Wafer test device, system and method

A technology for wafer testing and wafer acceptance testing, which is applied to measurement devices, single semiconductor device testing, and electrical measurement, etc. It can solve the problems of high test risk, low wafer acceptance testing efficiency, etc., and achieve high card replacement efficiency. , The effect of improving the level of automated manufacturing and improving the efficiency of testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

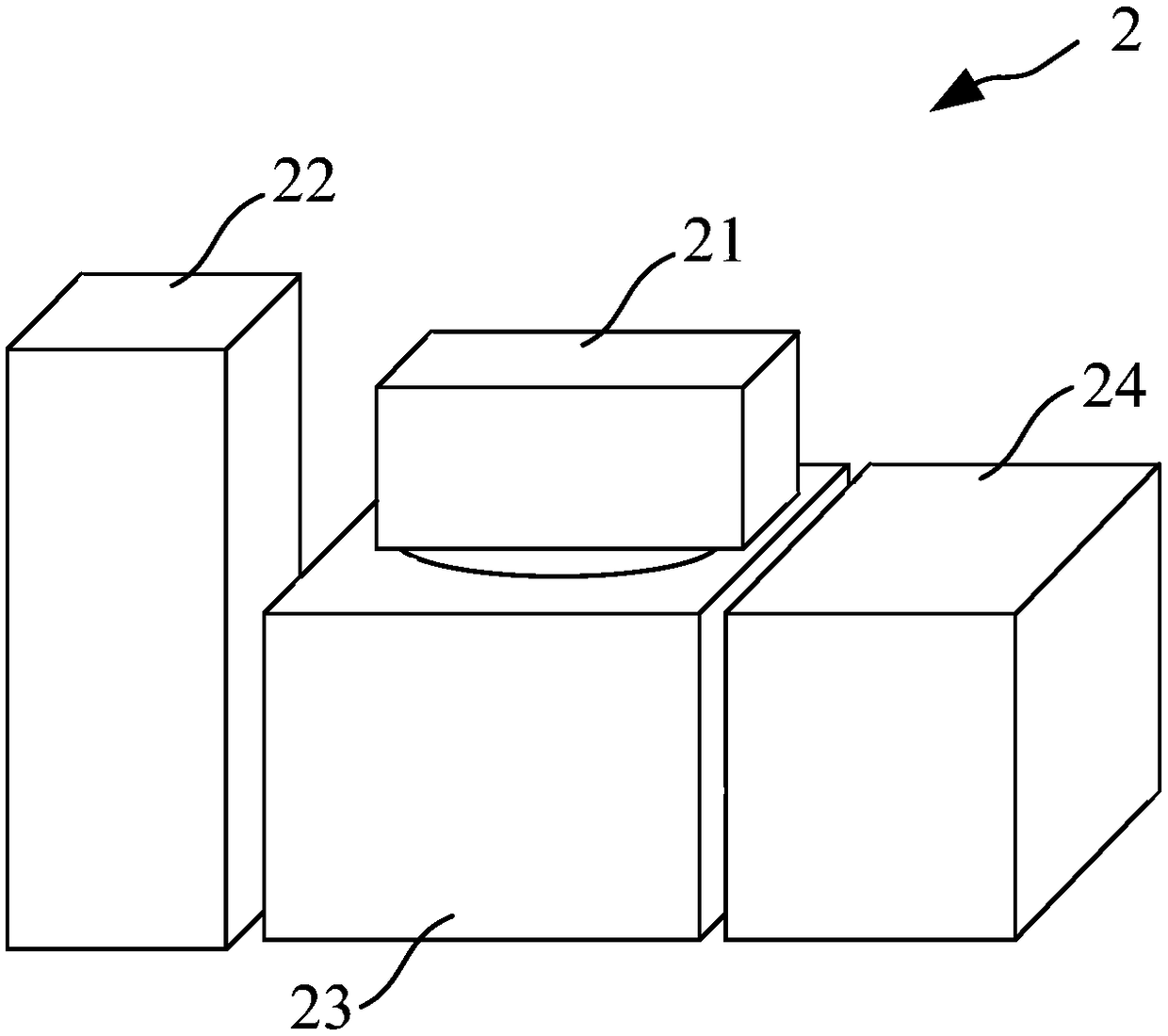

[0058] Such as image 3 As shown, the present invention provides a kind of wafer testing system 2, and described wafer testing system 2 comprises:

[0059] A wafer testing device 21 , a testing control unit 22 , a testing platform 23 and a wafer loading and unloading platform 24 .

[0060] Such as image 3 As shown, the wafer test device 21 is arranged above the test table 23, and the test structures in different directions are respectively tested by the rotation of the probe card, and different probe cards are tested by the rotation of the probe card holder. .

[0061] Specifically, as image 3 As shown, the wafer testing device 21 includes a test head 211 , a probe holder 212 , a first probe card 213 and a second probe card 214 .

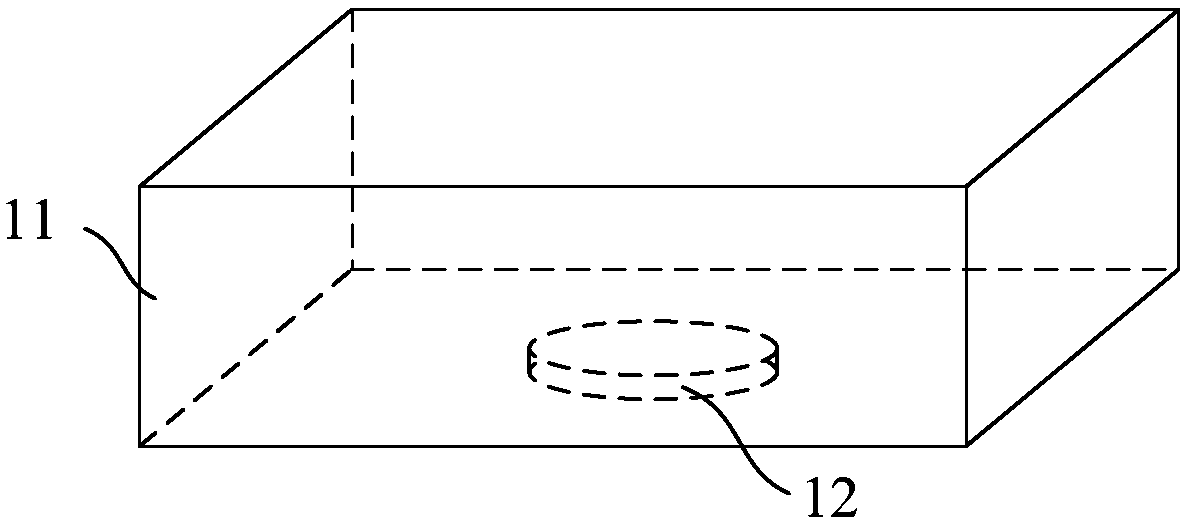

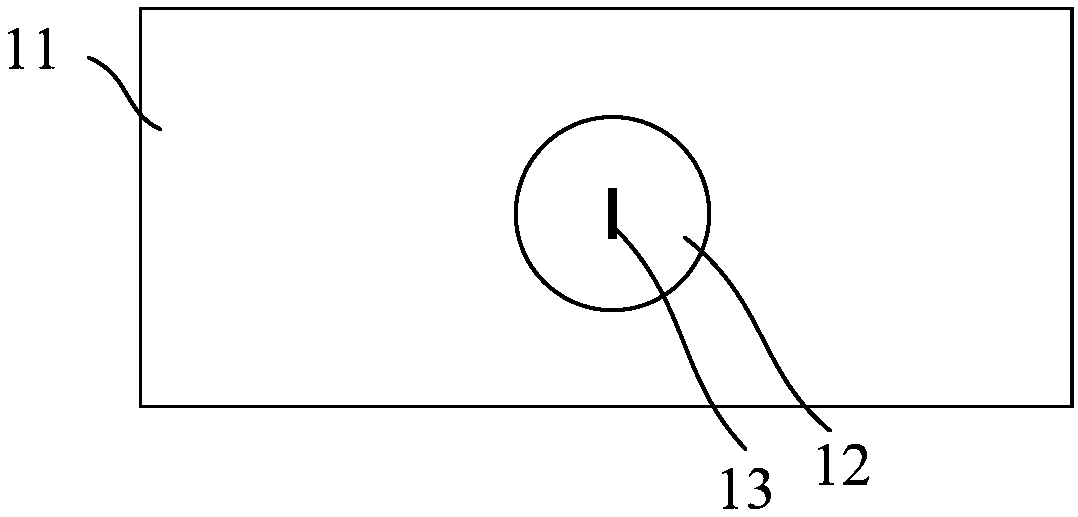

[0062] More specifically, as Figure 4 and Figure 5As shown, the test head 211 carries the probe holder 212 , the first probe card 213 and the second probe card 214 . In this embodiment, the test head 211 has a cuboid structure, but in pra...

Embodiment 2

[0073] Such as Figure 3-6 As shown, the present embodiment provides a wafer testing method, which is implemented based on the wafer testing system 2, and the wafer testing method includes:

[0074] Step S1: providing a first wafer to be tested.

[0075] Specifically, the first wafer to be tested includes test structures located in the first direction and the second direction. In this embodiment, the first wafer to be tested is a wafer after the first metal layer Metal1 is completed. , the first direction and the second direction are perpendicular to each other, and are respectively longitudinal and transverse directions.

[0076] Step S2: loading the first wafer to be tested onto the test bench 23, and performing the first test in the first direction and the second direction on the first wafer to be tested respectively, the first After the test is completed, the first wafer to be tested is unloaded from the test platform 23 .

[0077] Specifically, in this embodiment, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com