Fabricated steel-wood structure connecting joint

A structural connection and assembly technology, applied in building construction, construction, etc., can solve problems such as long-term occupation of scaffolding, difficulty in bolt insertion, and difficulty in ensuring strength, and achieve reduced maintenance and repair costs, high practical value and economic value. , the effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the drawings.

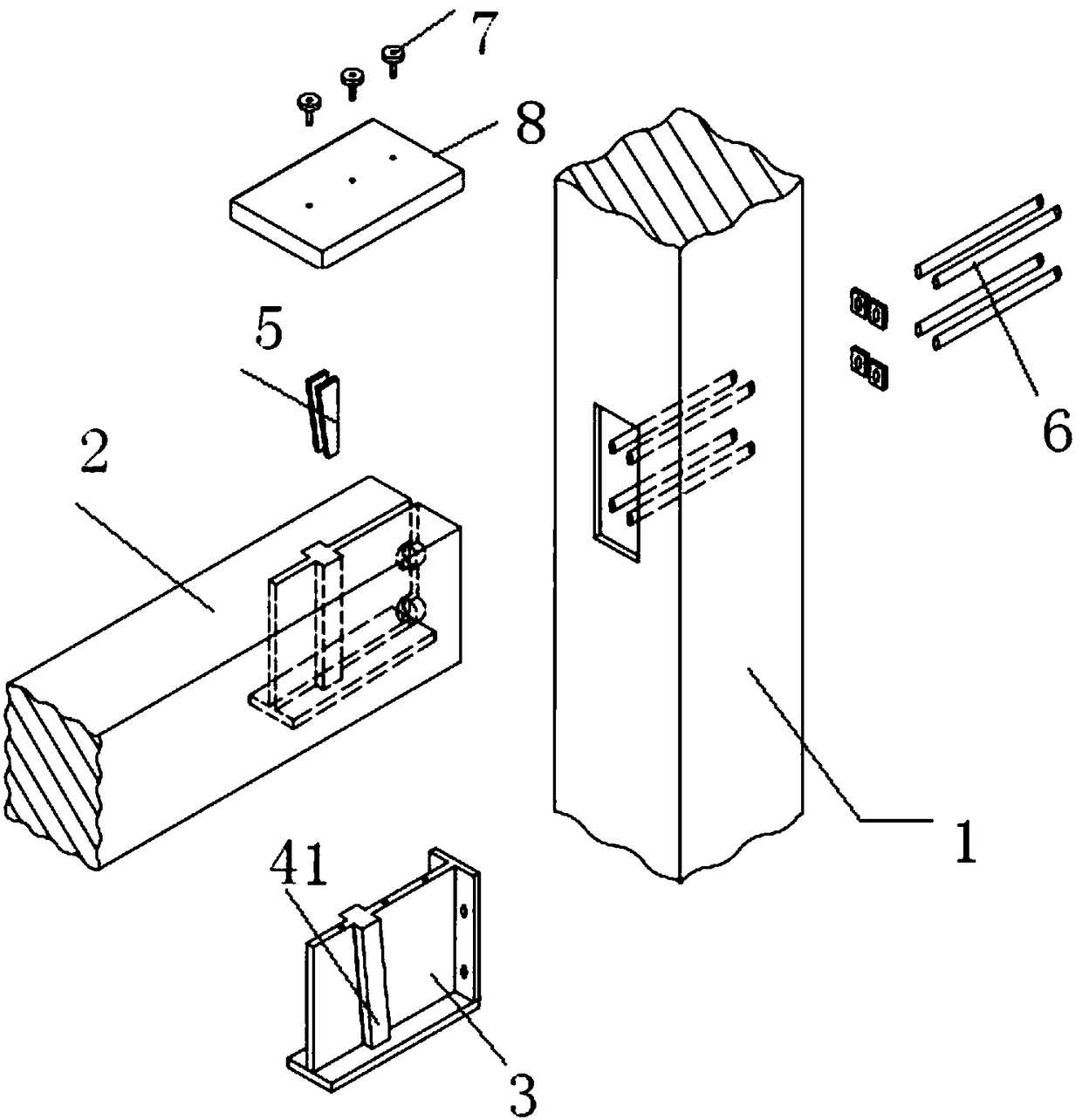

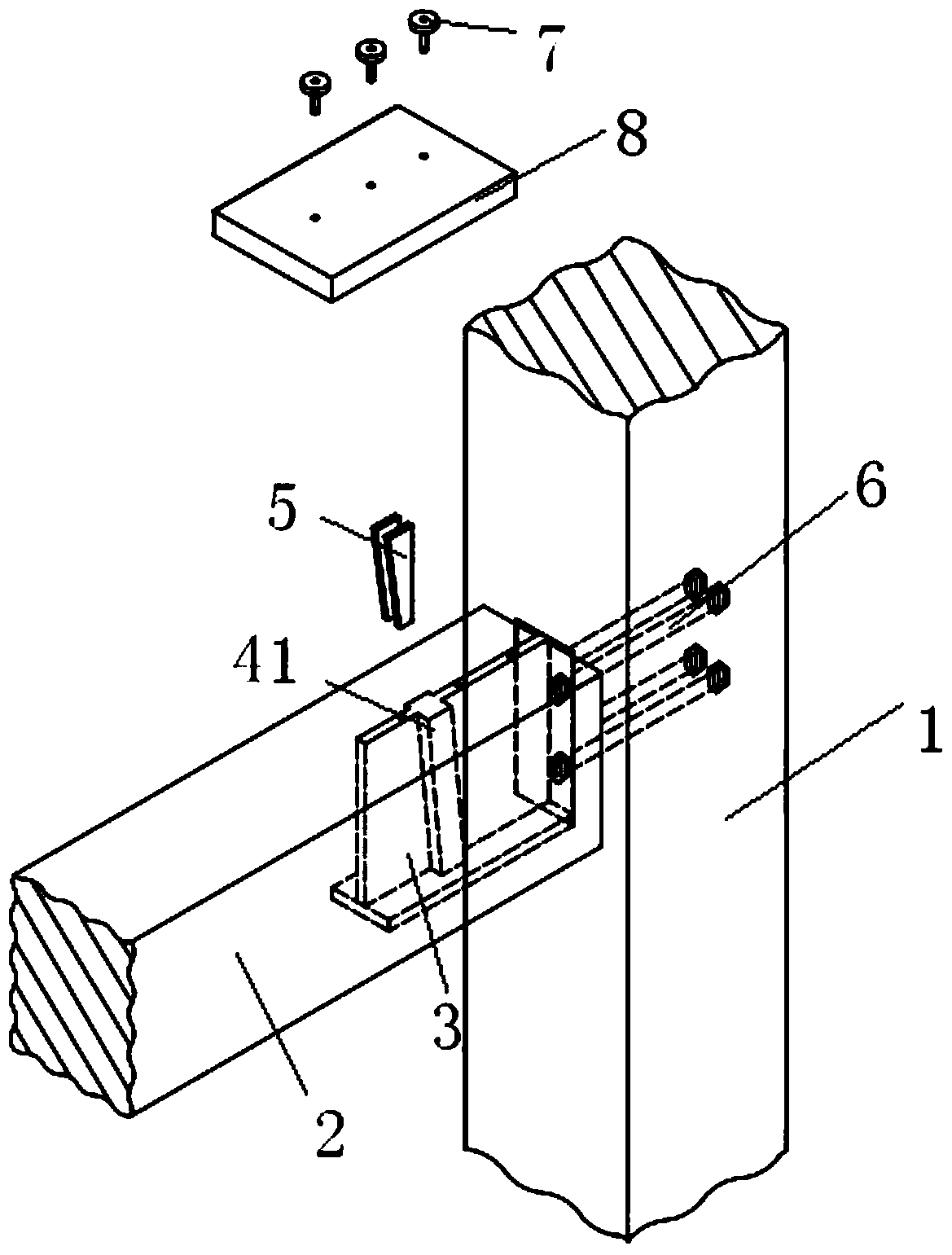

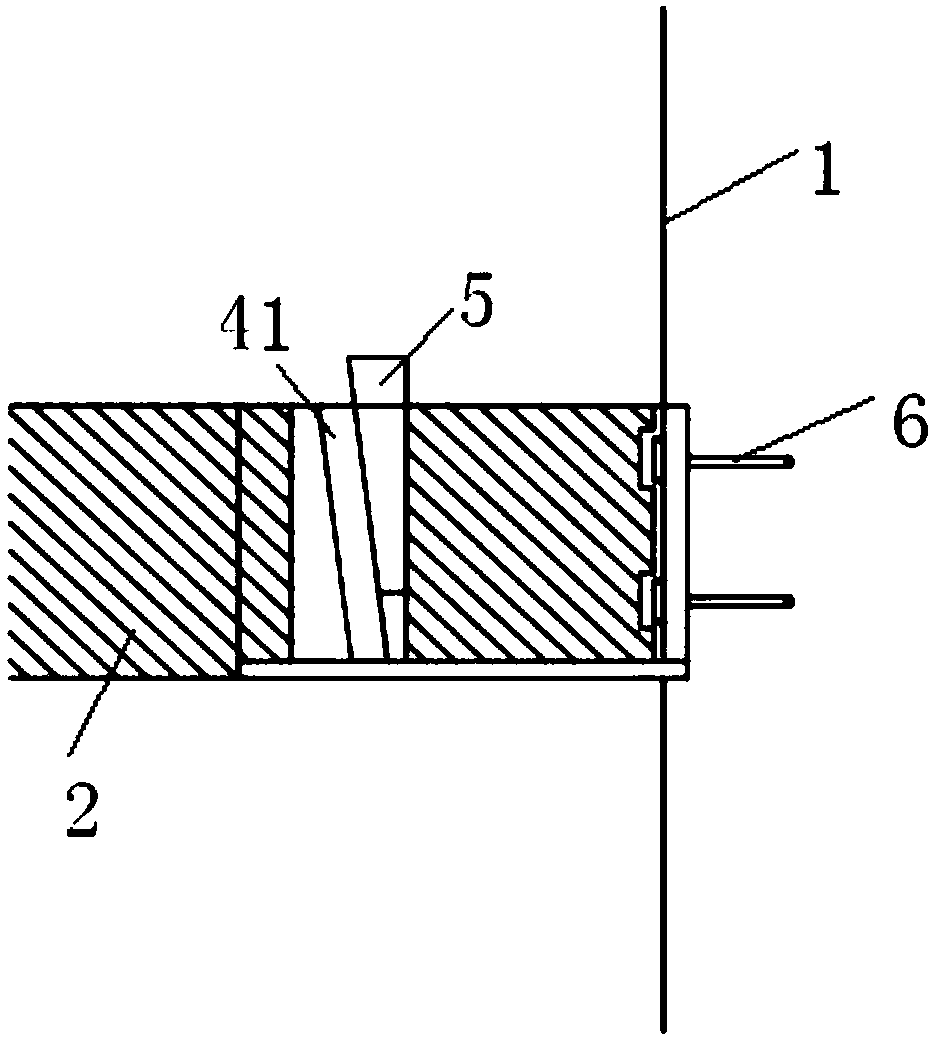

[0029] Reference figure 1 , figure 2 , Figure 5 As shown, a fabricated steel-wood structure connection node includes a column 1 and a beam 2. The end of the beam 2 is inserted into a short inverted T-shaped steel connector 3, a long bolt 6 penetrates through the column 1, and one end of the long bolt 6 is connected The short inverted T-shaped steel connector 3; the web of the short inverted T-shaped steel connector 3 is connected to a cover plate 8 by short bolts 7, and the cover plate 8 is arranged above the beam 2.

[0030] Reference image 3 As shown, the web of the short inverted T-shaped steel connector 3 is provided with a shear connector, and the shear connector is formed by crossing the wooden pin 5 and the stiffening rib 41, and the tibial rib 41 is welded to the short inverted T-shaped steel Both sides of the web of the connecting piece 3; the wooden pins 5 are trapezoidal. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com