Box cover feeding station on box loading production line

A technology of production line and box cover, which is applied in the direction of packaging, etc., can solve the problems that the box cover cannot be placed on the box body accurately and quickly, affects the gland, and has many assembly stations, so as to achieve a standardized assembly process, save labor costs, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

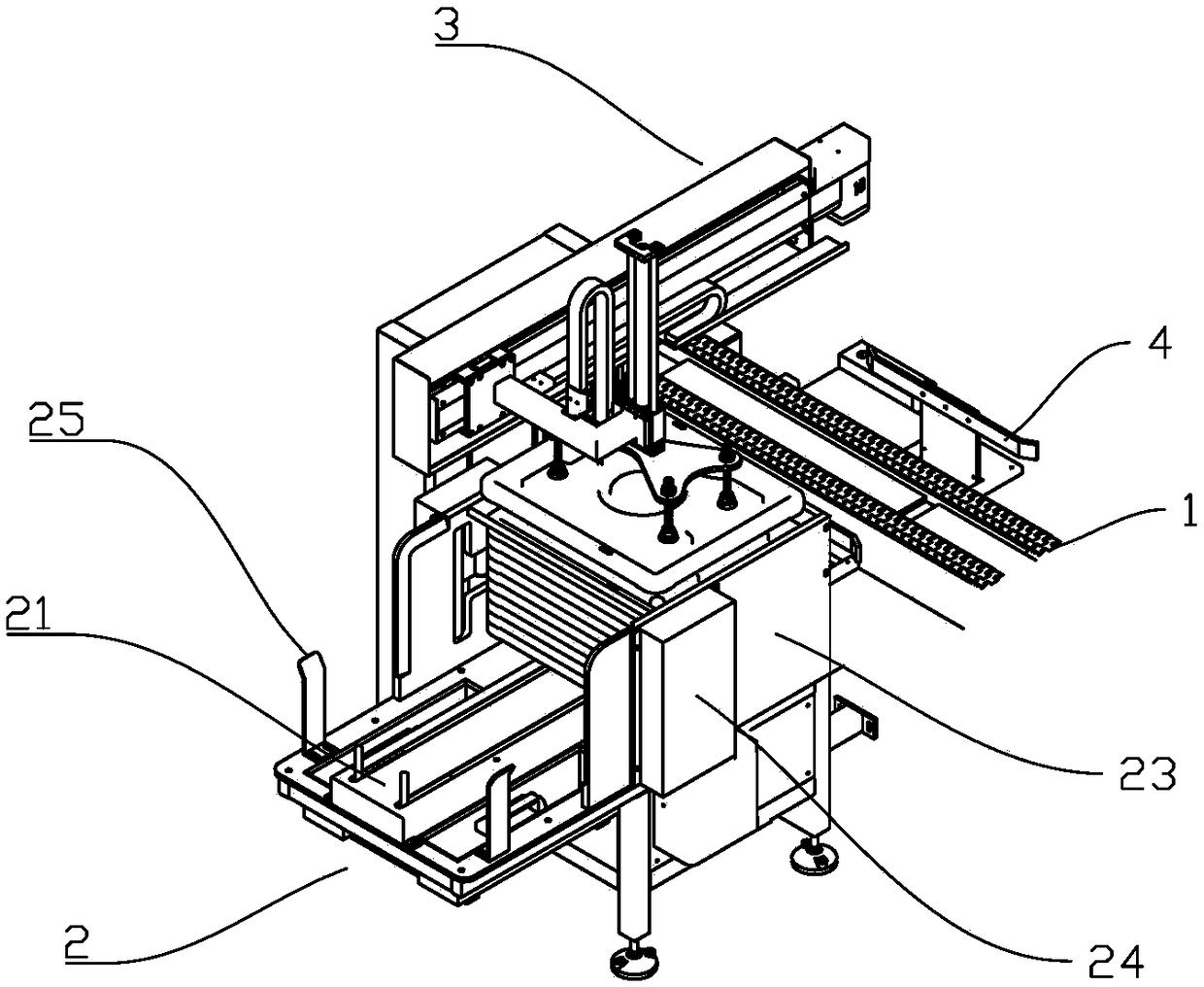

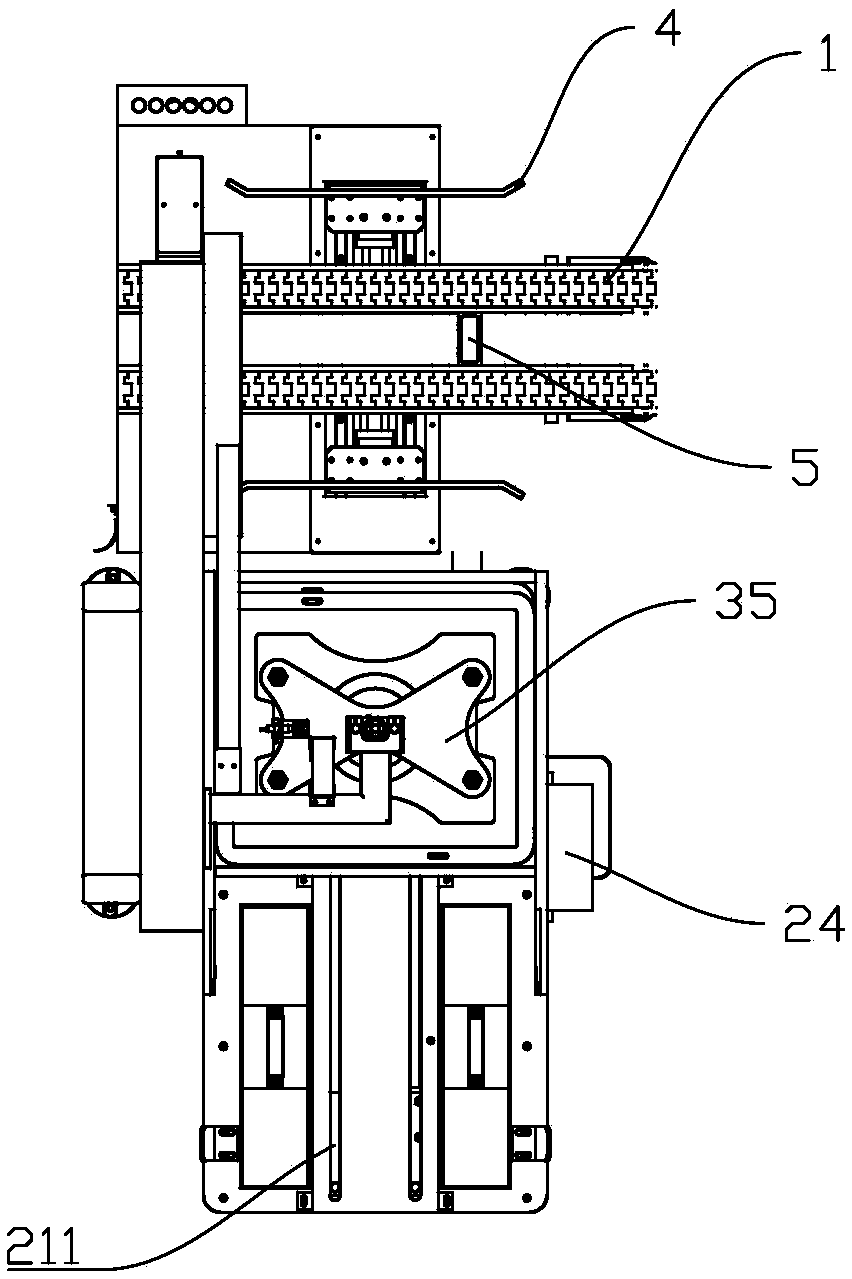

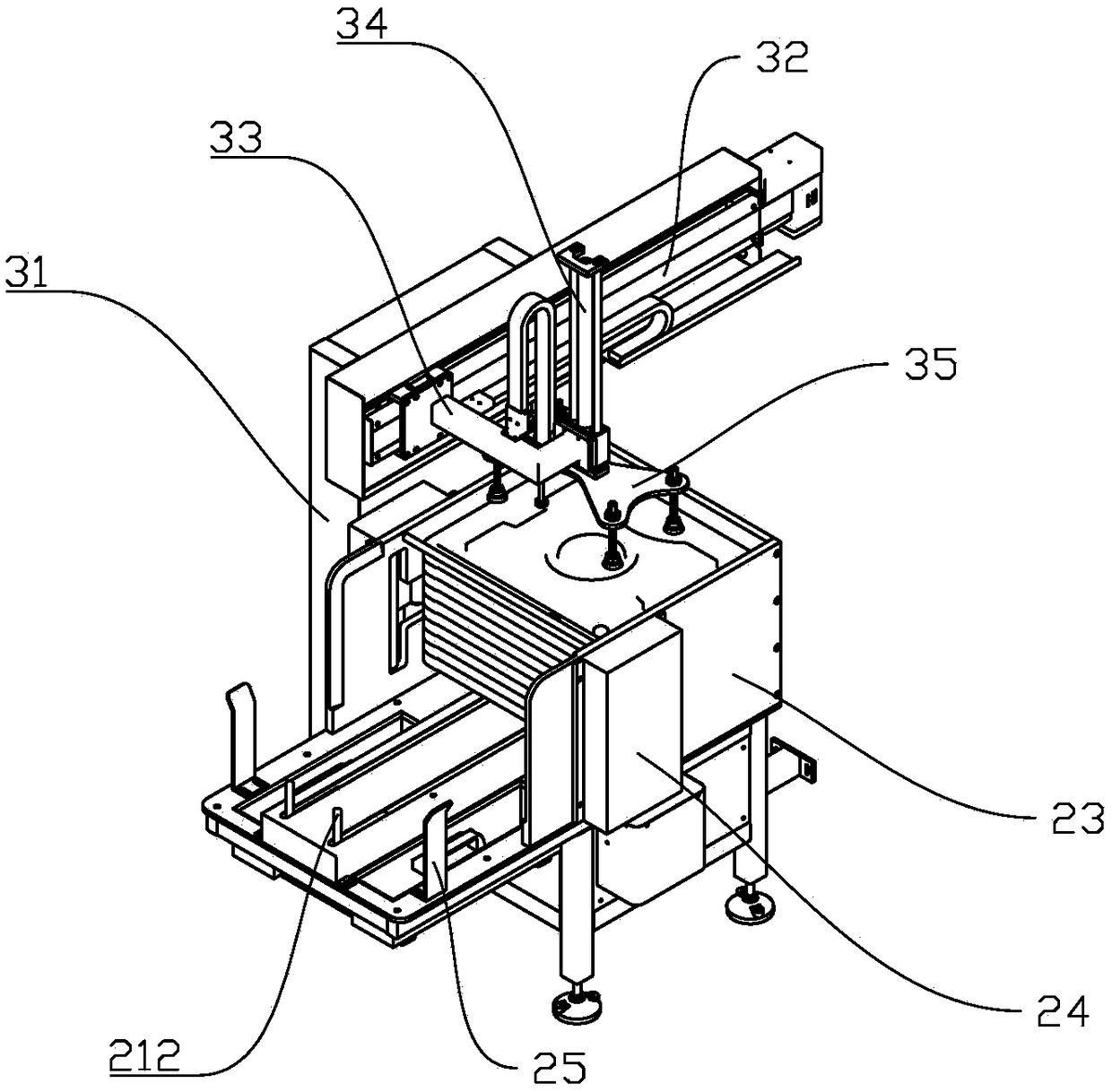

[0024] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-6 :

[0025] A box cover station on a box packing production line, including a crawler belt 1 for transporting a box body, a box cover storage platform 2 and a manipulator 3, the box cover storage platform 2 is located on one side of the crawler belt 1, and the lower part of the box cover storage platform 2 A power-driven box cover pusher 21 is provided, and the rear end of the box cover storage platform 2 is provided with a positioning plate 22 perpendicular to the box cover storage platform 2, and there are side plates vertically connected with the positioning plate 22 on both sides of the box cover storage platform 2 23. A bracket 31 is arranged outside one of the side plates; the manipulator 3 includes a horizontal slide rail 32 fixed on the top of the bracket 31 and perpendicular to the crawler belt. A lifting block 34 that can sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com