Intelligent humidity sensor

A humidity sensor and intelligent technology, applied in the sensor field, can solve the problems of inconsistent accuracy, low consistency and stability of humidity sensors, low production efficiency, etc., to improve debugging accuracy, improve production process and work efficiency, and save repeated effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

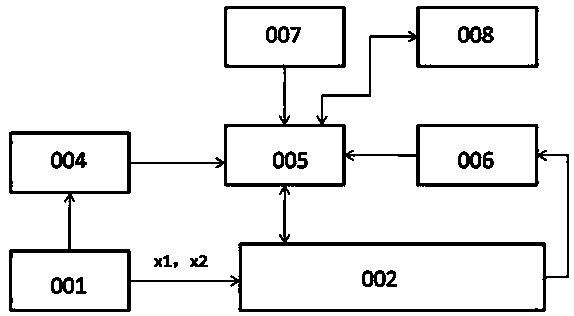

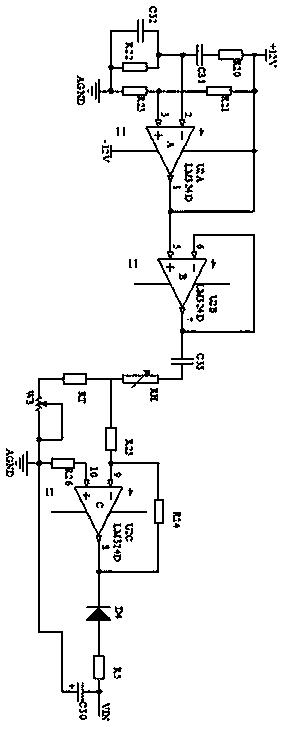

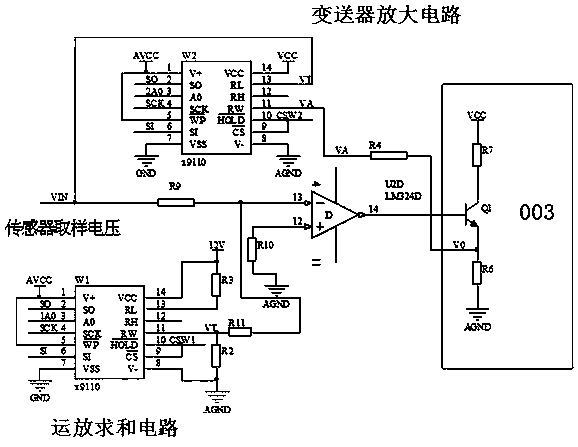

[0067] An intelligent humidity sensor, its structure has humidity sensor sampling circuit 001, amplification control circuit 002, A / D conversion front input circuit 004, single chip microcomputer system 005, A / D conversion front output circuit 006, man-machine dialogue unit 007, The interface module 008 is composed; wherein, the first signal output end of the humidity sensor sampling circuit 001 is connected with the first signal input end of the amplification control circuit 002, and the second signal output end of the humidity sensor sampling circuit 001 is connected with the A / D conversion front input The signal input end of the circuit 004 is connected, the signal output end of the A / D conversion pre-input circuit 004 is connected with the first signal input end of the single-chip microcomputer system 005, the second signal input end of the single-chip microcomputer system 005 is connected with the signal of the man-machine dialogue unit 007 The output terminals are connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com