Folding mechanism for cover wrapping machine

A technology of cover machine and folding plate, which is applied in book case for binding, printing, book binding, etc. It can solve the problems of large floor area, huge machine body, and complicated structure of folding mechanism, so as to achieve convenient material picking, Improve the effect of the hemming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. Wherein the same components are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "bottom" and "top "Face", "inner" and "outer" refer to directions toward or away from, respectively, the geometric center of a particular component.

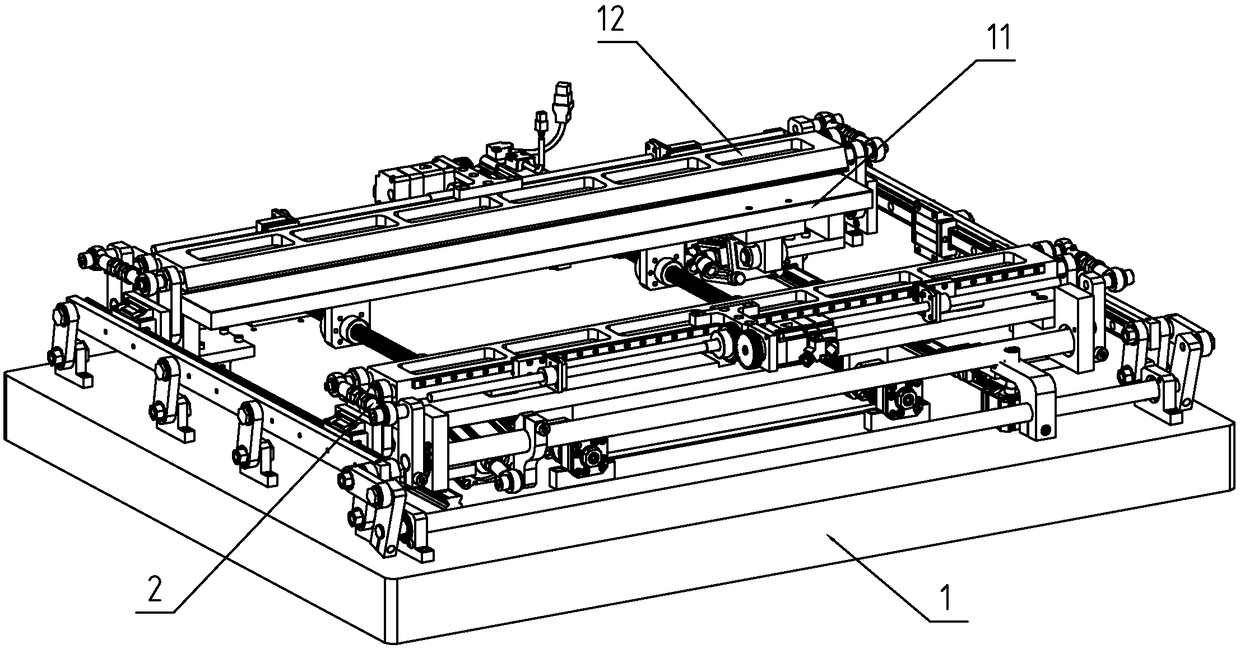

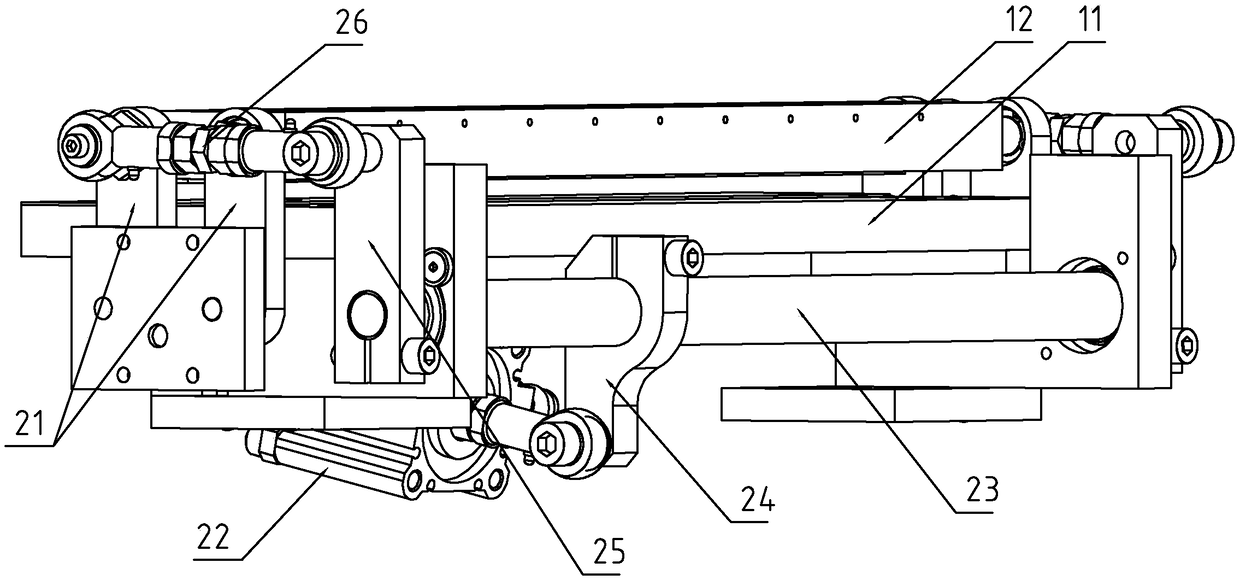

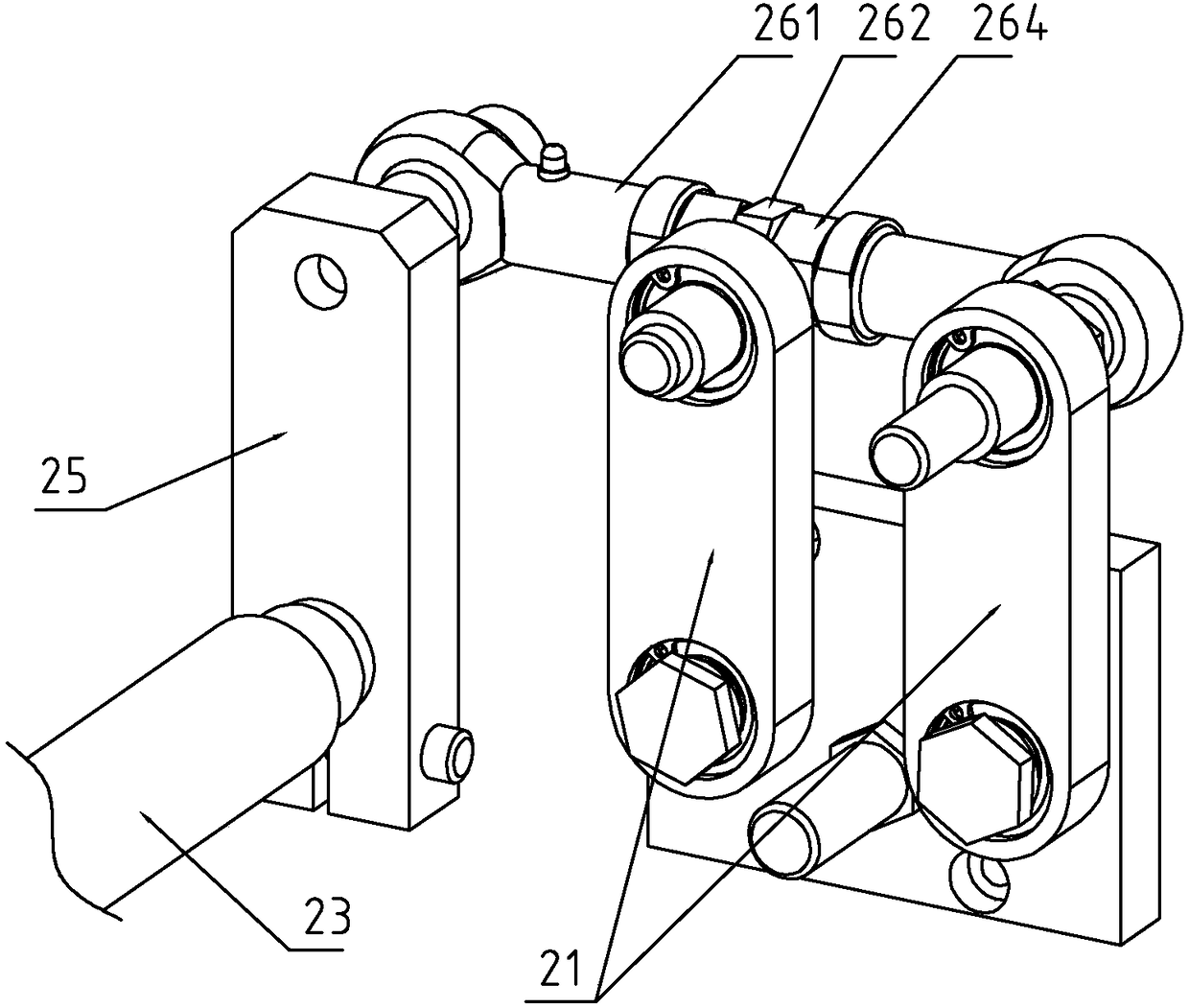

[0016] refer to Figure 1-4 As shown, a hemming mechanism for a cover machine includes a bracket 1, a lower flap 11 arranged on the bracket 1, an upper flap 12 above the lower flap 11, the upper flap 12 and the lower flap 11 are arranged in parallel, the gap between the upper folding plate 12 and the lower folding plate 11 is smaller than the width of the folded edge of the face paper protruding from the cardboard, and there are two upper folding plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com