Single-hole prefabricated hollow slab non-expansion-joint bridge and construction method thereof

A hollow slab and expansion joint technology, used in bridges, bridge parts, bridge construction, etc., can solve the problems of expansion joints prone to various diseases, alarming maintenance costs, atmospheric environment corrosion, etc. Improve the overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

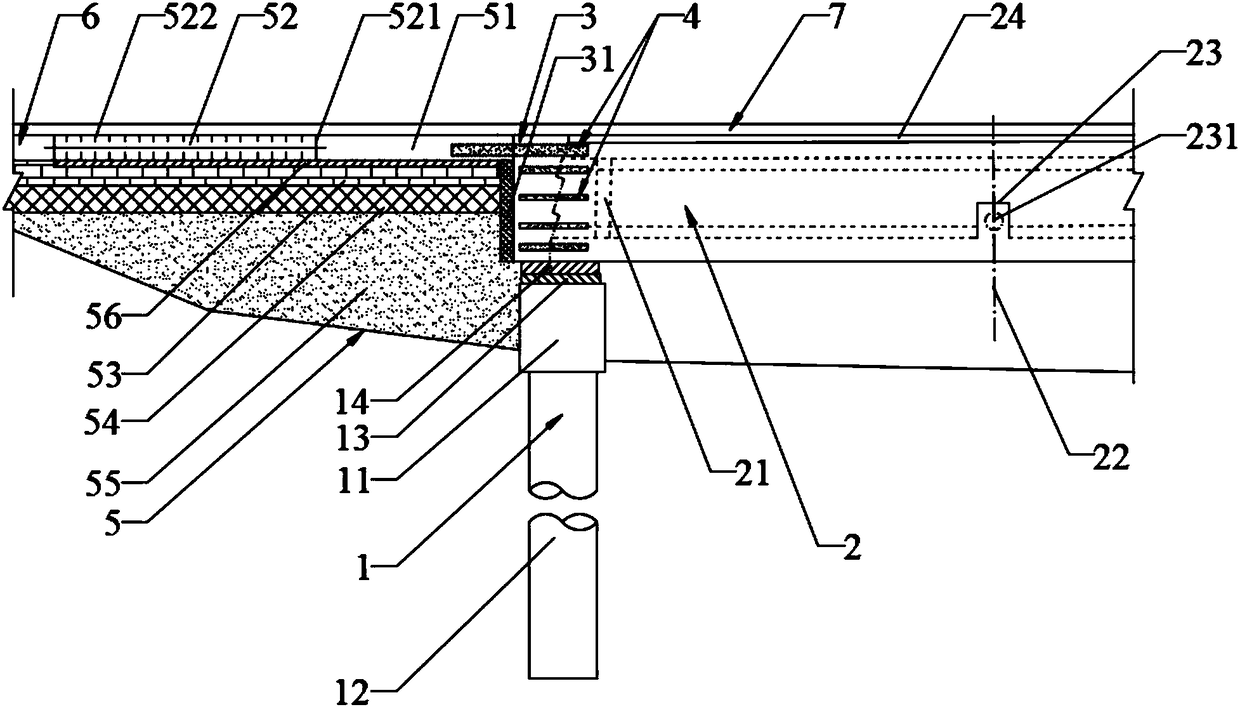

[0070] Please refer to figure 1 As shown, a single-hole prefabricated hollow slab bridge without expansion joints includes an abutment 1, a prefabricated hollow slab 2, an end beam 3 and a steel bar 4 connecting the prefabricated hollow slab 2 and the end beam 3;

[0071] Described abutment 1 comprises platform cap 11 and is arranged on the pile foundation 12 below described platform cap 11, and the upper surface of described platform cap 11 is provided with bearing cushion stone 13, and the upper surface of described bearing cushion stone 13 is provided with There is a rubber cushion 14;

[0072] The prefabricated hollow slabs 2 are arranged side by side on the rubber pad 14 along the transverse bridge direction, the prefabricated hollow slabs 2 are provided with a plug plate 21 covering the cavity of the prefabricated hollow slab 2, and the plug plate 21 is set At the end of the prefabricated hollow slab 2, the prefabricated length of the end of the prefabricated hollow sla...

Embodiment 2

[0079] Please refer to figure 1 As shown, it is the same as other structures of the single-hole prefabricated hollow slab bridge without expansion joints in Embodiment 1, the difference is that the single-hole prefabricated hollow slab bridge without expansion joints also includes a rear wiring system 5, and the back wiring The system 5 comprises a horizontally arranged board 51 and a transition board 52, a base layer located below the board 51 and the transition board 52, and a backfill layer 55; one end of the board 51 and the end beam 3 The other end is connected and the board 51 is arranged on the upper surface of the EPS board 31, the upper surface of the board 51 is at the same height as the upper surface of the end beam 3, and the other end of the board 51 is connected to the upper surface of the EPS board 31. One end of the transition plate 52 is connected, and the other end of the transition plate 52 is connected to the external wiring surface 6. The base layer includ...

Embodiment 3

[0085] Please refer to figure 1 As shown, the present invention also provides a construction method for a single-hole prefabricated hollow slab bridge without expansion joints, comprising the following steps:

[0086]Step 1, carry out the construction of the abutment 1 cap 11, the pile foundation 12 and the support pad stone 13, and lay a rubber cushion 14 on the support pad stone 13 to play the role of a support;

[0087] Step 2. After hoisting all the prefabricated hollow panels 2 into place, build the plug plate 21, cast-in-place end beam 3, and install EPS board 31 on the end beam 3;

[0088] Step 3. After the concrete strength of the cast-in-place end beam 3 reaches the design strength, the hinge joint between the self-compacting concrete cast-in-place prefabricated hollow slabs 2 is used to form the concrete pavement layer 24, and the prestress of the diameter-adding beam 23 is reserved. channel;

[0089] Step 4, the prestressed reinforcement 231 is pierced in the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com