Reflective cone automatic retractable equipment

An automatic retractable, reflective cone technology, used in roads, buildings, road signs, etc., can solve the problems of workers' personal safety cannot be guaranteed, the reflective cone is labor-intensive, and the working environment is harsh, and achieves the liberation of manual labor and a high degree of mechanization. , The effect of efficient retraction and release operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with specific embodiments.

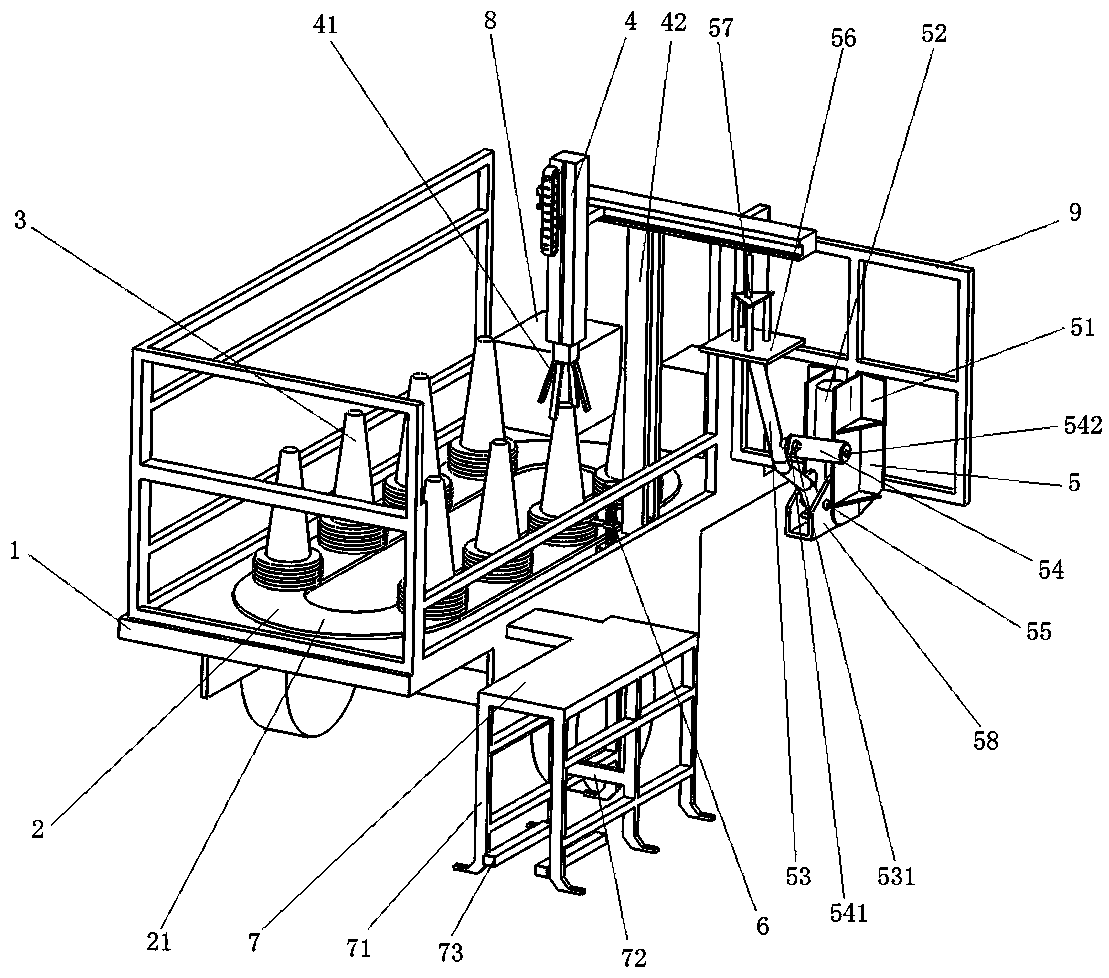

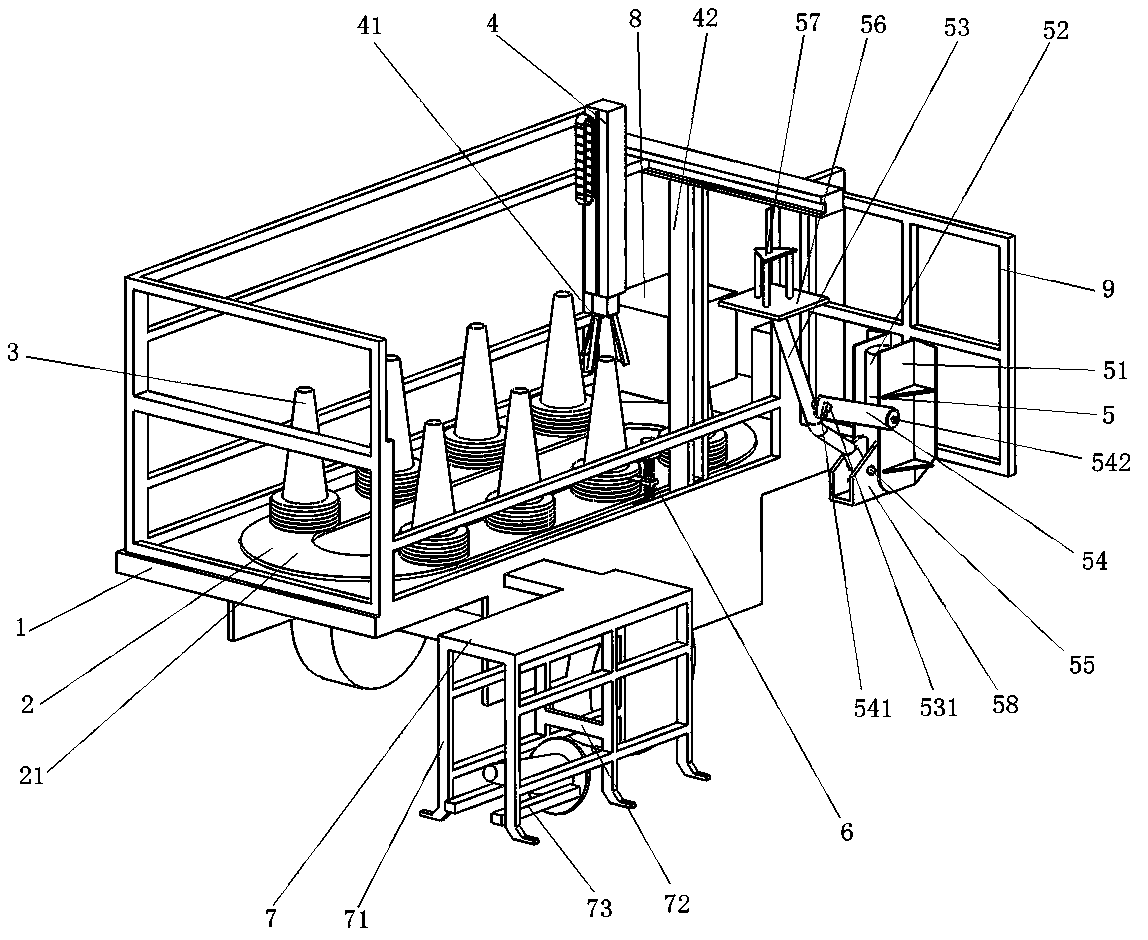

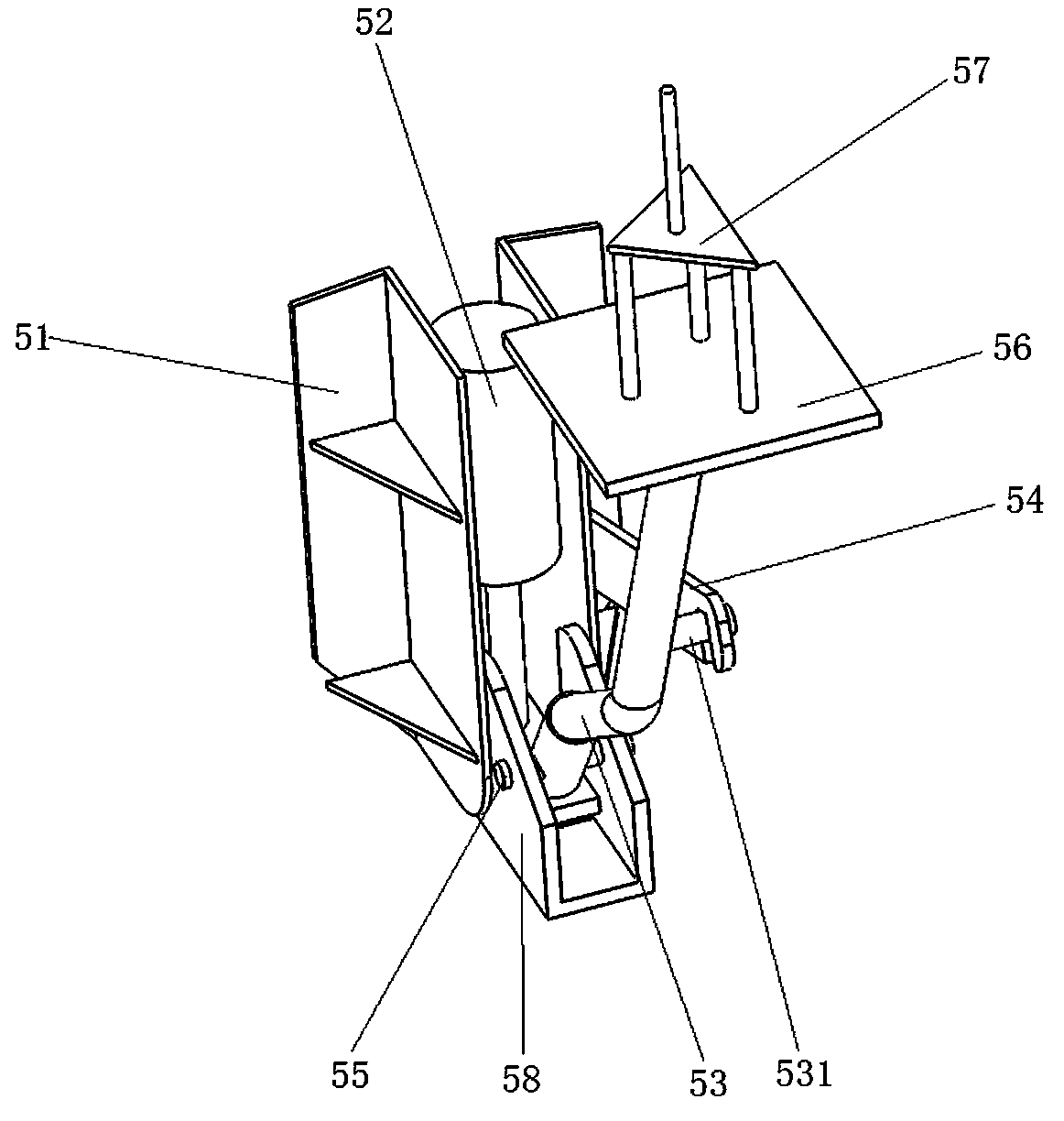

[0023] A reflective cone automatic retractable device, combined with Figure 1 to Figure 5 As shown, it includes a car body 1, a reflective cone feeding mechanism 2, a feeding and receiving mechanism 5, a pushing and swinging mechanism 7, a generator 8, a clamping mechanism 4, a bottom clamping mechanism 6 and a controller.

[0024] The car body 1 can drive the device to travel as a whole. The reflective cone feeding mechanism 2 is arranged on the vehicle body 1 and is used for intermittently feeding the reflective cone 3 . The feeding and receiving mechanism 5 is arranged on the outside of the car body 1, and is used for intermittently feeding and receiving the reflective cone. The pushing and swinging mechanism 7 is arranged on the outside of the car body 1, flush with the feeding and receiving mechanism 5, and is used for straightening and pushing down the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com