Inkjet printer

A technology of inkjet printers and nozzles, applied in the field of inkjet printers, can solve the problems of increased footprint, single function, and inability to meet the needs of inkjet printing, and achieve the effects of simple and compact structure, improved functions, and favorable promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

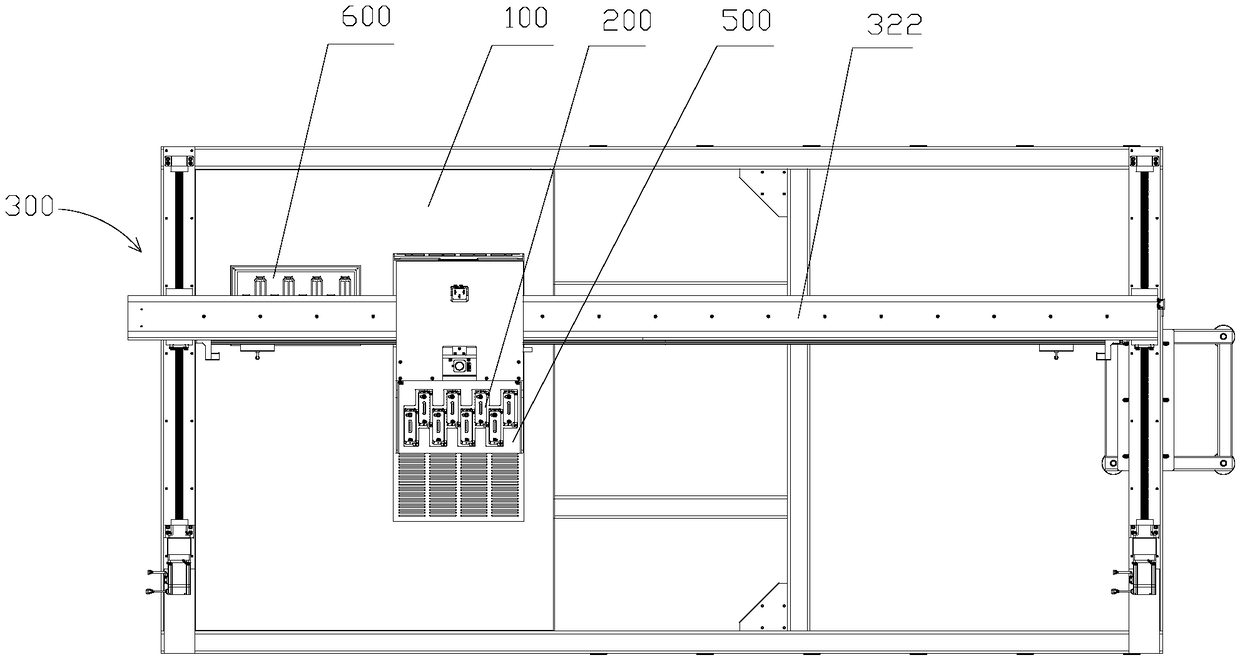

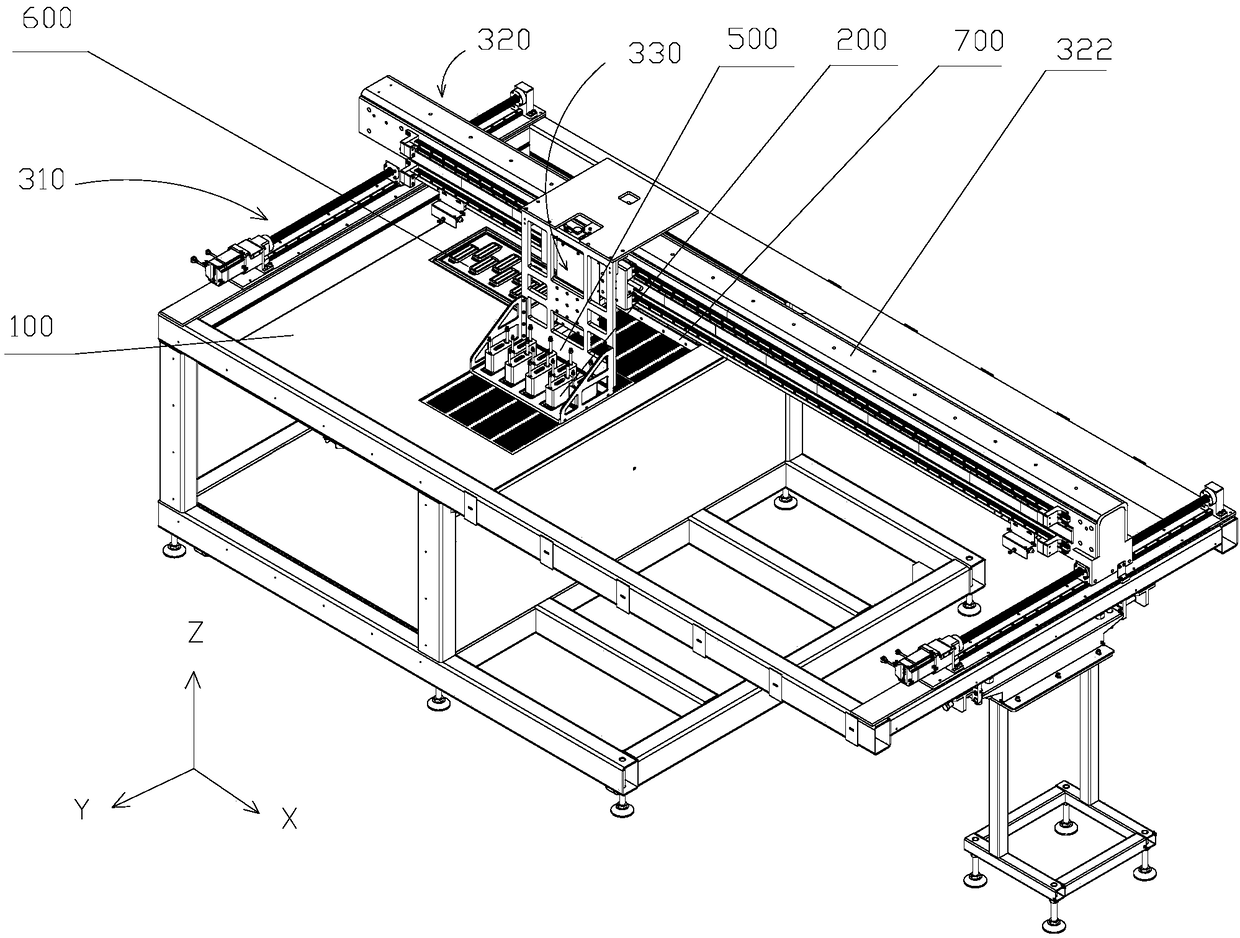

[0036] Such as figure 1 and figure 2 As shown, the inkjet printer includes a workbench 100, a spray head 200 and a three-dimensional moving device 300, and the workbench 100 is used to fix printing media. The spray head 200 is opposite to the workbench 100 and is used for printing on the printing medium. The three-dimensional moving device 300 is installed on the workbench 100, and is used to drive the print head 200 to move along the X, Y, and Z axes respectively to complete operations such as inkjet painting.

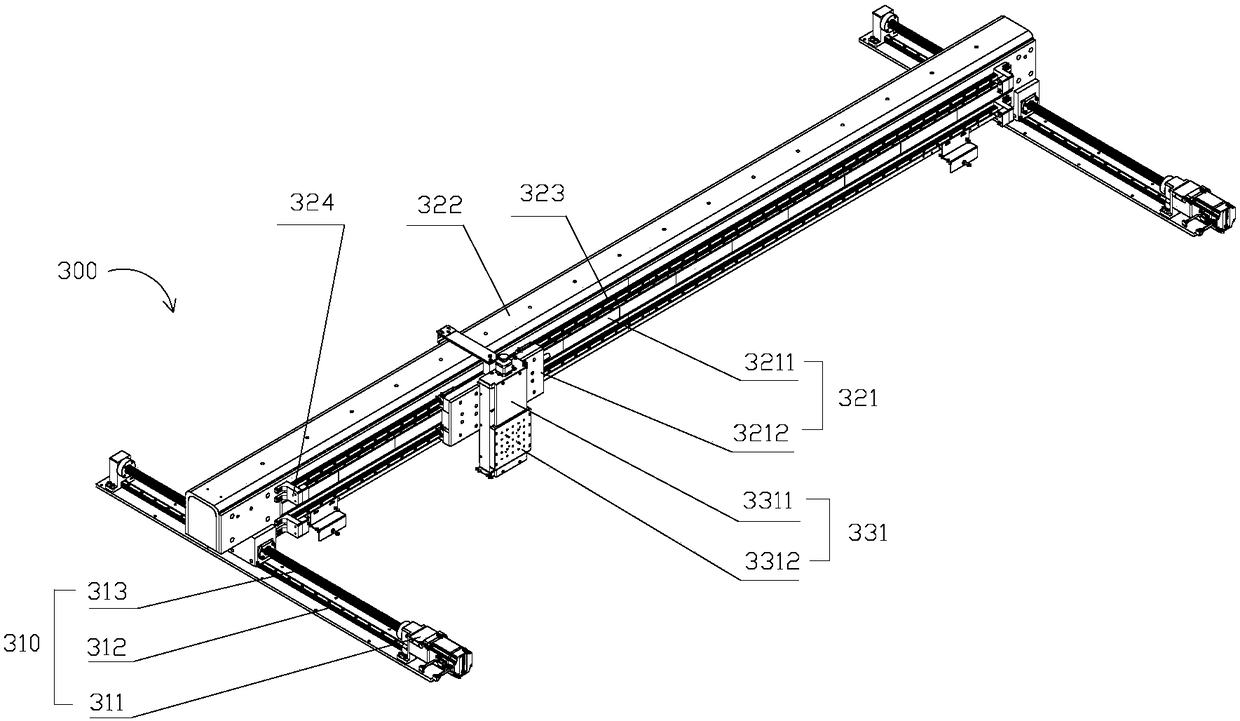

[0037] Such as figure 2 As shown, the three-dimensional moving device 300 includes a first moving device 310, a second moving device 320 and a third moving device 330, wherein the first moving device 310 is installed on the workbench 100 and is used to drive the nozzle 200 along the Y The second moving device 320 is installed on the first moving device 310, and is used to drive the nozzle 200 to move along the X-axis direction, and the third moving device 330 is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap