Automatic demagnetization device for atomic clock-shaped magnetic shield

A magnetic shielding and atomic clock technology, applied to magnetic objects, circuits, electrical components, etc., can solve the problems of inability to obtain demagnetization results, increased demagnetization current, and the need for repeated demagnetization, so as to achieve safe and reliable demagnetization process, smooth and delicate current changes, Good demagnetization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

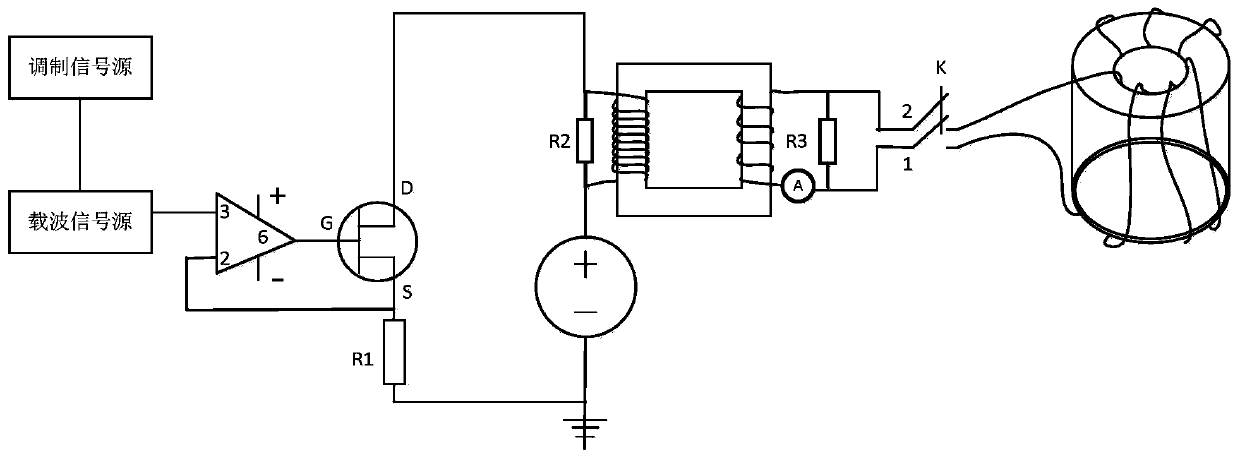

[0016] exist figure 1 Among them, the automatic demagnetization device of the atomic clock cylindrical magnetic shield of the present embodiment is composed of a modulation signal source, a carrier signal source, an operational amplifier, a field effect tube, a resistor R1, a DC power supply, a transformer, a knife switch K, a resistor R2, a resistor R3, and an ammeter A. The demagnetization coil is connected.

[0017] The output end of the modulation signal source is connected to the modulation end of the carrier signal source. The modulation signal source outputs a sinusoidal signal with a frequency of 0.005Hz, which is used to modulate the amplitude of the carrier signal. The carrier signal source outputs a modulated sinusoidal signal with a frequency of 50Hz. The carrier signal source The output terminal of the operational amplifier is connected to the 3-pin of the operational amplifier, the 2-pin of the operational amplifier is connected to the S terminal of the FET and g...

Embodiment 2

[0019] In this embodiment, the output end of the modulation signal source is connected to the modulation end of the carrier signal source, and the modulation signal source outputs a sinusoidal signal with a frequency of 0.002 Hz, which is used to modulate the amplitude of the carrier signal source, and the modulated frequency of the carrier signal source is 20 Hz. Sinusoidal signal. Other components and the connection relationship of the components are the same as in Embodiment 1.

Embodiment 3

[0021] In this embodiment, the output end of the modulation signal source is connected to the modulation end of the carrier signal source. The modulation signal source outputs a sinusoidal signal with a frequency of 0.02 Hz, which is used to modulate the amplitude of the carrier signal source. The modulated frequency of the carrier signal source is 200 Hz. Sinusoidal signal. Other components and the connection relationship of the components are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com