Production device and production method for all-ceramic six-rowed hole combination filler

A technology for combining fillers and production devices, which is applied in chemical instruments and methods, ceramic molding machines, chemical/physical/physical-chemical processes, etc., can solve the problem of low processing and molding efficiency of all-ceramic hexagonal hole composite fillers, complicated processing and molding procedures, etc. problems, to achieve the effect of automatic molding processing and improving manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

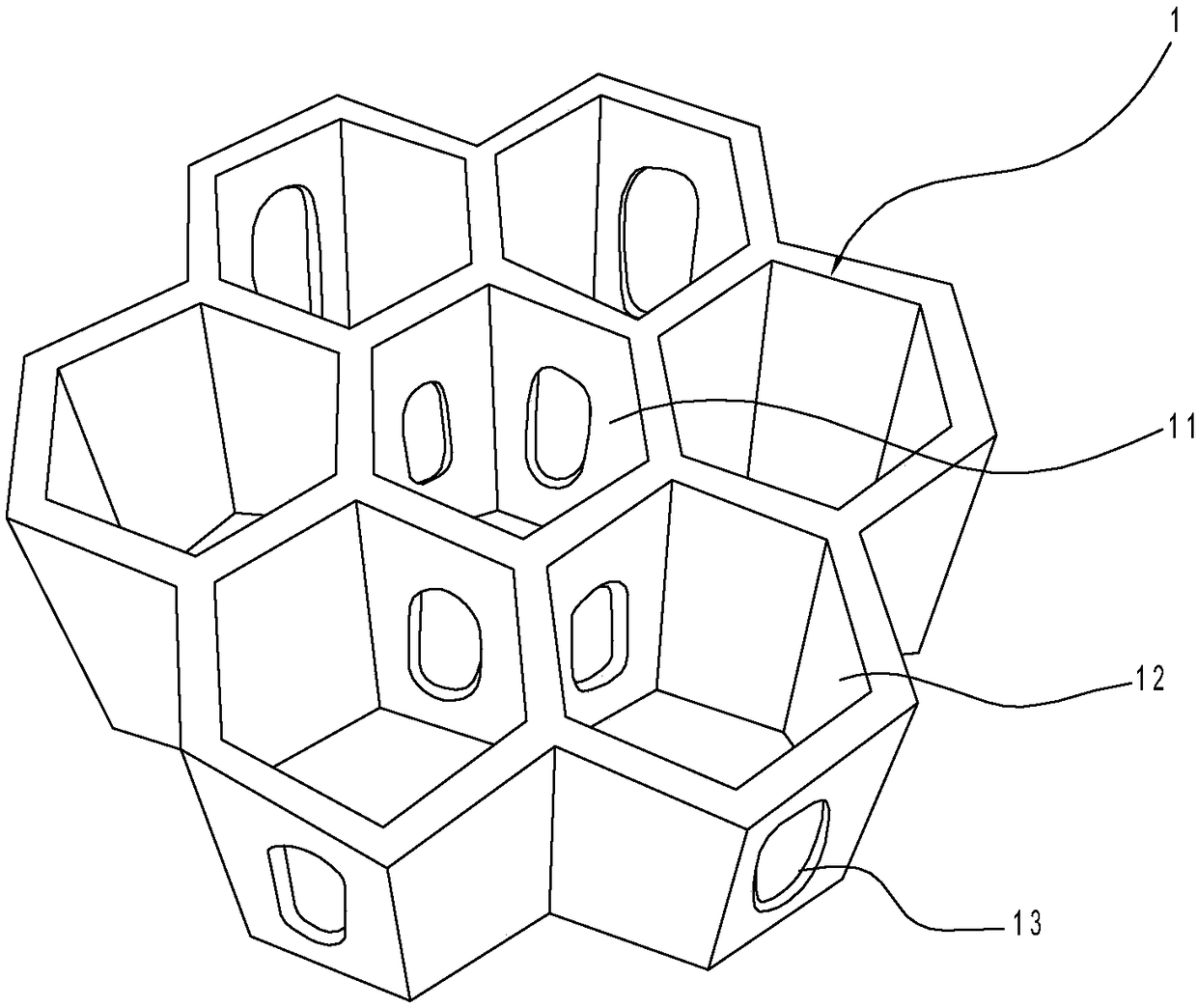

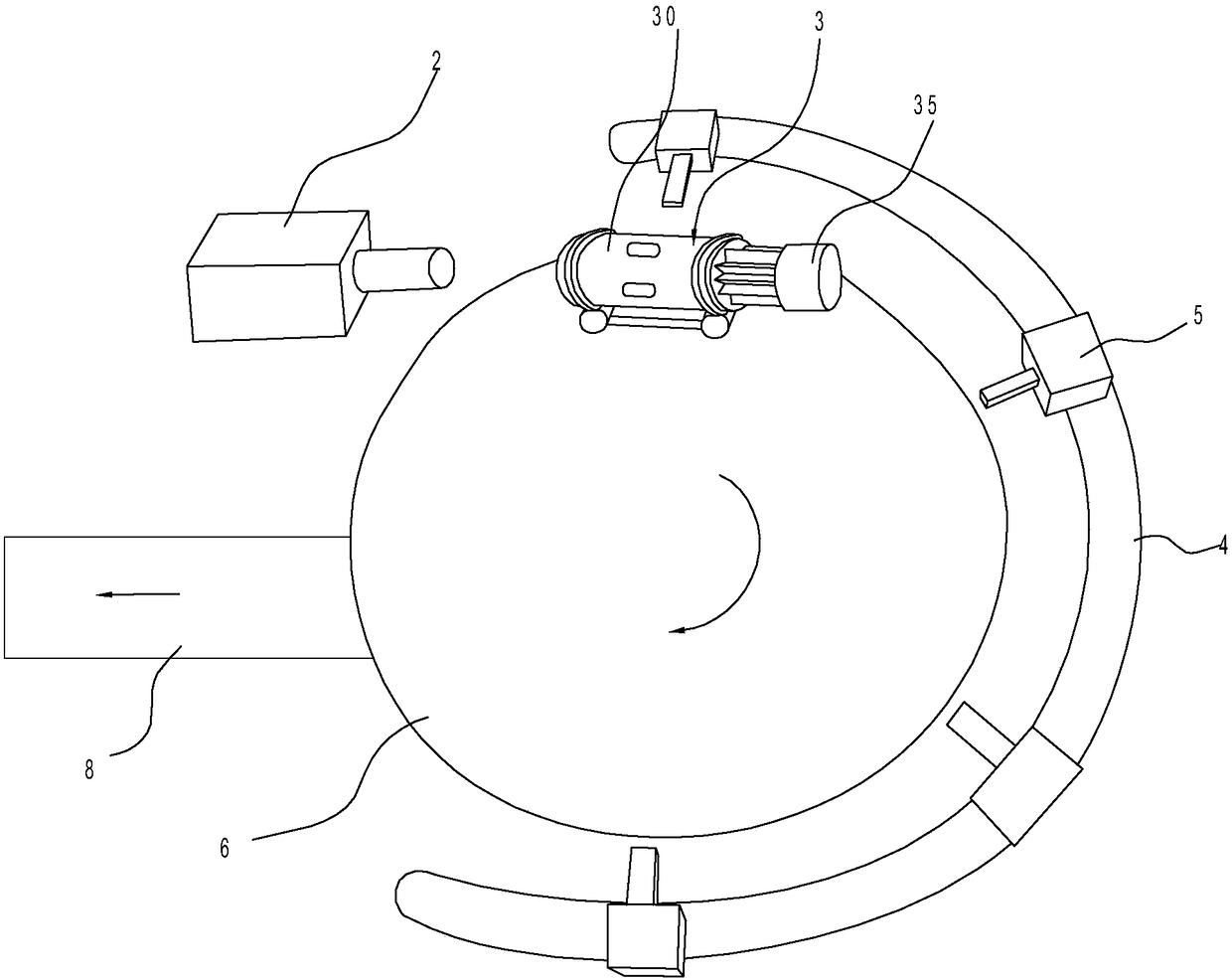

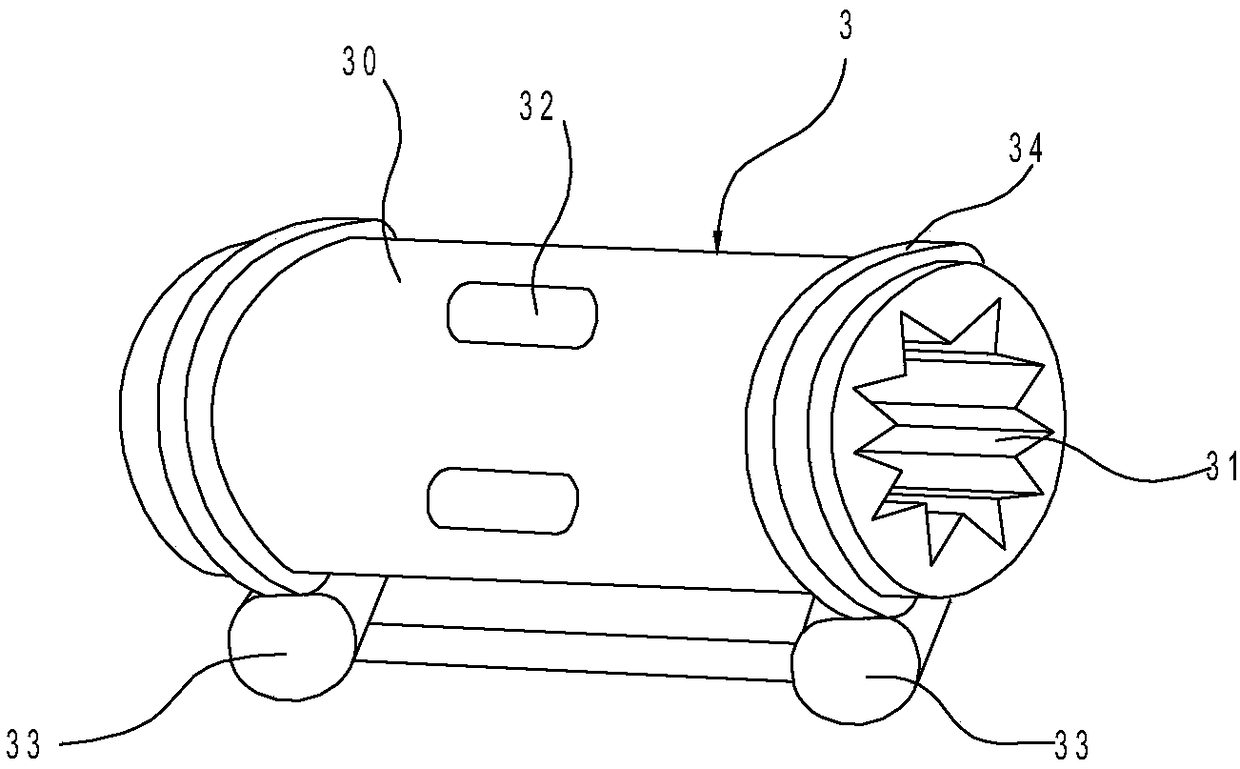

[0024] like Figures 1 to 4 As shown, the production device for all-ceramic hexagonal hole composite packing in this implementation includes an extruder 2, a cutting knife, a turntable 6, an intermittent rotation mechanism 7, a loading component 3, an arc table 4, and a hole forming component 5. Conveyor belt 8, wherein the all-ceramic hexagonal hole composite packing 1 of the present invention includes a packing body, and the packing body includes a central ring 11 and multiple sets of side rings 12, and each set of side rings 12 is relatively arranged in the circumferential direction of the central ring 11 , each side ring 12 is connected to the outer wall of the center ring 11 , and a through hole 13 penetrating the center ring 11 is opened on the same group of side rings 12 .

[0025] Wherein, the extruder 2 is used to extrude a filler bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com