Solid-liquid separation device for garbage

A technology of solid-liquid separation and garbage, applied in manufacturing tools, grain processing, presses, etc., can solve the problem of cutting knife garbage entanglement, and achieve the effect of reducing resistance, easy to rise, and improving cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Further detailed explanation through specific implementation mode below:

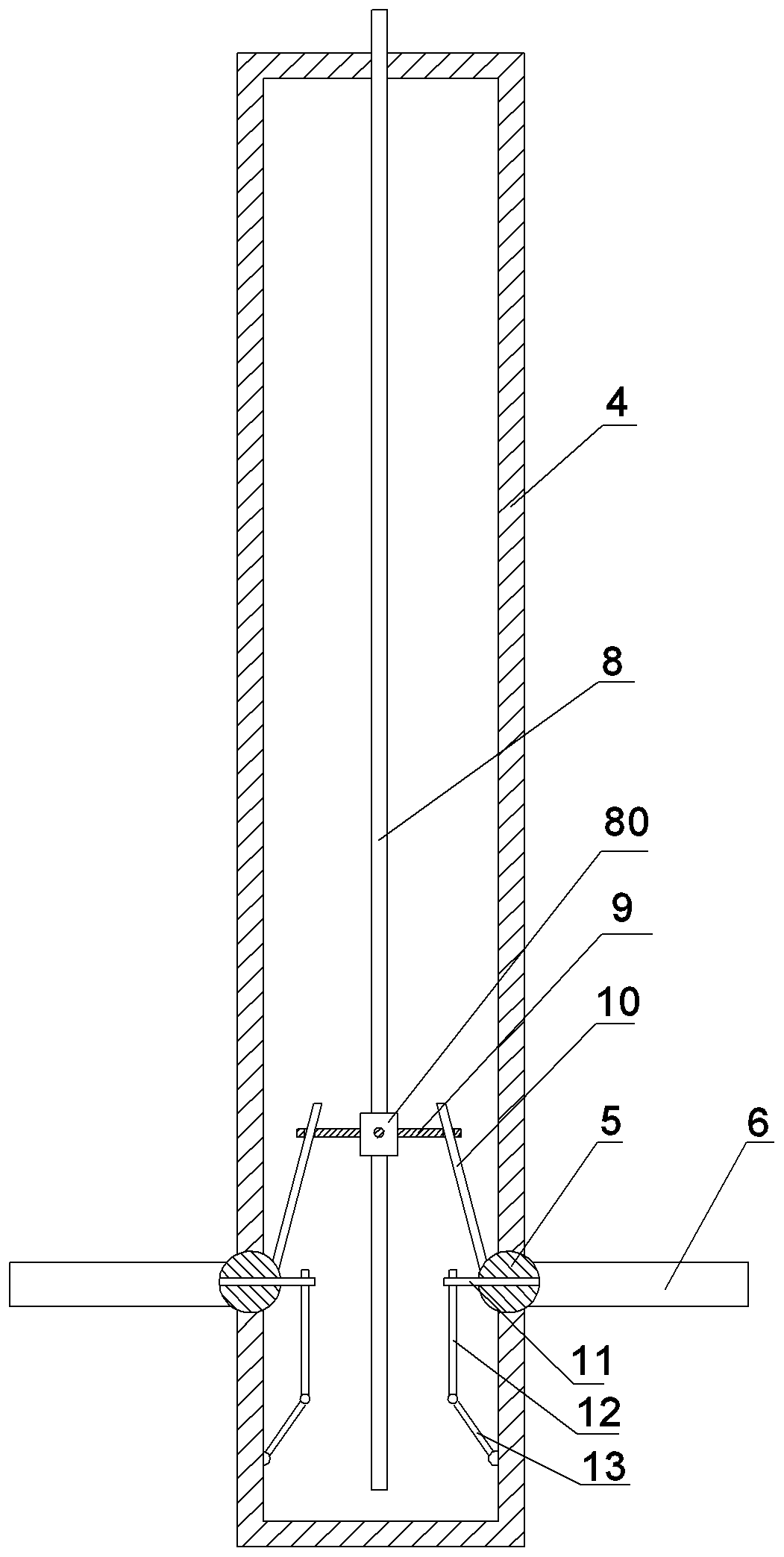

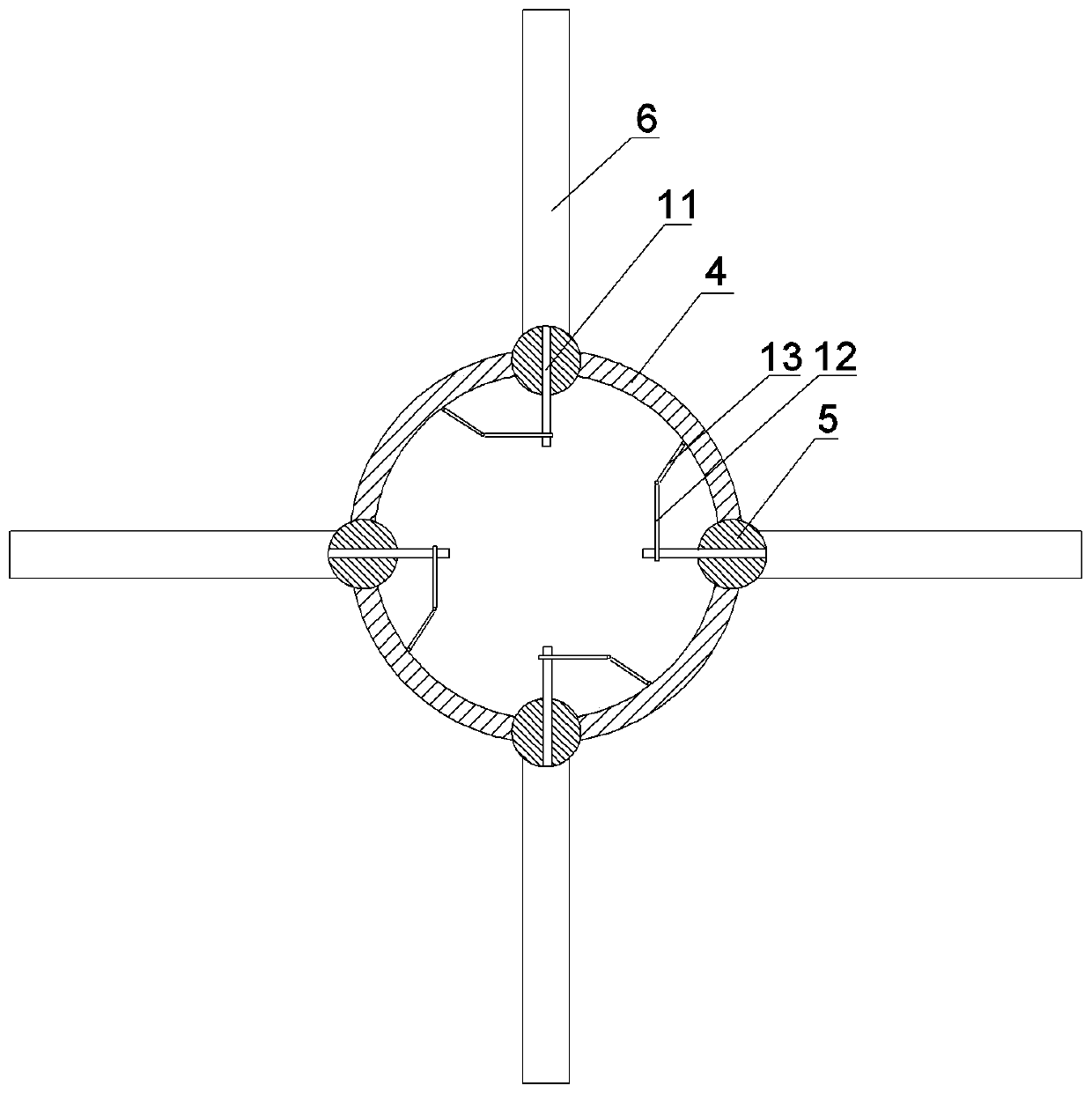

[0024] The reference signs in the accompanying drawings of the specification include: upper box body 1, lower box body 2, pressure plate 3, rotating shaft 4, sealing ball 5, crushing leaf 6, baffle plate 7, water hole 70, lead screw 8, nut 80, Adjusting rod 9 , first connecting rod 10 , support shaft 11 , connecting arm 12 , second connecting rod 13 .

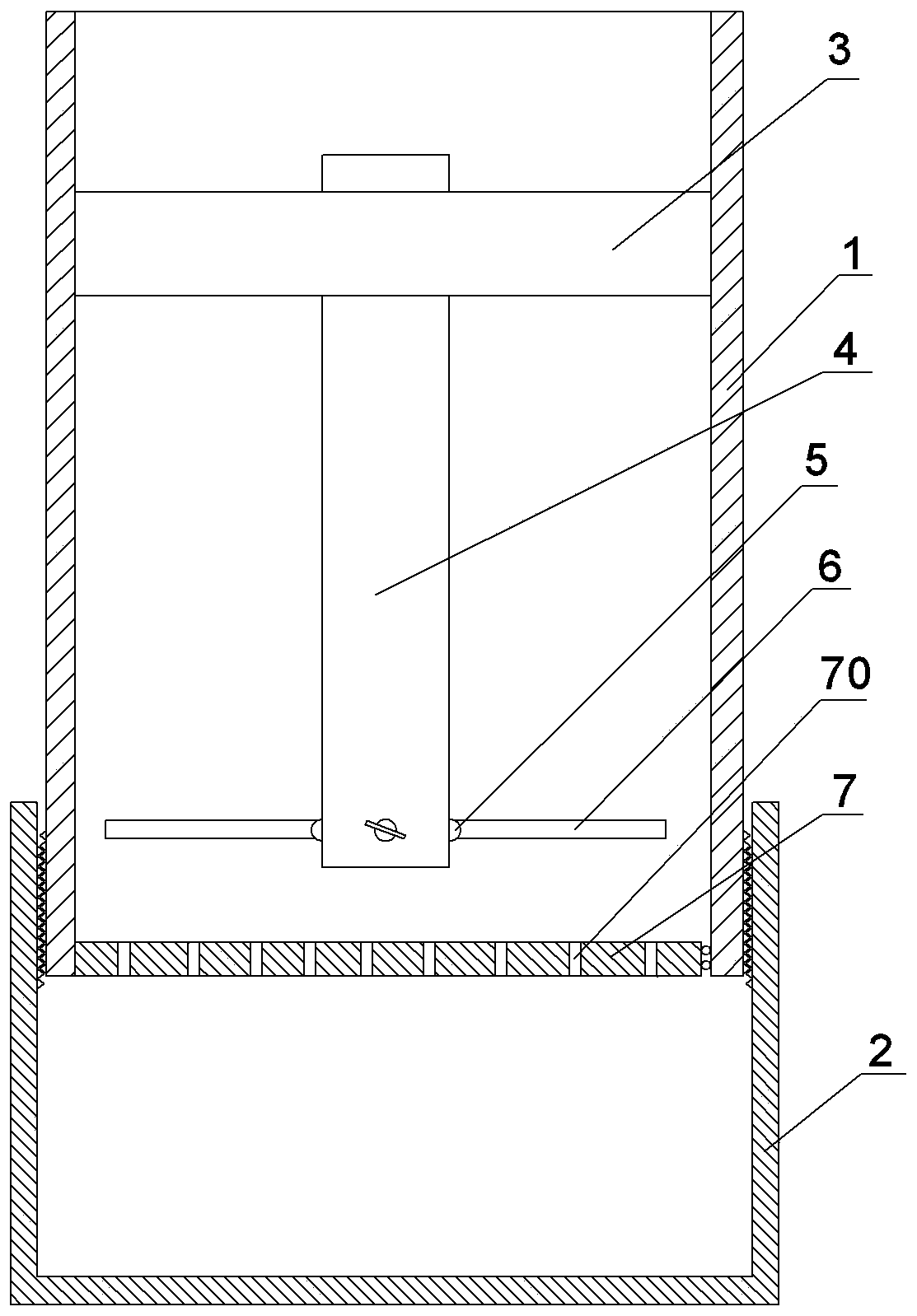

[0025] Such as figure 1 As shown, the garbage solid-liquid separation device of the present embodiment comprises a box body, and a baffle plate 7 is hinged in the box body, and the baffle plate 7 is densely covered with water holes 70, and the box body above the baffle plate 7 is the upper box body 1, and the baffle plate 7 The box below the plate 7 is the lower box 2, the upper box 1 is screwed to the lower box 2, and the baffle plate 7 and the side wall of the upper box 1 are locked by buckles. A pressure plate 3 is slidably arranged in the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com