Sliding rail type parallel opening-closing electric claw

A slide rail and electric claw technology, applied in the field of robotics, can solve the problems of complex system control and uncontrollable opening and closing strokes of air claws, and achieve accurate control, simple structure, and satisfying clamping effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with specific embodiment and accompanying drawing, the present invention is further elaborated and illustrated:

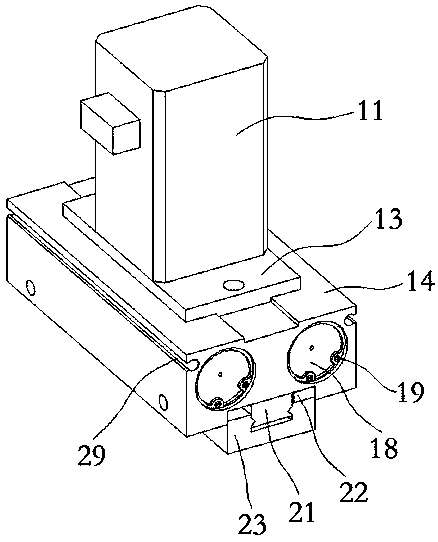

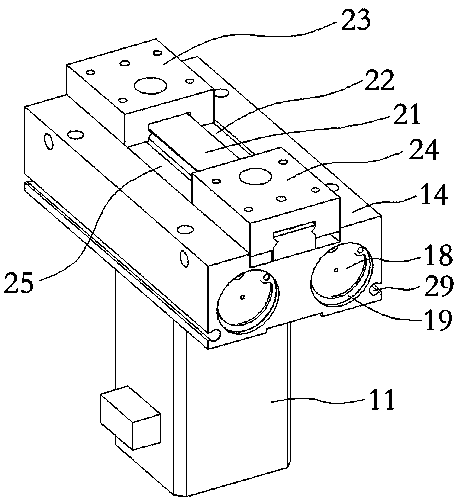

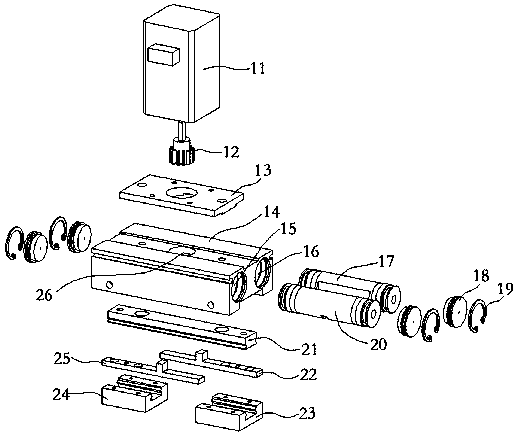

[0020] Please refer to figure 1 , figure 2 , image 3 and Figure 4 , a slide rail type parallel opening and closing electric gripper, including a cylinder 14, a motor 11, a left piston 20, a right piston 17, a left slider 24 and a right slider 23.

[0021] The side of the cylinder body 14 is provided with a left track through hole 15 and a right track through hole 16 parallel to the axis of the hole center, and the cylinder body 14 is vertically provided with a connecting through hole 26, and the connecting through hole 26 is located at the left track through hole 15 and the right track through hole 16. In the middle of the right track through hole 16, the connecting through hole 26 communicates with the left track through hole 15 and the right track through hole 16. The left piston 20 is located at the left track through hole 15 an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap