Forklift cargo storing and taking method and device based on obstacle avoidance sensor

An obstacle avoidance sensor and access method technology are applied in the field of forklift cargo access methods and devices based on obstacle avoidance sensors, which can solve the problem of inability to effectively and quickly identify the number of pallet layers, and achieve convenient debugging, strong versatility, and algorithms. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

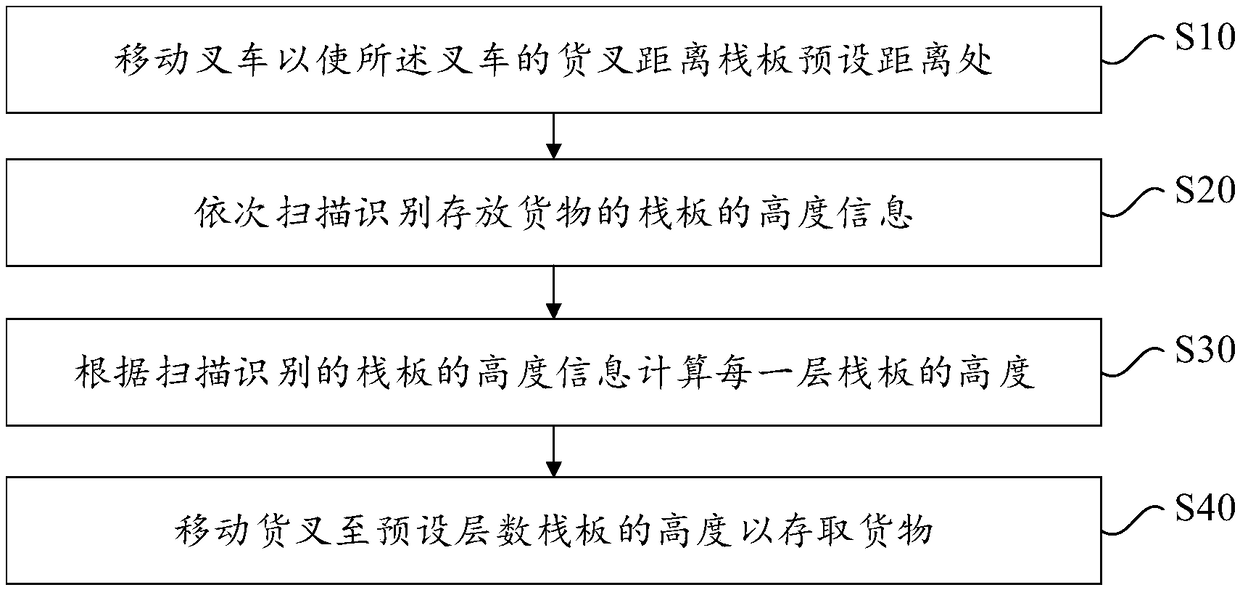

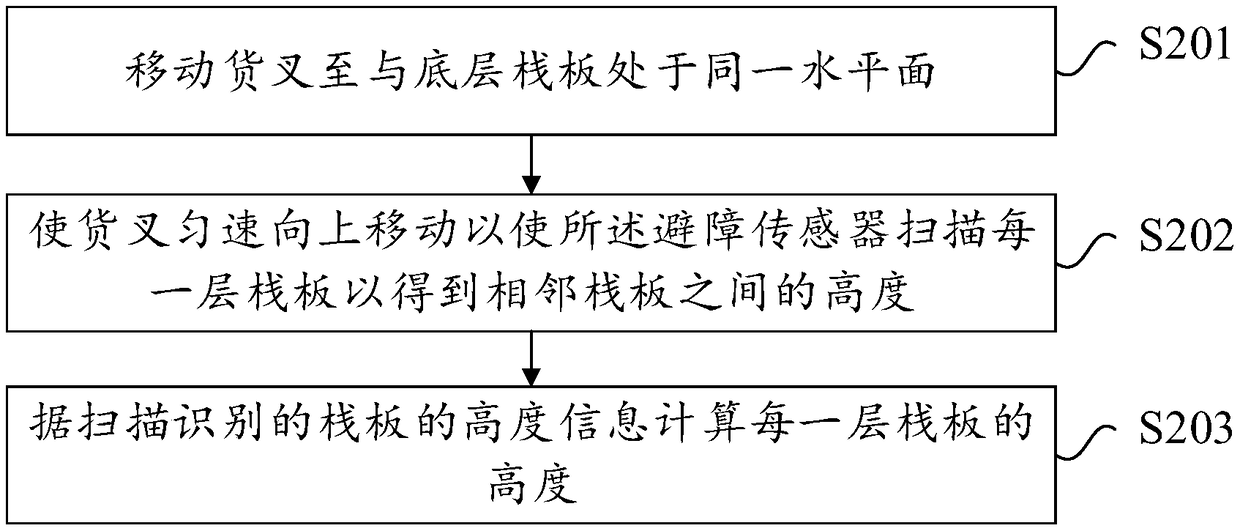

[0042] This embodiment provides a method for accessing goods by a forklift based on an obstacle avoidance sensor, so as to improve the problem that the existing forklift cannot accurately and quickly identify the height of pallet layers. In order to obtain better flexibility when forking goods of different heights.

[0043] see figure 2 , figure 2 The forklift cargo access method based on the obstacle avoidance sensor provided in this embodiment is shown, and the forklift cargo access method based on the obstacle avoidance sensor includes steps S10 to S40.

[0044] Step S10: moving the forklift so that the forks of the forklift are at a preset distance from the pallet.

[0045] In this embodiment, the forklift, that is, the AGV with the fork, can transport the goods to the preset position and store them on the pallet shelf, or move to a specific pallet position, and store the goods on the pallet The goods are taken out. For different shelves, the number of pallet layers ...

no. 2 example

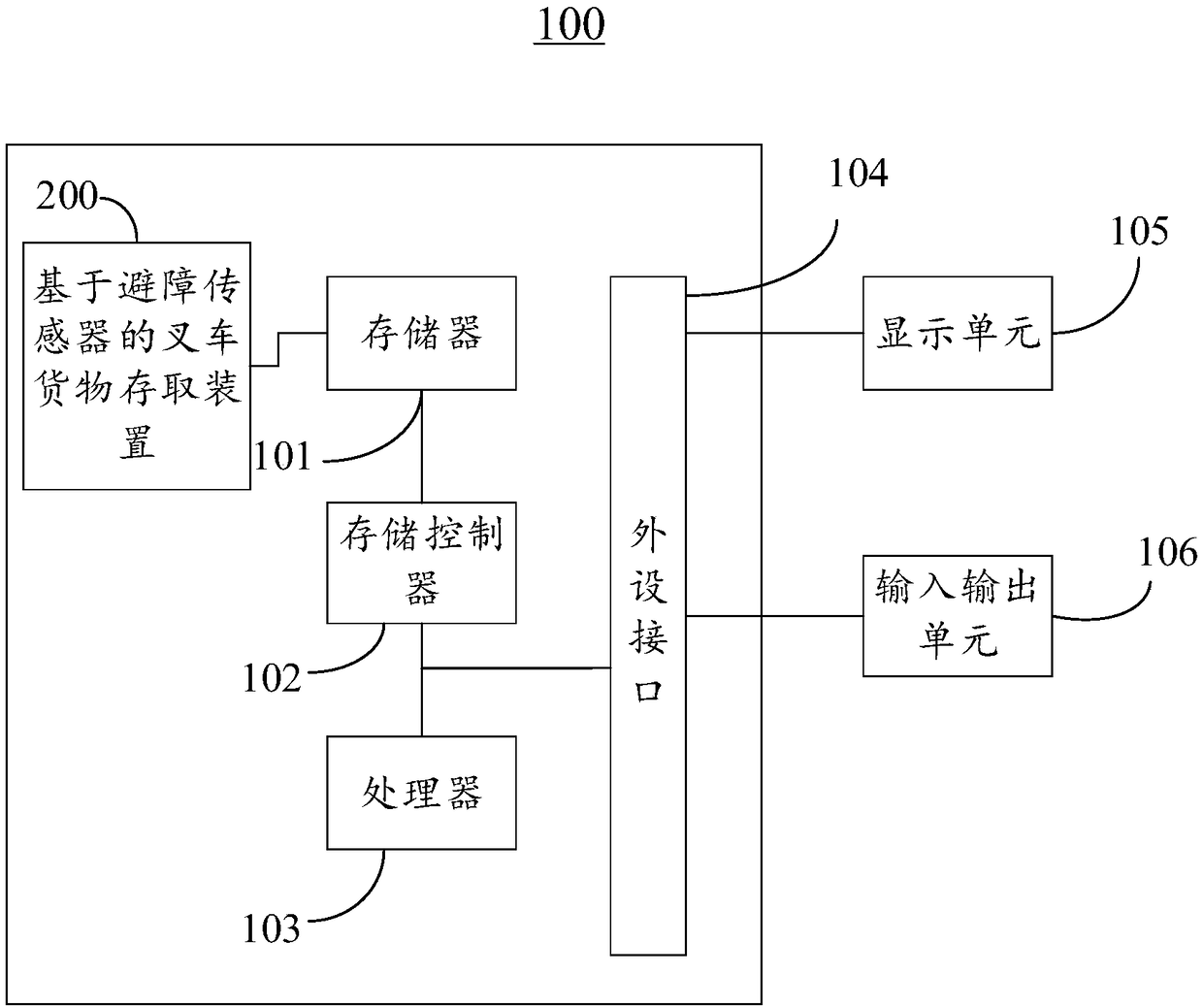

[0067] This embodiment provides a forklift cargo access device 200 based on an obstacle avoidance sensor, please refer to Figure 5 , Figure 5 A schematic diagram of the functional modules of the forklift cargo access device 200 based on the obstacle avoidance sensor provided in this embodiment is shown.

[0068] It should be noted that the obstacle avoidance sensor-based forklift cargo access device 200 provided in this embodiment can be used in the electronic device 100100 to implement the obstacle avoidance sensor-based forklift cargo access method provided in the first embodiment. The basic principles of the forklift cargo access device 200 based on the obstacle avoidance sensor provided in this embodiment and the forklift cargo access method based on the obstacle avoidance sensor provided in the first embodiment are roughly the same. Further details will be given. For details not described in this embodiment, please refer to relevant content in the first embodiment.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com