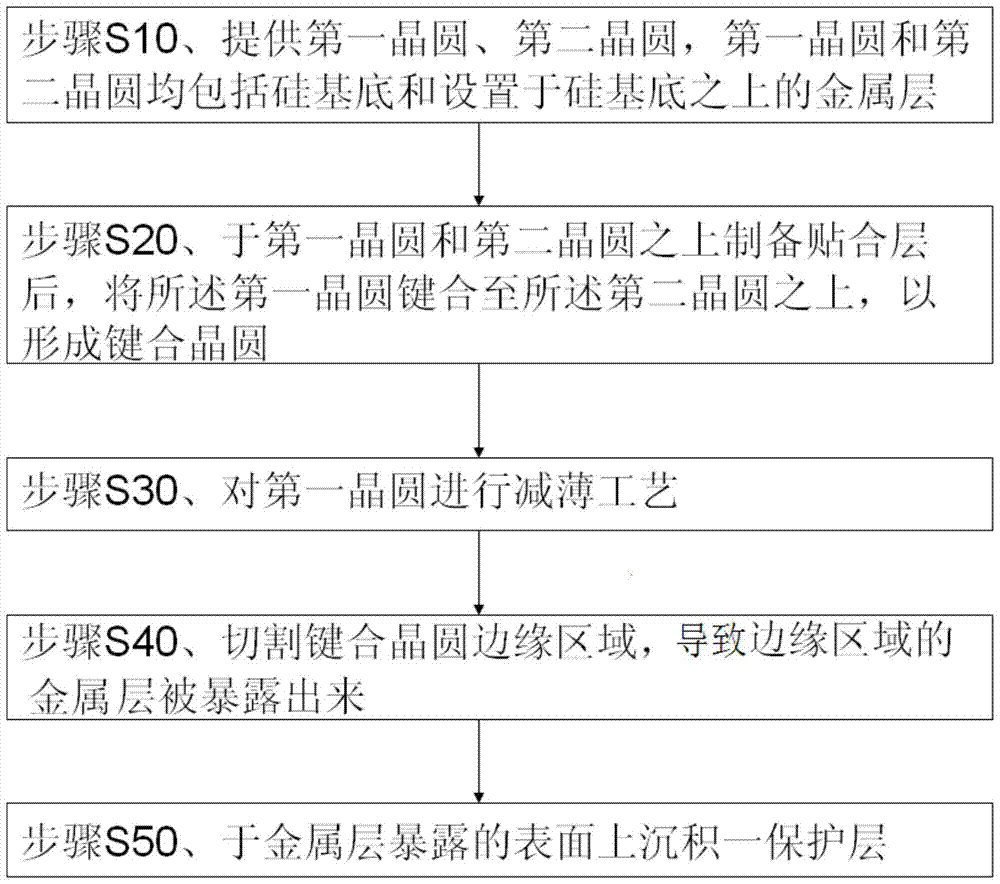

A wafer bonding method

A wafer and bonding technology, which is applied in the photoengraving process of the pattern surface, the process for producing decorative surface effects, and decorative arts, etc. The effect of avoiding cracking, improving yield and improving effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0043] A specific embodiment is listed: this embodiment is only an embodiment of the present invention, and is not intended to specifically limit the present invention.

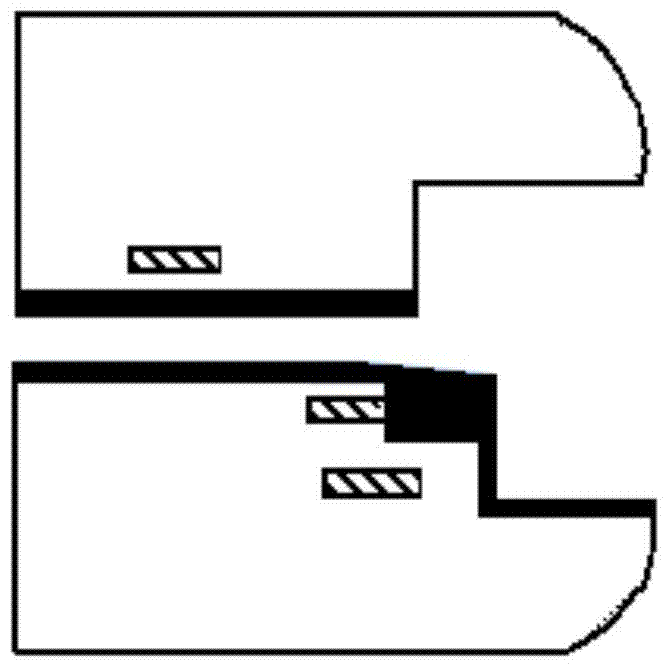

[0044] Such as Figure 2a As shown, two wafers to be bonded are provided. Here, for the convenience of description, the two wafers are respectively referred to as a first wafer and a second wafer.

[0045] Such as Figure 2b As shown, first, the bonding layers of the two wafers are bonded to each other. That is, the bonding layer of the first wafer is bonded and connected to the bonding layer of the second wafer.

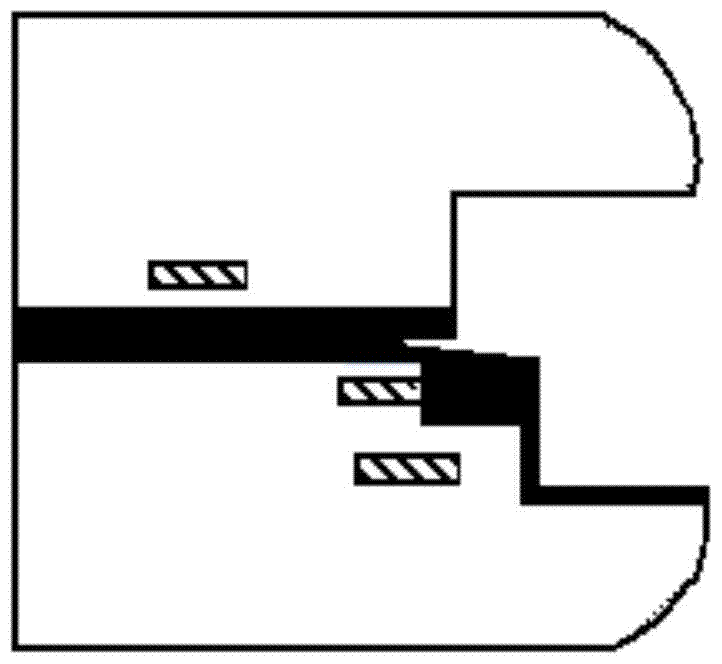

[0046] Such as Figure 2c As shown, thinning treatment is performed on the surface of the first wafer at the upper end to remove the silicon deposition layer with a predetermined thickness. At the same time, during the thinning process, a retracted incision chamfer is produced on the bonding layer. The retracted type The shape of the notch chamfer is different due to the different processes use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com