Construction method of layer-built grouting of existing structures adjacent to tunnel by advanced same-hole multiple ducts

A technology with existing structures and construction methods, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as slow drilling of grouting holes, poor matching of oil grouting technology and equipment, and influence on urban subway construction, etc., to avoid The effect of the collapse accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] 1. Grouting range and hole layout design

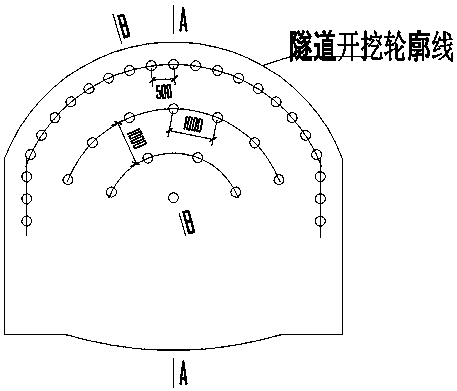

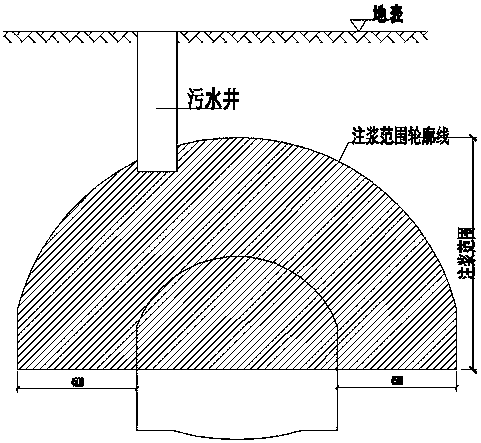

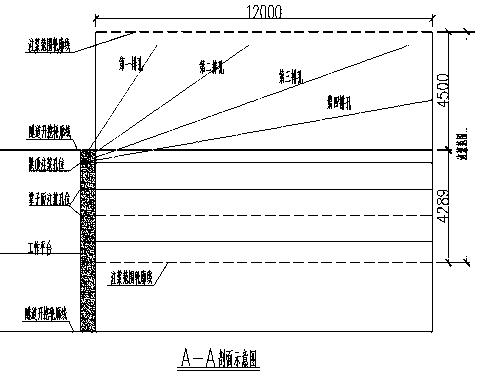

[0028] The grouting range of the tunnel section is 4.5m outside the tunnel excavation contour. The grouting section is 12.0m, and the grouting wall is set before the grouting hole.

[0029] Hole spacing: the grouting holes outside the tunnel arch line are arranged within 500mm of the tunnel excavation contour line, the distance between the conduits along the arch line is 0.5m; the distance between the holes on the tunnel face is 1.0m.

[0030] The number of grouting holes, drilling angle and length of installation conduit: a total of 35 points are arranged in the grouting section, and a total of 23 points are arranged for grouting outside the arch line. Further, each of the 23 points for grouting outside the arch line There are 4 rows of inclined holes and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com