Connecting structure for concealed-seam aluminum plate of curtain wall

A technology for connecting structures and curtain walls, applied in the direction of walls, building components, building structures, etc., can solve the problems of affecting the facade effect, hidden dangers of water seepage, ash hanging on glue joints, etc., to improve the quality of appearance, good drainage function, The effect of eliminating the influence of temperature deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

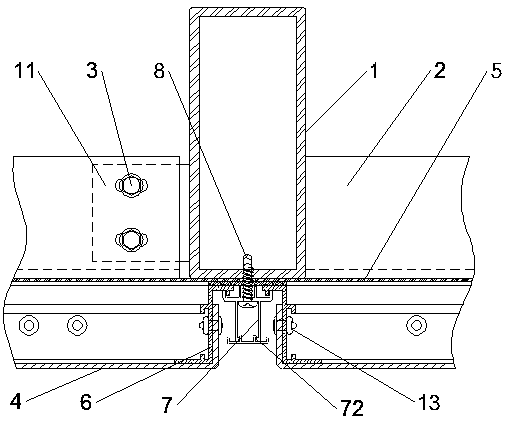

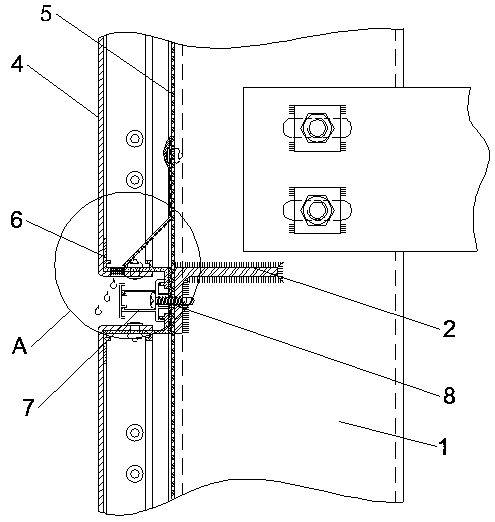

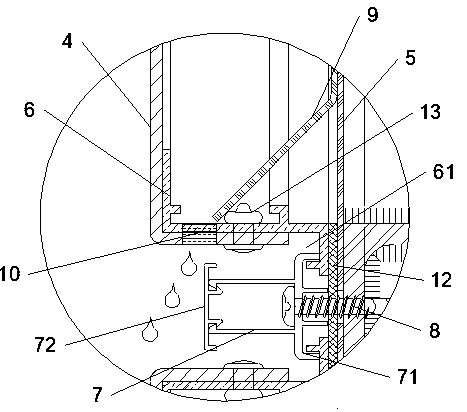

[0015] Such as figure 1 , figure 2 and image 3 The curtain wall hidden seam aluminum plate connection structure shown includes a curtain wall column 1 and beams 2 on both sides of the curtain wall column 1. An angle steel 11 is fixed on one side of the curtain wall column 1, and the beam 2 is connected to the angle steel 11 by bolts 3. The other side of the curtain wall column 1 is welded with the beam 2, which can eliminate the influence of temperature deformation and increase the in-plane deformation capacity of the curtain wall. The outer side of the curtain wall column 1 and the beam 2 is provided with a 3mm thick aluminum plate 4, and the inner side of the aluminum plate 4 is provided with There is a 1.5mm thick galvanized waterproof steel plate 5 close to the outside of the curtain wall column 1 and the beam 2, and an aluminum alloy sub-frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com