Auto parts cleaning device

A technology for auto parts and cleaning devices, which is applied in the direction of cleaning hollow objects, dry gas arrangement, cleaning methods and utensils, etc. It can solve the problems such as inconvenient cleaning of the inner wall of tubular parts, achieve good cleaning effect and speed up the reset speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following is further described in detail through specific implementation methods:

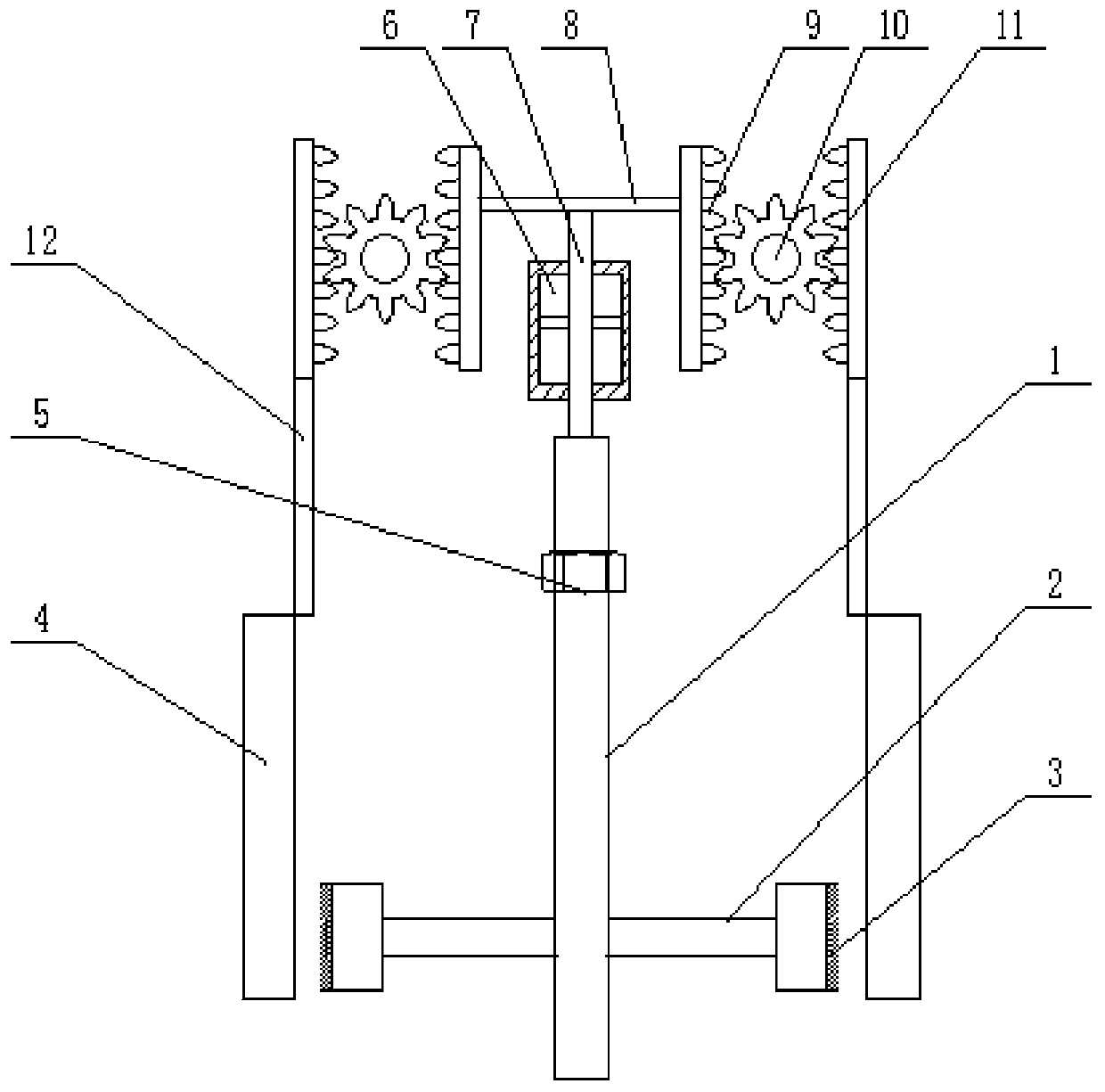

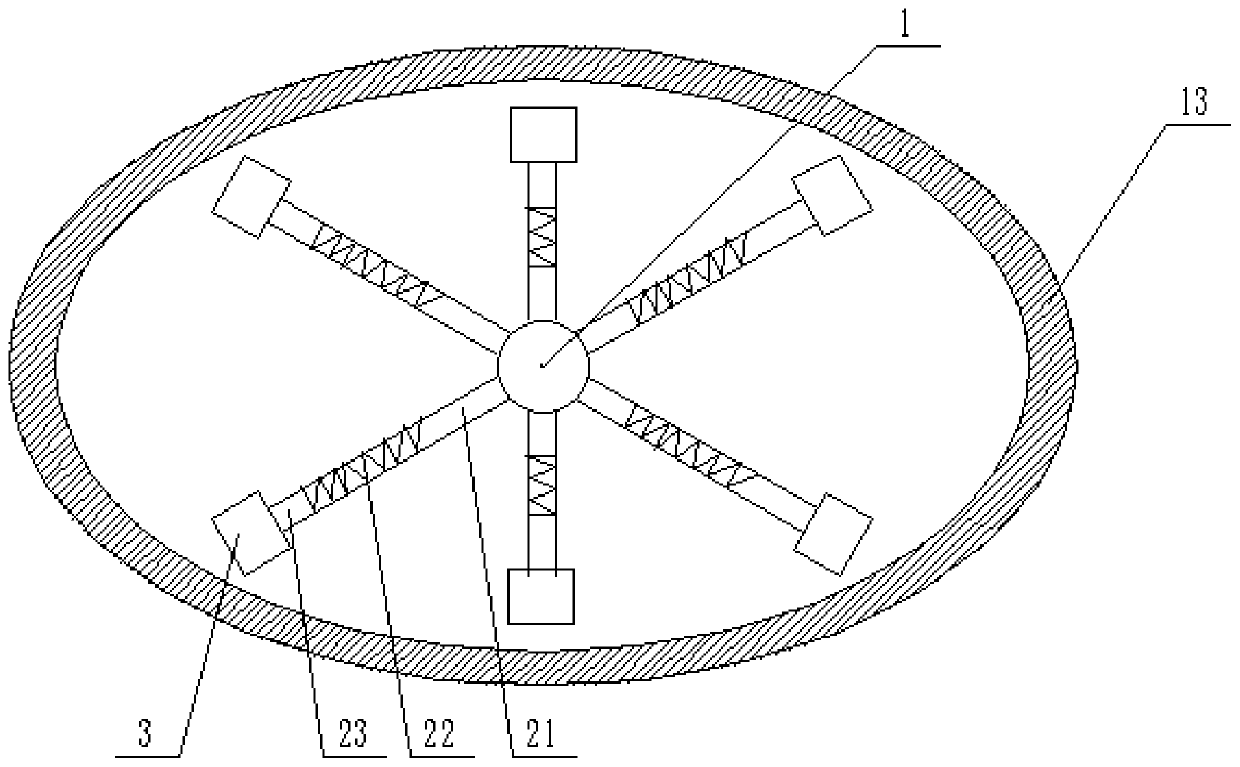

[0020] The reference signs in the drawings of the description include: rotating shaft 1, cleaning rod 2, cleaning brush 3, splint 4, nut 5, piston barrel 6, piston rod 7, connecting rod 8, first rack 9, first gear 10, Second rack 11, push rod 12, parts 13, first horizontal section 21, spring section 22, second horizontal section 23.

[0021] like figure 1 As shown, the auto parts cleaning device includes a frame, which is provided with a conveying part, a clamping part, and a cleaning part. The bottom of the frame is also provided with a collection box below the clamping part. Slanted filter. The clamping part includes splints 4 arranged at both ends of the frame, and the two splints 4 are connected with magnets.

[0022] The cleaning part includes a rotating shaft 1 arranged in the middle of the two splints 4. The rotating shaft 1 includes a spline section and a thread section be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com