A rotary press device for a printing machine

A rotary press technology for printing machines, applied in metal processing, etc., can solve the problems of low paper press efficiency, low paper press efficiency, and unsatisfactory paper flatness, and achieve the effect of improving paper press efficiency and ensuring flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

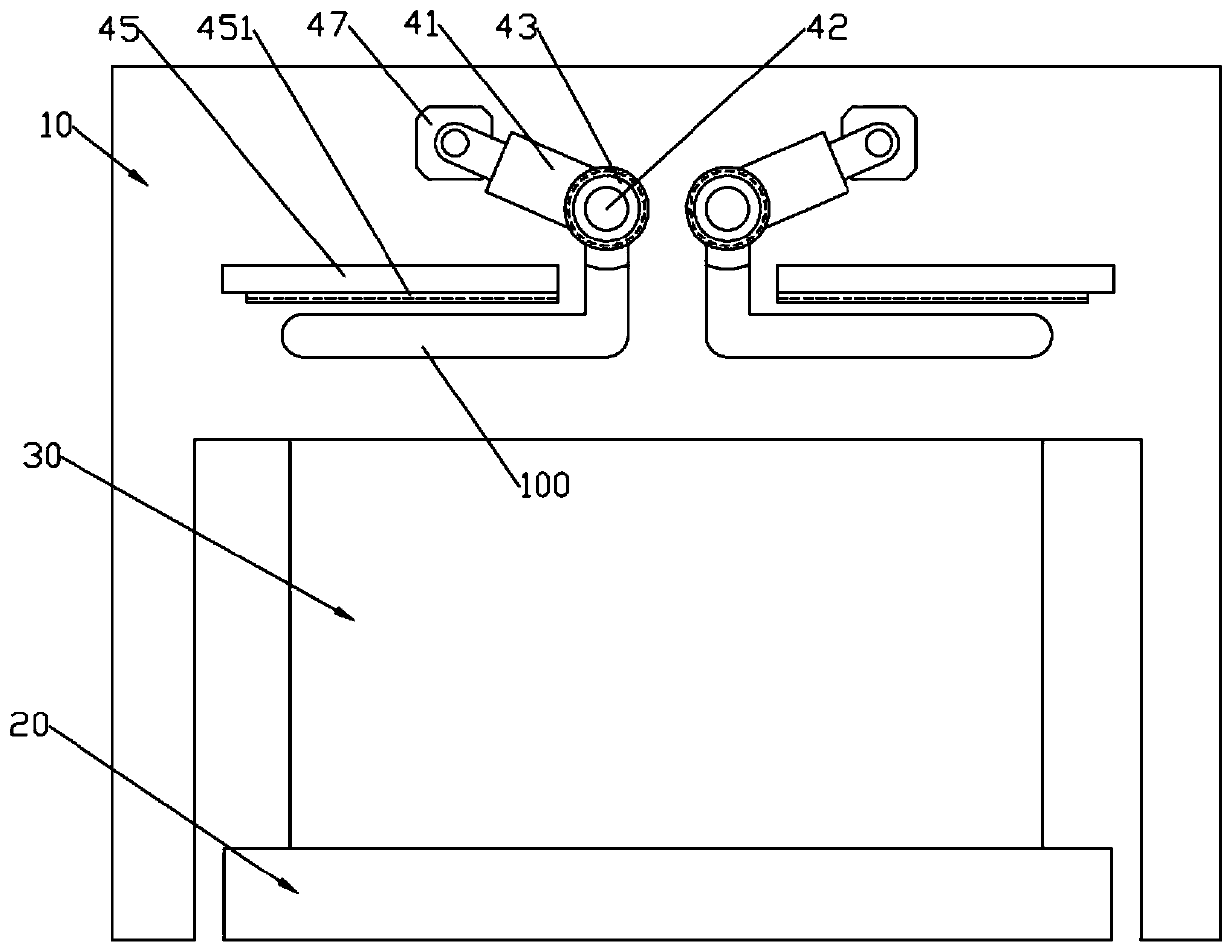

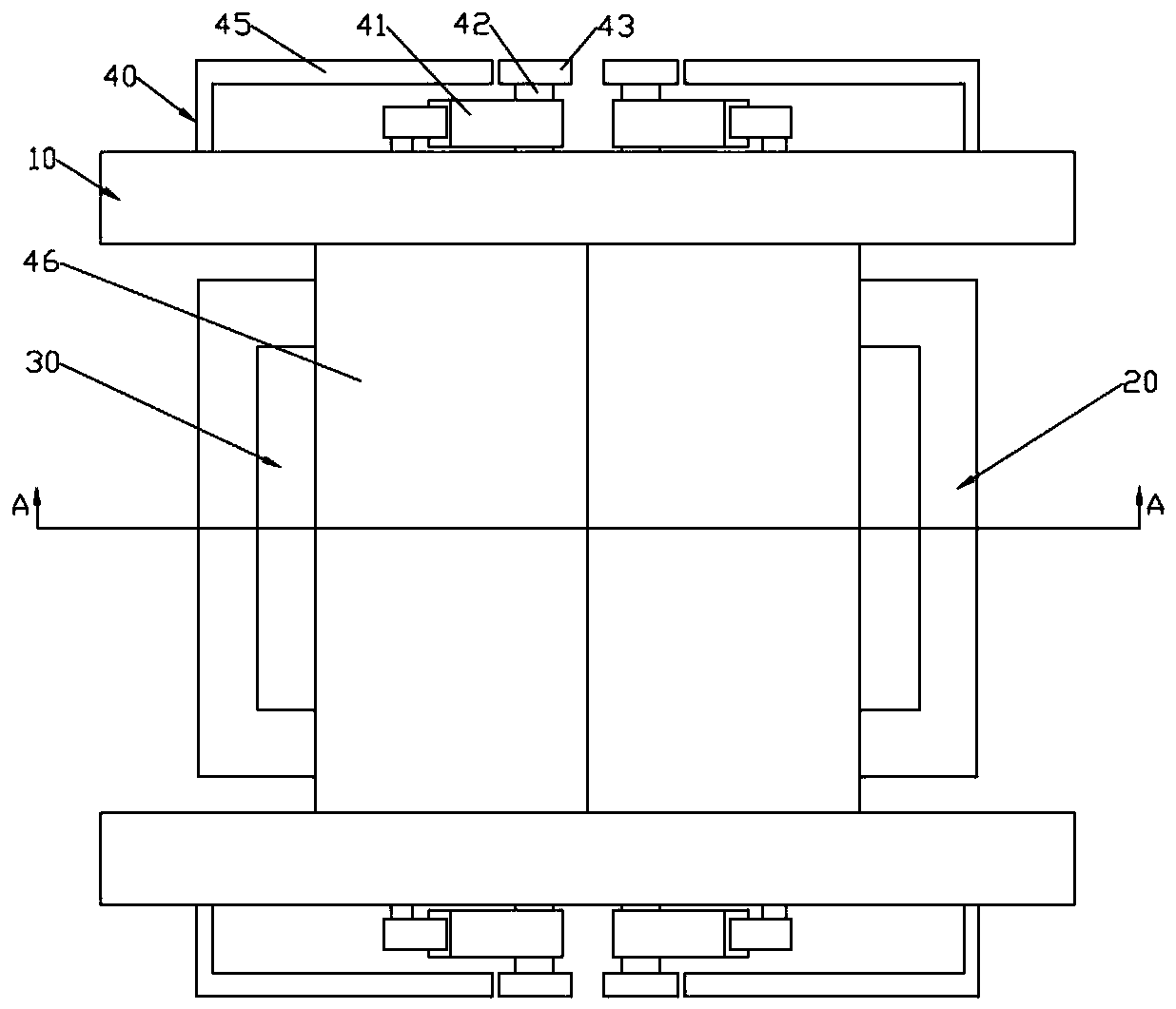

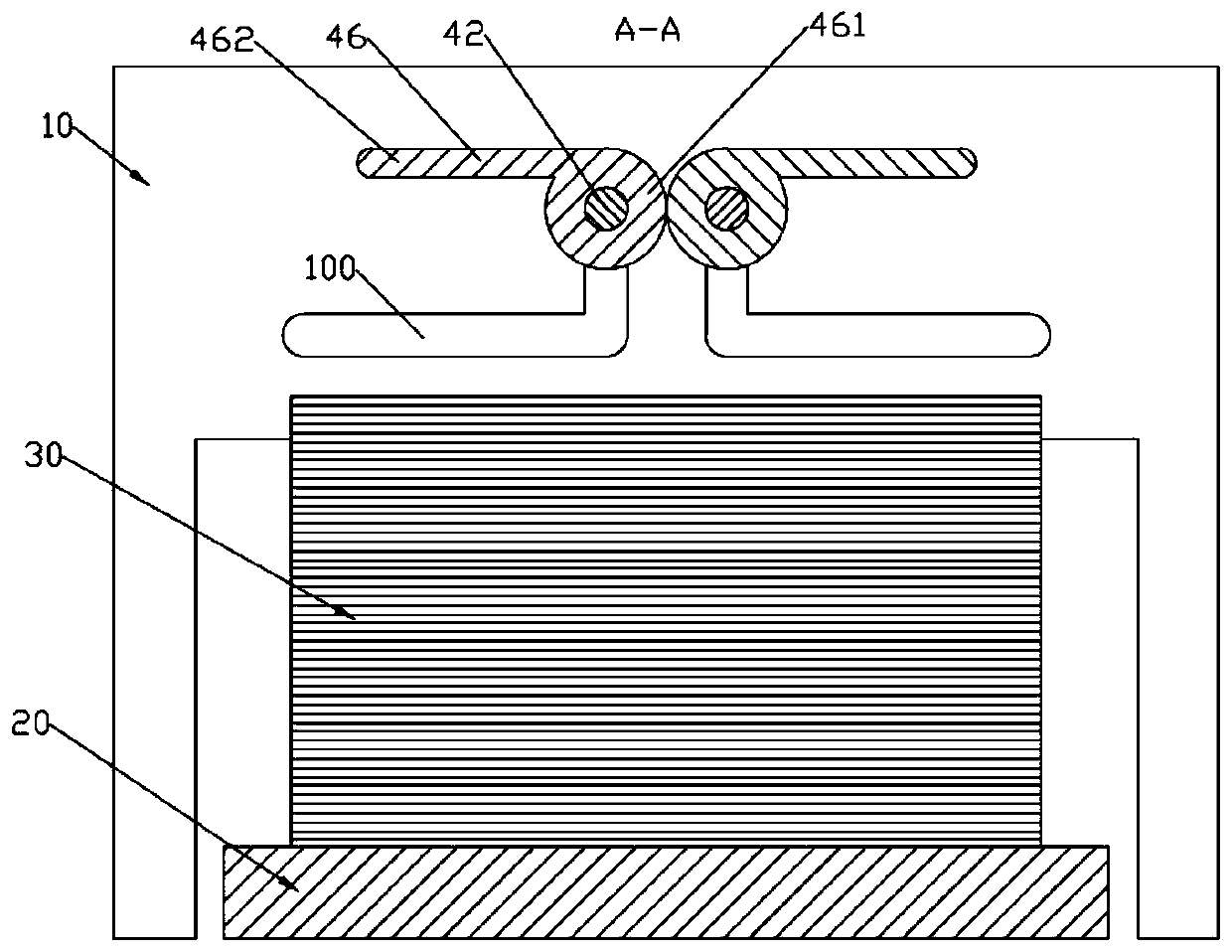

[0013] Such as Figure 1 ~ Figure 3 As shown, a rotary press device for a printing machine includes a frame 10, a paper placement table 20, a paper pile 30 and a rotary press device 40; the frame 10 includes a pair of support plates symmetrically arranged front and back; the paper placement work The table 20 is arranged between a pair of support plates and the stack of paper 30 is placed on the paper placement workbench 20; the rotary paper pressing device 40 includes a pair of pressing blocks 46 symmetrically arranged left and right; the pair of pressing blocks 46 includes cylindrical pressing columns 461 and pressing plate 462; the pressing plate 462 is formed on the outer cylindrical surface of the pressing column 461 and the outer end surface of the pressing plate 462 is arranged tangentially with the outer cylindrical surface of the pressing column 461; The L-shaped guide groove 100; a pair of front and rear symmetrical guide grooves 100 is slidingly provided with the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com