Electric conduction hairspring stress-free operating device

An operating device and stress-free technology, applied in the direction of circuits, electrical components, circuit/collector components, etc., can solve problems such as elastic deformation of conductive hairspring, shape change of conductive hairspring, instrument interference torque, etc., and achieve the effect of avoiding internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

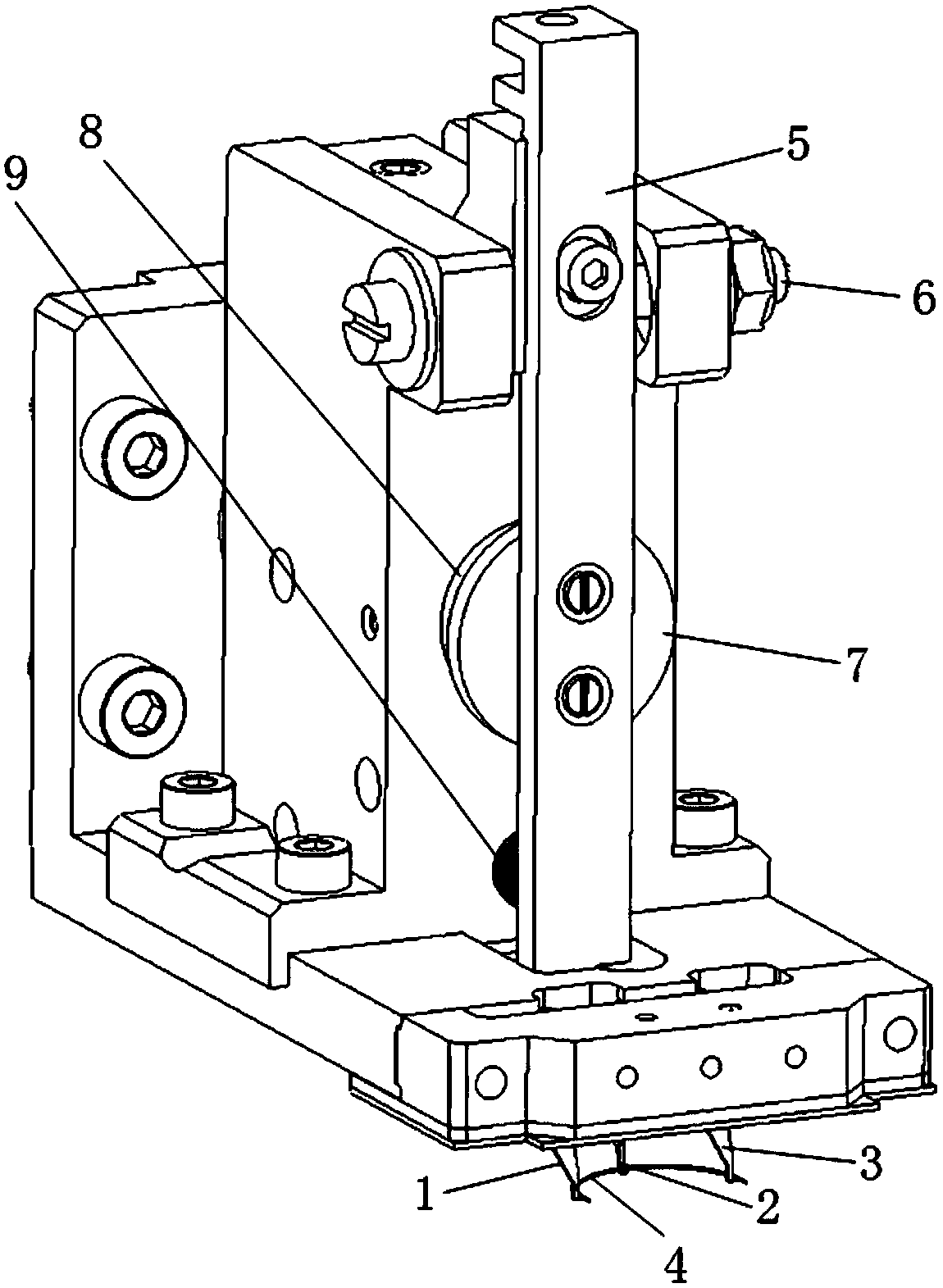

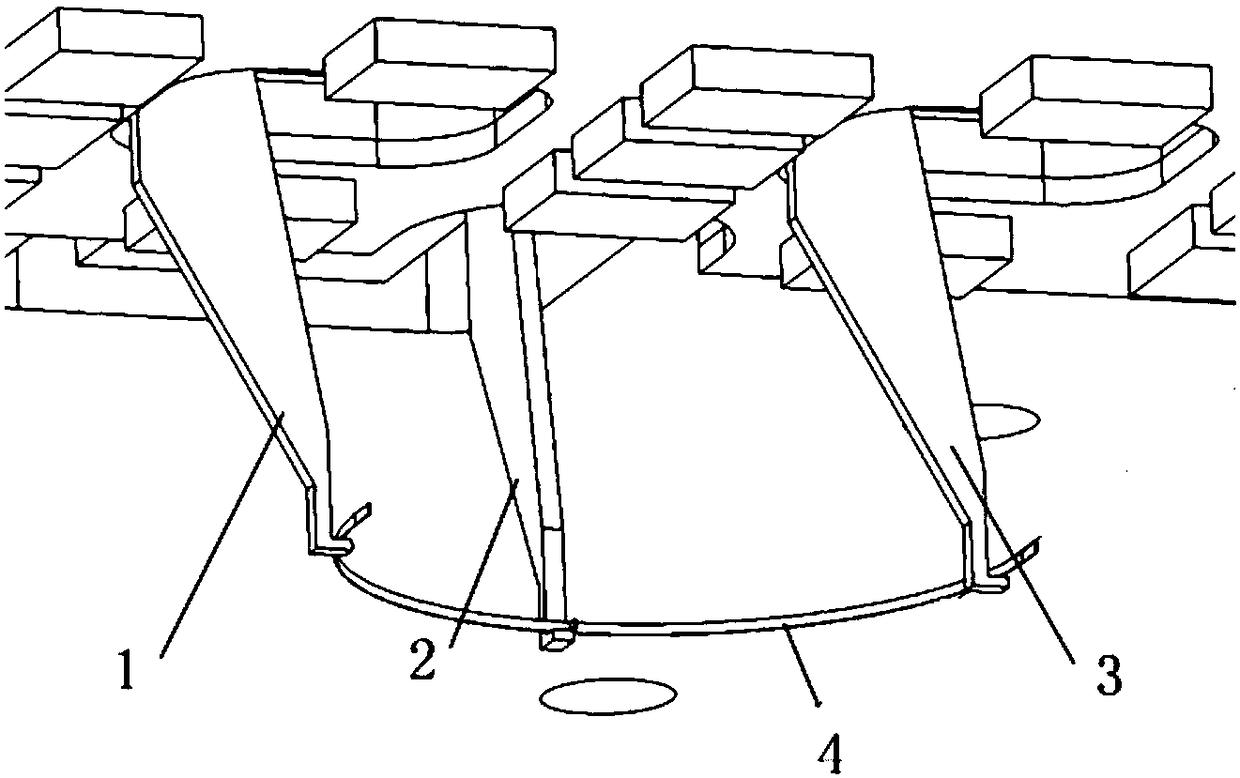

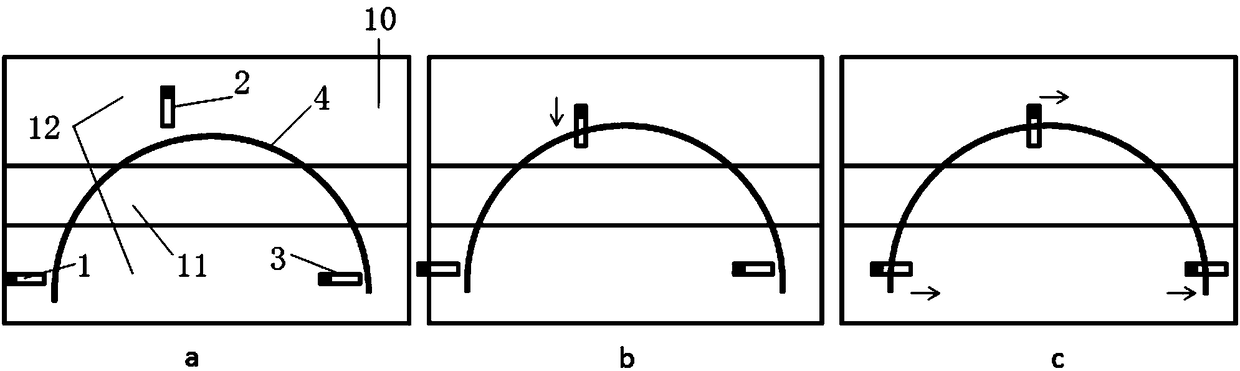

[0020] A device for the stress-free operation of a conductive hairspring, such as figure 1 As shown, it includes the operation substrate, the left claw hook 1, the middle claw hook 2, the right claw hook 3, the conductive balance spring 4 and the moving mechanism. The two L-shaped claws are on the same plane, the left claw 1 and the right claw 3 are fixedly connected to the bottom of the operation substrate, and the direction of the two claws is consistent with the insertion direction, and the distance between the left claw 1 and the right claw 3 is the same as that of the hairspring The two ends and the distance between the two grooves match; the middle claw hook 2 is fixedly connected to the bottom of the moving mechanism, and can move forward and backward with the moving mechanism.

[0021] The electromagnet seat is fixedly connected to the operation base plate, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com