Tool turret rotating structure and tool turret rotating method

A technology of rotating structure and turret, applied in the direction of tool holder, etc., can solve the problems of low rotation accuracy, loose tool handle, high cost, etc., to prevent the turret from swinging, prevent the turret from moving up and down, and achieve good stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

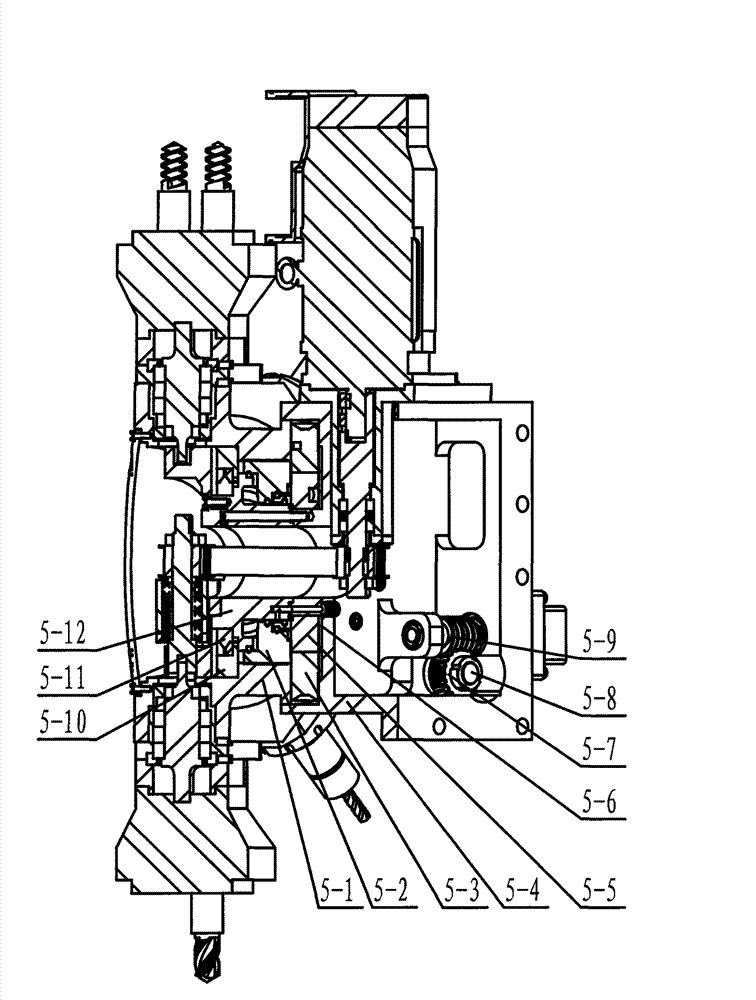

[0011] Embodiment 1: see attached figure 1 . A turret rotation structure, which includes a turret 5-1, the rotation of the turret 5-1 adopts a three-plate clutch structure and consists of an indexing toothed plate A5-3, an indexing toothed plate B5-2, an indexing tooth Disk C5-5 and friction plate 5-6 are composed of indexing toothed plate A5-3 fastened on turret 5-1, indexing toothed plate C5-5 is fastened on base 5-4, and indexing toothed plate B5 -2 can be used for piston movement, the teeth of the indexing toothed plate A5-3 and the indexing toothed plate C5-5 are aligned, and the indexing toothed plate B5-2 is opposite to the indexing toothed plate A5-3 and the indexing toothed plate C5- 5. Engage and lock the teeth. The servo motor and the worm 5-9 drive the worm gear 5-7 to rotate through the worm. The worm gear is installed on the cylindrical helical gear shaft 5-8. Mesh with cylindrical helical gear shaft 5-8 to drive turret 5-1 to rotate together; friction plate 5-...

Embodiment 2

[0012] Embodiment 2: On the basis of Embodiment 1, the rotation method of the turret rotation structure, the indexing toothed plate A is fastened on the turret, the indexing toothed plate C is fastened on the base, and the indexing toothed plate B can be used as Piston movement, indexing toothed disc A and indexing toothed disc C are aligned and placed, indexing toothed disc B engages and locks the indexing toothed disc A and indexing toothed disc C, when the turret needs to rotate , using oil pressure to disengage the indexing tooth plate B, the servo motor is connected to the worm, and the worm is controlled to rotate at the same speed to drive the worm wheel. The worm wheel is installed on the cylindrical helical gear shaft, and the outer circular helical teeth of the indexing tooth plate A The meshing of cylindrical helical gear shaft and gear drives the turret to rotate together to realize the function of turret rotation; during the rotation process, the turret can rotate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com