New energy automobile elevating mechanism

A new energy vehicle, lifting device technology, applied in the direction of lifting frame, lifting device, lifting equipment safety device, etc., can solve the problem of undisclosed anti-drop protection measures, etc., to achieve the effect of safe use and prevent accidental falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

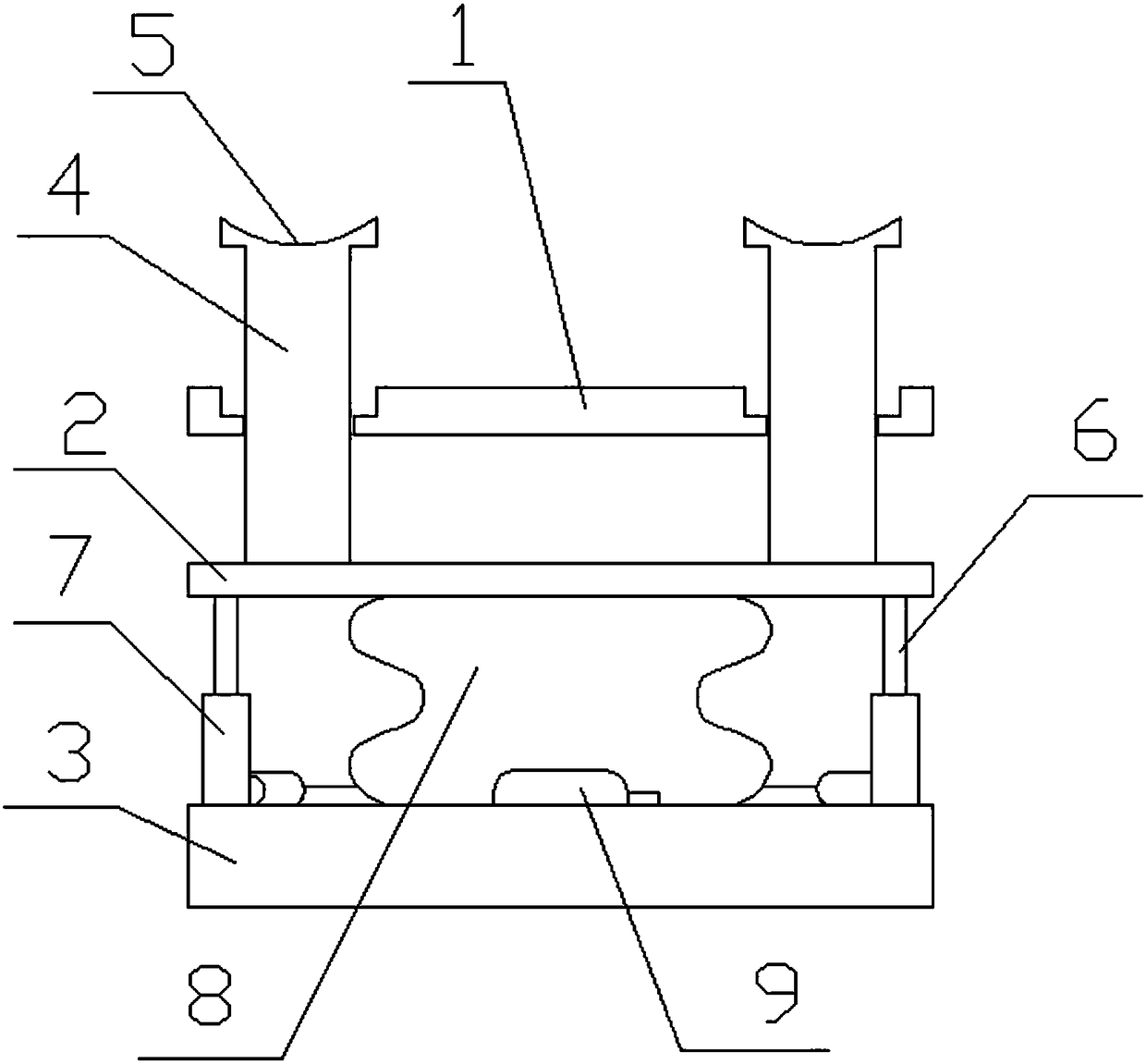

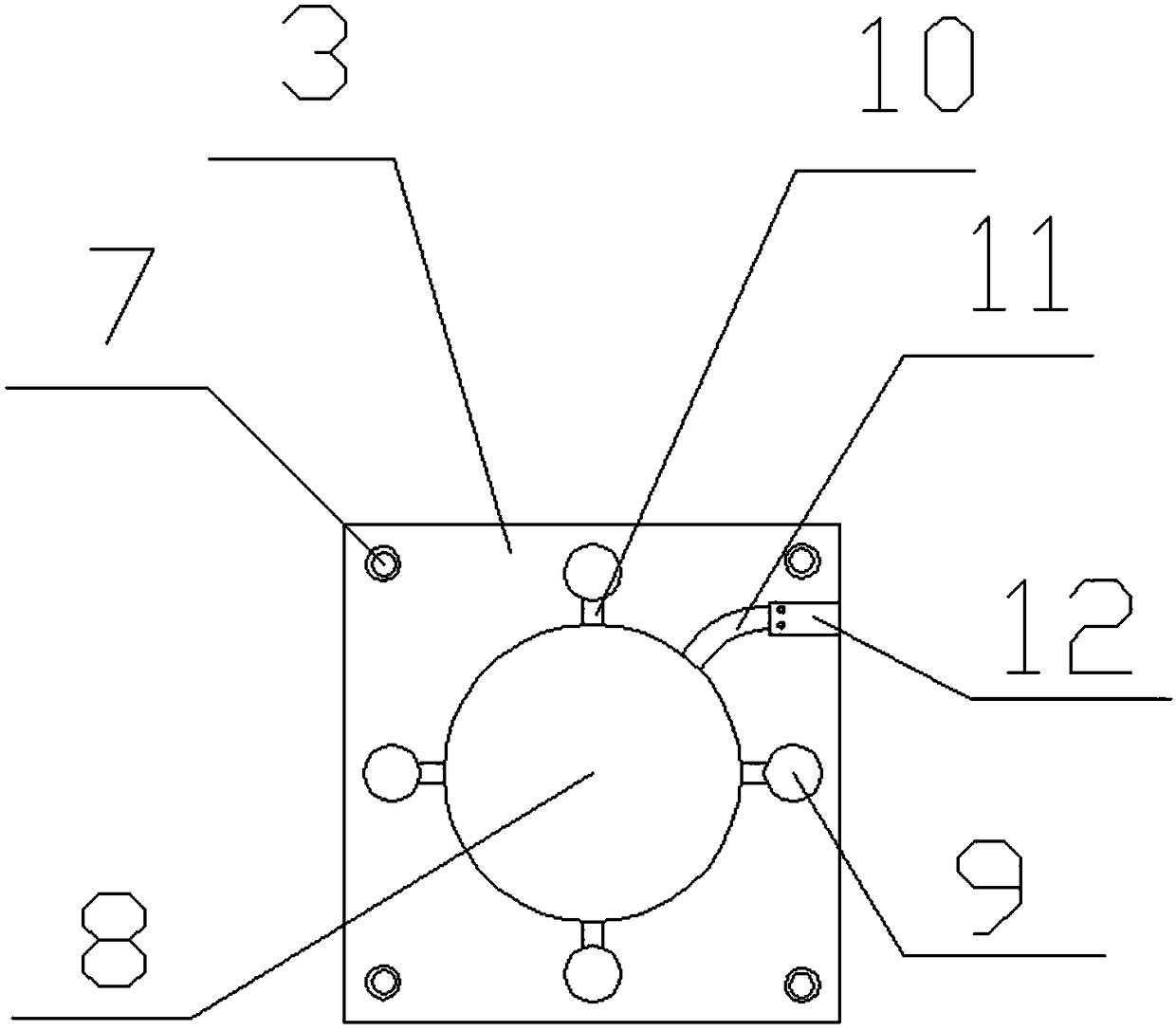

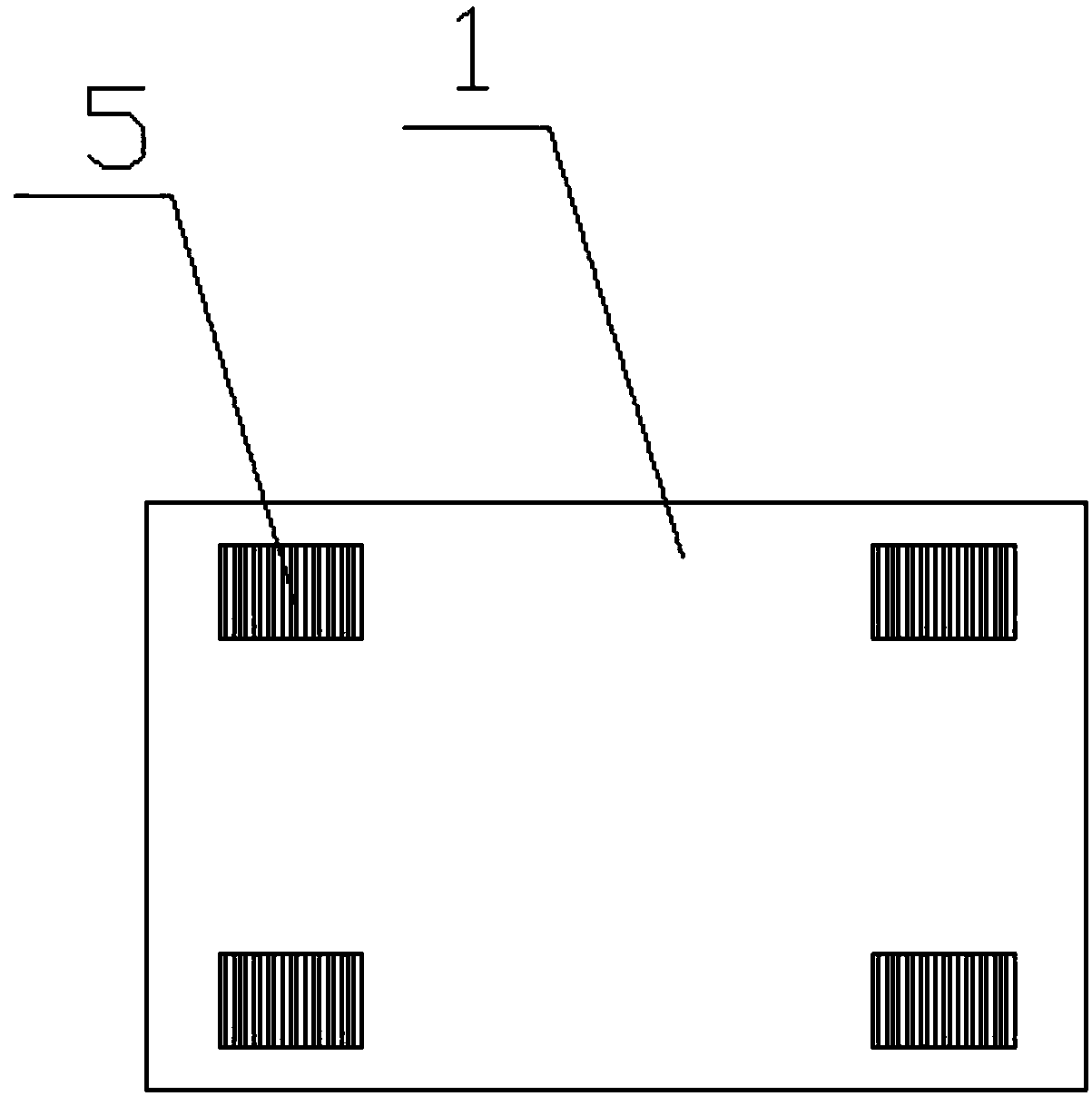

[0020] Such as Figure 1 to Figure 4 As shown, a lifting mechanism for a new energy vehicle includes a limiting plate 1, a lifting plate 2, a positioning plate 3, a lifting device and a limiting device. Keep the stable lifting of the device, the positioning plate 3 can make the device stable, the limiting plate 1 is arranged on the ground, the lifting plate 2 is arranged under the limiting plate 1, and the positioning plate 3 is arranged on the bottom of the lifting plate 2 Below, the upper surface of the lifting plate 2 is provided with four support columns 4 that are slidably connected with the limit plate 1. The support columns 4 play a supporting role and can prevent the vehicle from shaking after the vehicle is lifted. The lifting device is located at Between the lifting plate 2 and the positioning plate 3, the lifting device includes a rubber tube 8, an air pump 9 and an exhaust pipe 11, and the rubber tube 8 is inflated through the air pump 9, so that the rubber tube 8 ...

Embodiment 2

[0026] Such as Figure 1 to Figure 4As shown, a lifting mechanism for a new energy vehicle includes a limiting plate 1, a lifting plate 2, a positioning plate 3, a lifting device and a limiting device. Keep the stable lifting of the device, the positioning plate 3 can make the device stable, the limiting plate 1 is arranged on the ground, the lifting plate 2 is arranged under the limiting plate 1, and the positioning plate 3 is arranged on the bottom of the lifting plate 2 Below, the upper surface of the lifting plate 2 is provided with four support columns 4 that are slidably connected with the limit plate 1. The support columns 4 play a supporting role and can prevent the vehicle from shaking after the vehicle is lifted. The lifting device is located at Between the lifting plate 2 and the positioning plate 3, the lifting device includes a rubber tube 8, an air pump 9 and an exhaust pipe 11, and the rubber tube 8 is inflated through the air pump 9, so that the rubber tube 8 e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com