Paper cutter

A technology of a paper cutter and a paper pressing mechanism, which is applied in the direction of metal processing and the like, can solve the problems of easy cutting hands, complicated structure, and complicated structure of paper cutter loader, etc., and achieves the effect of simple structure and improved portability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

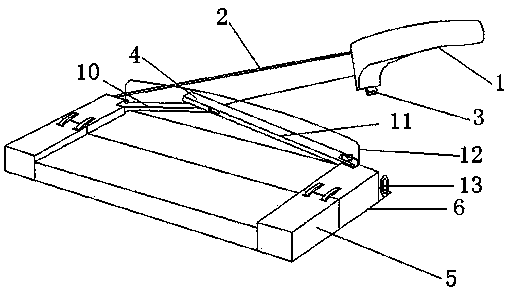

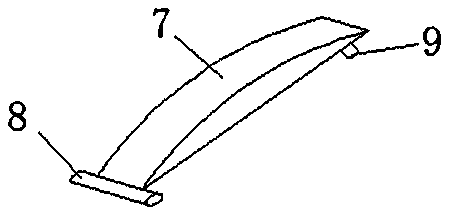

[0028] Such as figure 1 As shown, a novel paper cutter of the present invention includes a handle 1, a guillotine 2, a lever paper pressing mechanism 4 and a base, the guillotine 2 is installed on one side of the base, and the lever paper pressing mechanism 4 is arranged on the same side as the guillotine 2 Above the base paper entrance, the lever paper pressing mechanism 4 includes a left lever 10 and a right lever 11, one end of the left lever 10 is arranged on the left side of the base, and one end of the right lever 11 is arranged on the right side of the base. Side, the end of the left lever 10 is arranged on the bottom of the right lever 11 end, and the bottom of the right lever 11 is provided with a groove for accommodating the left lever 10. The base comprises two parts, a left half 5 and a right half 6, and the left half 5 and the right half 6 are detachably connected. The bottom of the end of the right lever 11 is provided with an elongated through groove, and the e...

Embodiment 2

[0030] As a further innovation of the present invention, the technical feature of the difference between this embodiment and Embodiment 1 is that a hand guard 12 is provided between the guillotine 2 and the lever paper pressing mechanism 4 in order to prevent accidental cutting of human hands when cutting paper. . Further preferably, the finger guard 12 is made of transparent organic glass material.

Embodiment 3

[0032] As a further innovation of the present invention, the difference between this embodiment and the above two embodiments is that it also includes a safety lock, and the safety lock is used to prevent the paper cutter from being mishandled by children when it is not in use. It includes a locking part 3 arranged at the bottom of the tail end of the handle 1 , and a buckle 13 is provided on the side of the base corresponding to the locking part 3 at the bottom of the handle 1 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap