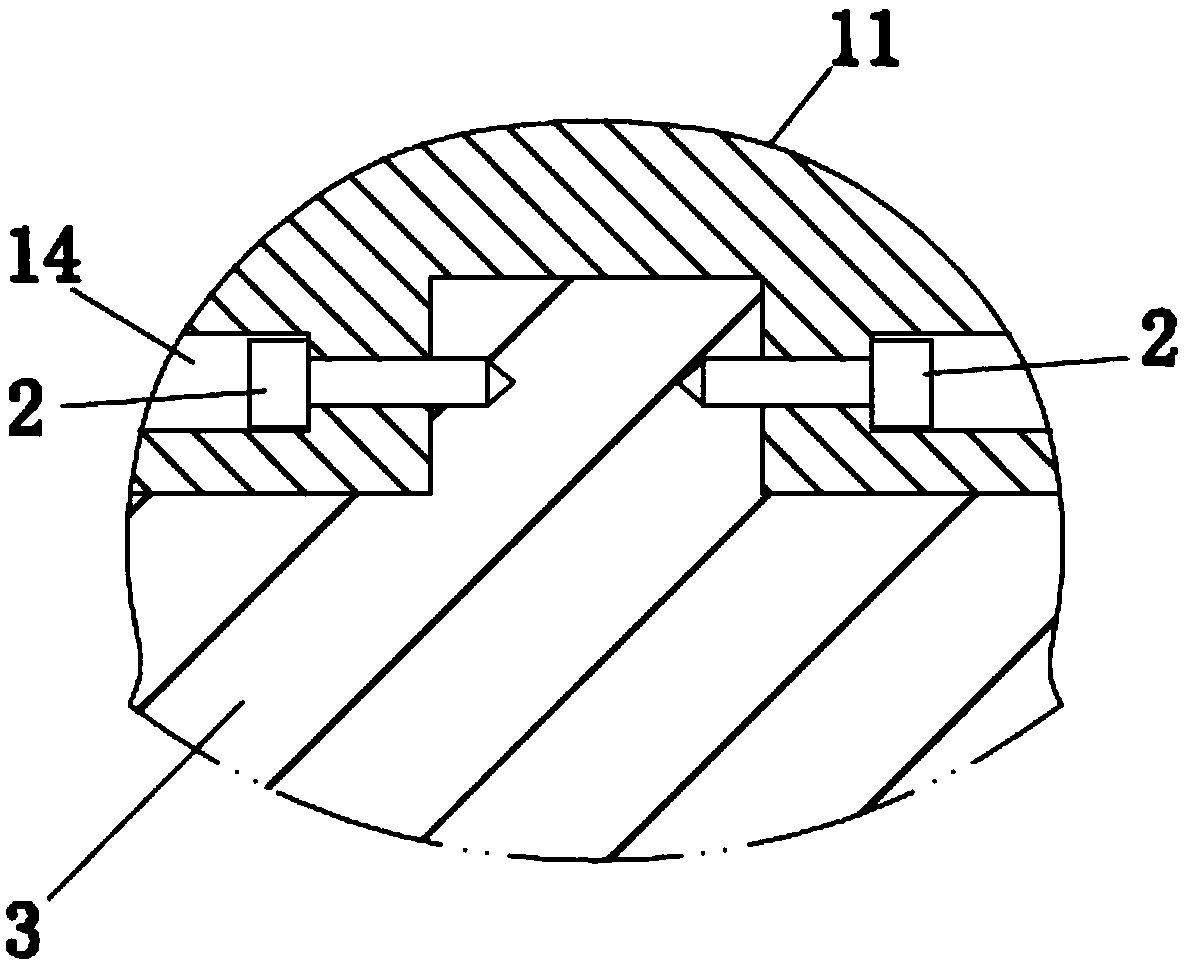

[0035] Specific embodiments of the present invention are as follows Figure 1 to Figure 5 As shown, a 3D printed personalized talus surface replacement prosthesis, including a prosthesis 1 made by 3D printing technology, the prosthesis 1 includes a smooth connecting surface 11 for matching with the lower articular surface of the tibia 6 and a 3. The rough contact surface 12 adapted to the excised part, the prosthesis 1 also includes a body 13 between the smooth connecting surface 11 and the rough contact surface 12, and the rough contact surface 12 is provided with a new growth bone through the talus 3. The prosthesis 1 is provided with connecting pieces for connecting the talus 3 with the prosthesis 1 . The resected part of the talus 3 is in contact with the rough contact surface 12 on the prosthesis 1, and the talus 3 and the prosthesis 1 are fixed to each other through the connector. During the healing stage, the newly grown bone of the resected part of the talus 3 can prot...

Embodiment 2

[0042] like Image 6 and Figure 7 As shown, the difference from Embodiment 1 is that the rough contact surface 12 is flat, and the part of the talus 3 that fits with the rough contact surface 12 is also flat, and the two are in contact with each other. The screw 2 passes through the countersunk hole 14 and is inserted obliquely into the flat surface of the talus 3 in contact with the rough contact surface 12.

Embodiment 3

[0044] like Figure 8 As shown, the difference from Embodiment 1 is that the connecting piece includes matching bolts 4 and nuts 5, the countersunk holes 14 are paired in pairs, and the two countersunk holes 14 in each pair are opposite and identical to each other. The shaft is arranged, the groove 15 is located between each pair of two countersunk holes 14, the bolt head of the bolt 4 and the nut 5 are respectively located in the two pairs of countersunk holes 14, and the screw rod of the bolt 4 passes through the pair of countersunk holes 14. Counterbore 14.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com