Composite insulator climbing system

A technology for composite insulators and insulator sheds, which is applied in the field of composite insulator climbing systems, can solve problems such as inability to detect internal defects of composite insulators, easy damage to the anti-fouling coating on the surface of insulators, and high requirements for insulator string shape and position errors. Achieve the effect of reducing labor intensity, easy popularization and application, and fast moving speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

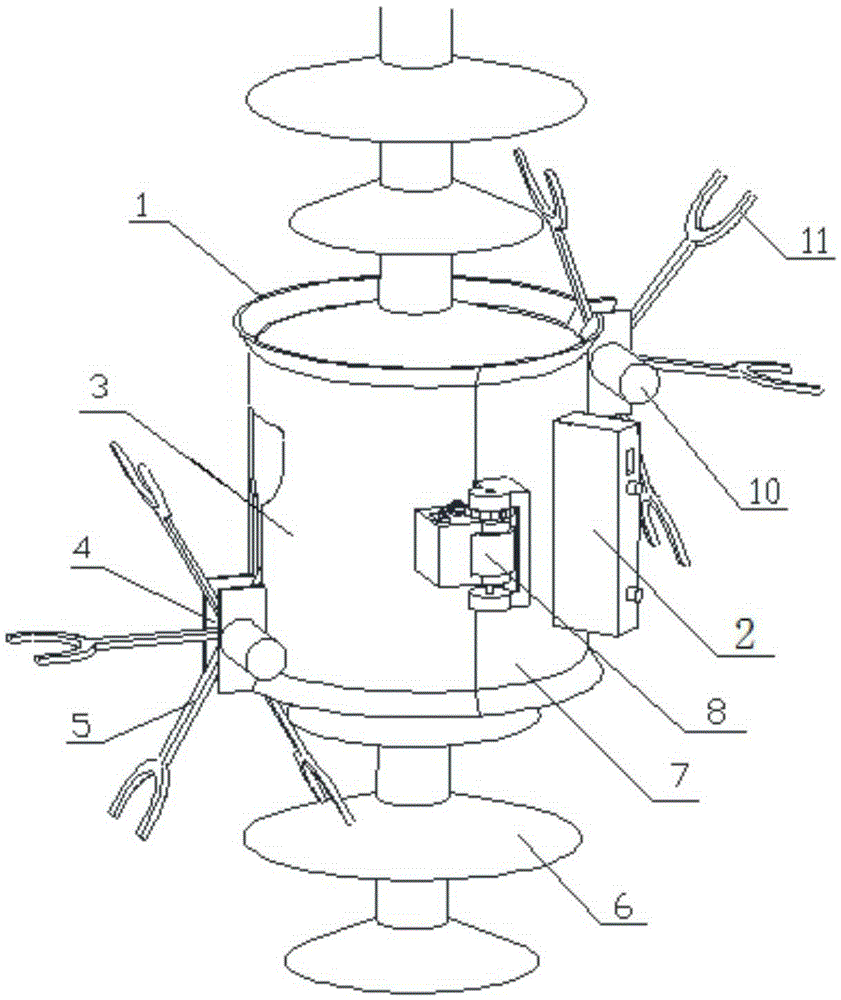

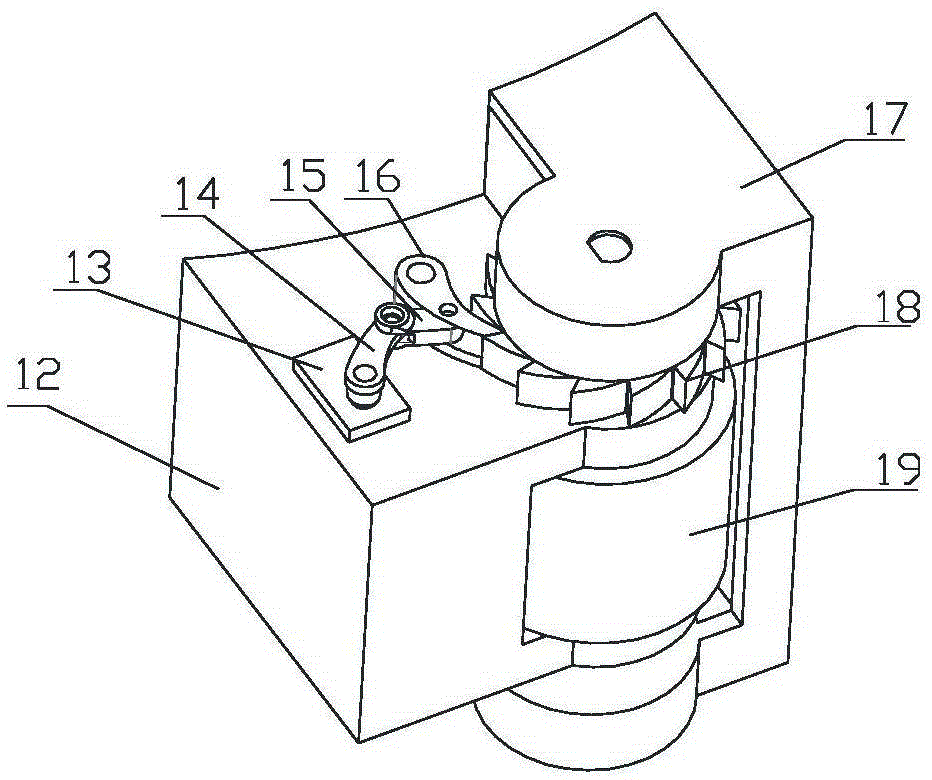

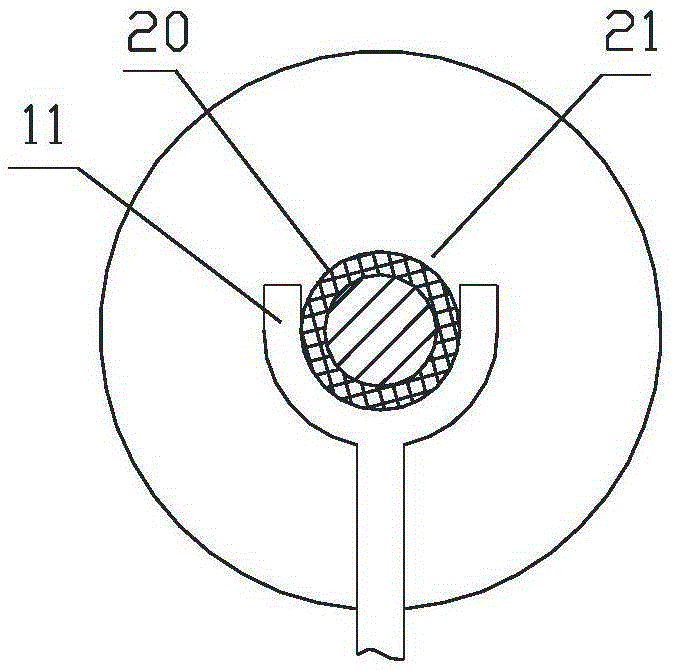

[0036] Such as figure 1 As shown, the composite insulator detection mechanism is mainly composed of an embrace frame 1, a moving mechanism 4, an opening and closing locking mechanism 8, and a battery control box 2. The ring frame 1 is composed of a first semicircle frame 3 and a second semicircle frame 7. The ring frame The inner ring fits the outer edge of the composite insulator string 6, and the first semicircular frame 3 and the second semicircular frame 7 are symmetrically arranged, connected by an opening and closing locking mechanism 8, which controls the opening and closing of the annular frame, and the locking mechanism controls the ring The frame is locked in the closed state and plays a role of safety protection. The moving mechanism 4 is composed of two identical parts symmetrically arranged up and down, and each part is composed of a movin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com