Composite gas bearing with surface texture and surface texture design method

A surface texture, gas bearing technology, applied in the direction of rotating bearings, bearings, bearing components, etc., can solve problems such as insufficient bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

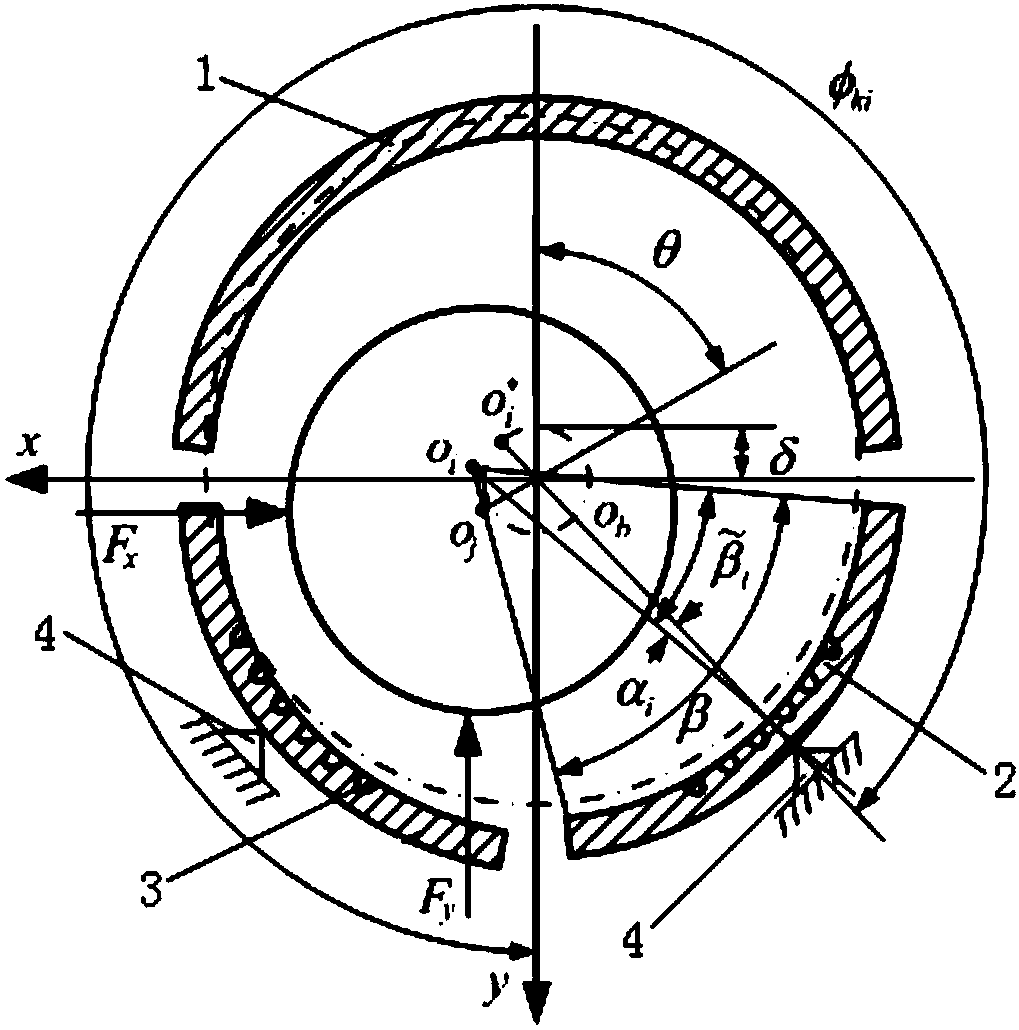

Embodiment 1

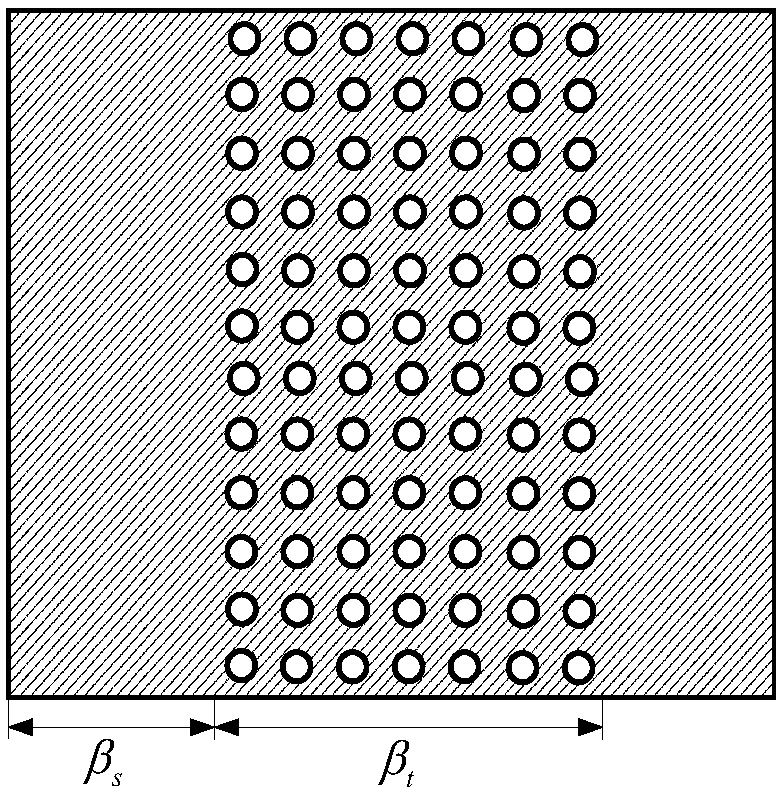

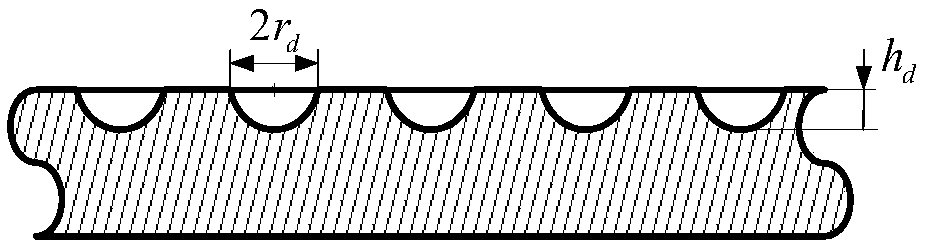

[0098] Such as figure 2 and image 3 As shown, the surface texture 3 is in the form of pits, and the shape of the pits is spherical. The axial surface texture rate of the spherical pit (the axial width of the surface texture area b t The ratio to the width b of the tilting pad 2) t is 100%; the circumferential surface texture rate (circumferential angle β of the surface textured area t The ratio of the wrapping angle β to the tilting pad block 2) s takes a value between 10% and 50%; the ratio of the surface texture initiation angle of the spherical pit (the angle β sThe ratio of the wrapping angle β to the tilting pad 2)k takes a value between 0% and 50%; the depth of the spherical pit h d Values between 10 and 100 microns; radius r of spherical dimples d Take values between 50 and 200 microns.

Embodiment 2

[0100] Such as Figure 4 and Figure 5 As shown, the surface texture 3 is in the form of pits, and the shape of the pits is cylindrical. Axial surface texture rate of cylindrical pits (axial width of surface textured area b t The ratio to the width b of the tilting pad 2) t is 100%; the circumferential surface texture rate (circumferential angle β of the surface textured area t The ratio of the wrapping angle β to the tilting pad block 2) s takes a value between 10% and 50%; the surface texture starting angle ratio of the cylindrical pit (the angle β between the surface texture and the starting edge of the tilting pad s The ratio of the wrapping angle β to the tilting pad 2)k is between 0% and 50%; the depth h of the cylindrical pit d Values between 10 and 100 microns; radius r of the cylindrical pit d Take values between 50 and 200 microns.

Embodiment 3

[0102] Such as Figure 6 and Figure 7 As shown, the surface texture 3 is in the form of pits, and the shape of the pits is square. The axial surface texture rate of the square pit (the axial width of the surface texture area b t The ratio to the width b of the tilting pad 2) t is 100%; the circumferential surface texture rate (circumferential angle β of the surface textured area t The ratio of the wrapping angle β to the tilting pad block 2) s takes a value between 10% and 50%; the ratio of the starting angle of the surface texture of the square pit (the angle β s The ratio of the wrapping angle β to the tiltable tile block 2)k takes a value between 0% and 50%; the depth h of the square pit d Values between 10 and 100 microns; radius r of the square pit d Take values between 50 and 200 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com