Segmented plug-in type heating rod

A heating rod and plug-in technology, applied in the shape of heating elements, ohmic resistance heating, ohmic resistance heating parts, etc., can solve problems such as increased maintenance and worse parts costs, equipment failure to work normally, process loss, etc., to achieve The effect of reducing the requirements of the installation environment, facilitating control, and reducing maintenance and use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

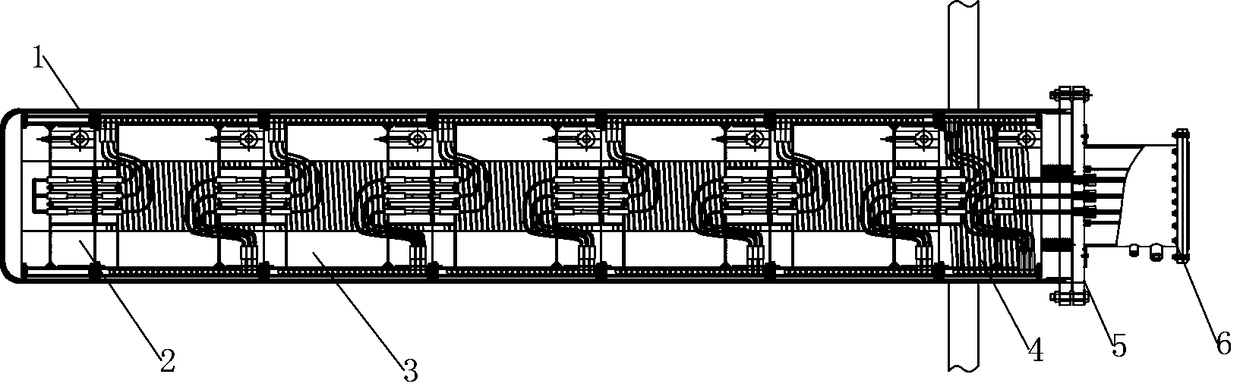

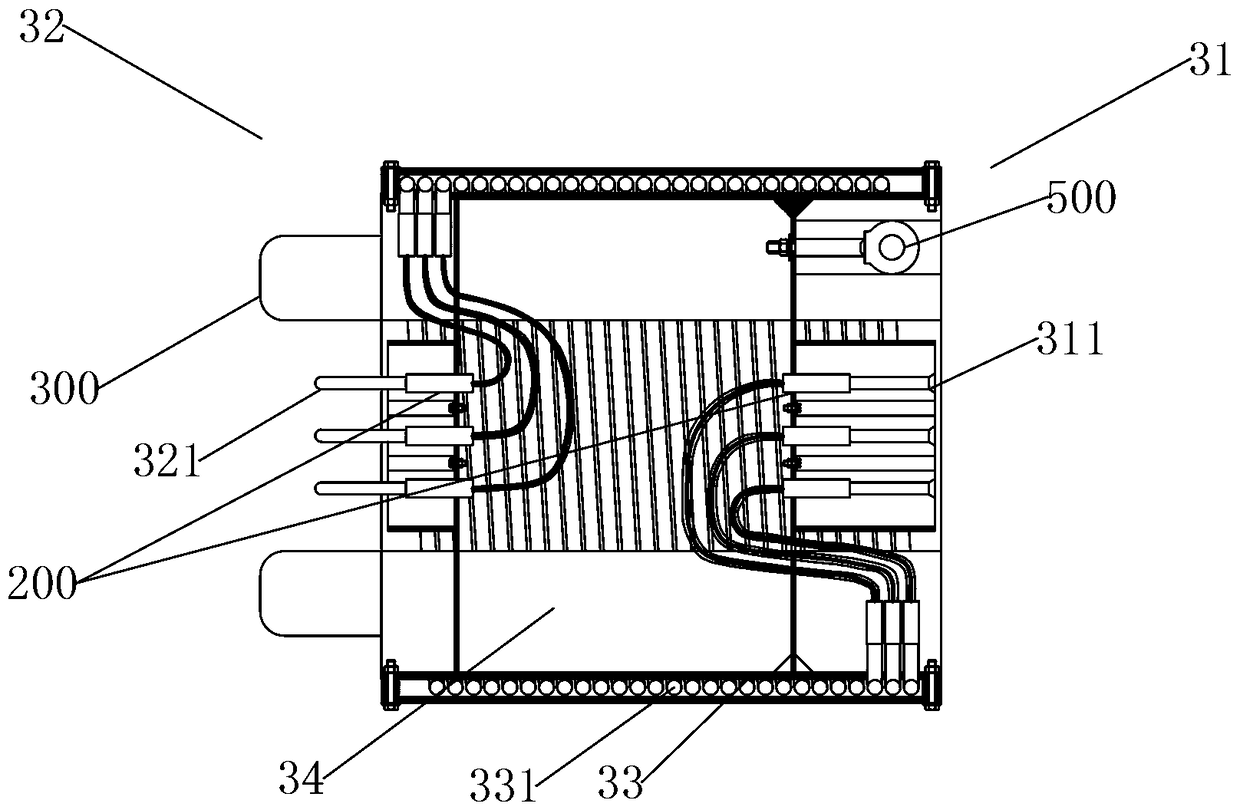

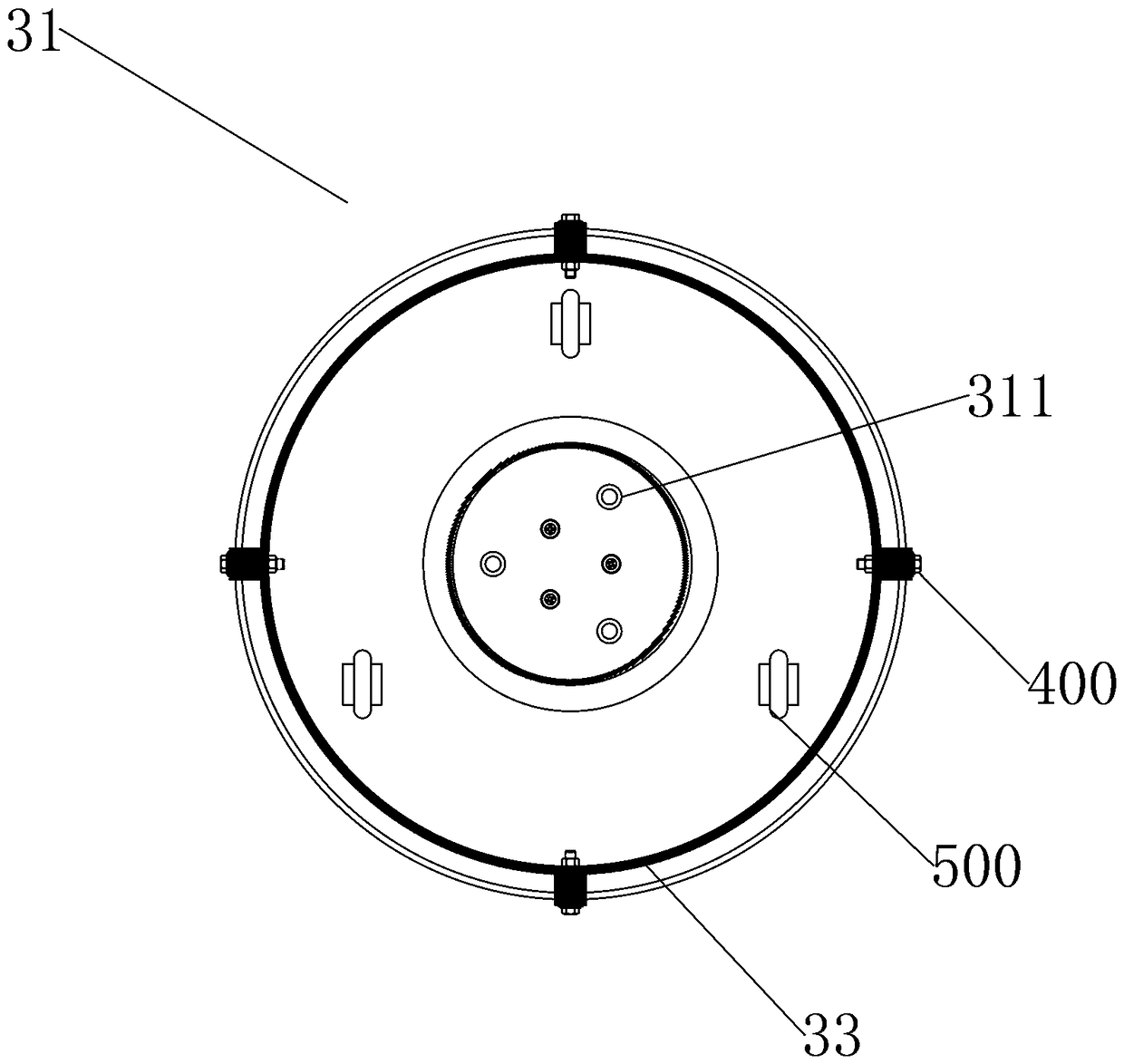

[0052] like Figure 1-Figure 12 As shown, a segmented plug-in heating rod includes a casing 1, a heating body installed in the inner cavity of the casing 1, a cover plate flange 5 that covers the heating body, and a heating element through the cover plate method. The junction box 6 connected to the blue sheet 5 and the heating body, the heating body includes: a split end post 2, a split heating post 3, a split cold end lead post 4, the split end post 2 and The split cold end lead posts 4 are connected by one or more split heating posts 3, wherein if the split heating posts 3 are greater than or equal to two, the adjacent two split heating posts 3 End-to-end connection, the segmented plug-in heating rod is connected by the split tail end column 2, the split heating column 3, and the split cold end lead post 4 of the multi-section device. Each device is an independent individual and can be connected according to The sequential assembly of the split tail end column 2, the split ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com