A safe and efficient manufacturing equipment for building ceramic plates

A technology for manufacturing equipment and ceramic plates, which is applied to the field of safe and efficient manufacturing equipment for building ceramic plates, can solve the problems of low work efficiency, time-consuming and laborious stirring and extrusion, and achieve the effects of improving work efficiency, stirring evenly, and facilitating work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

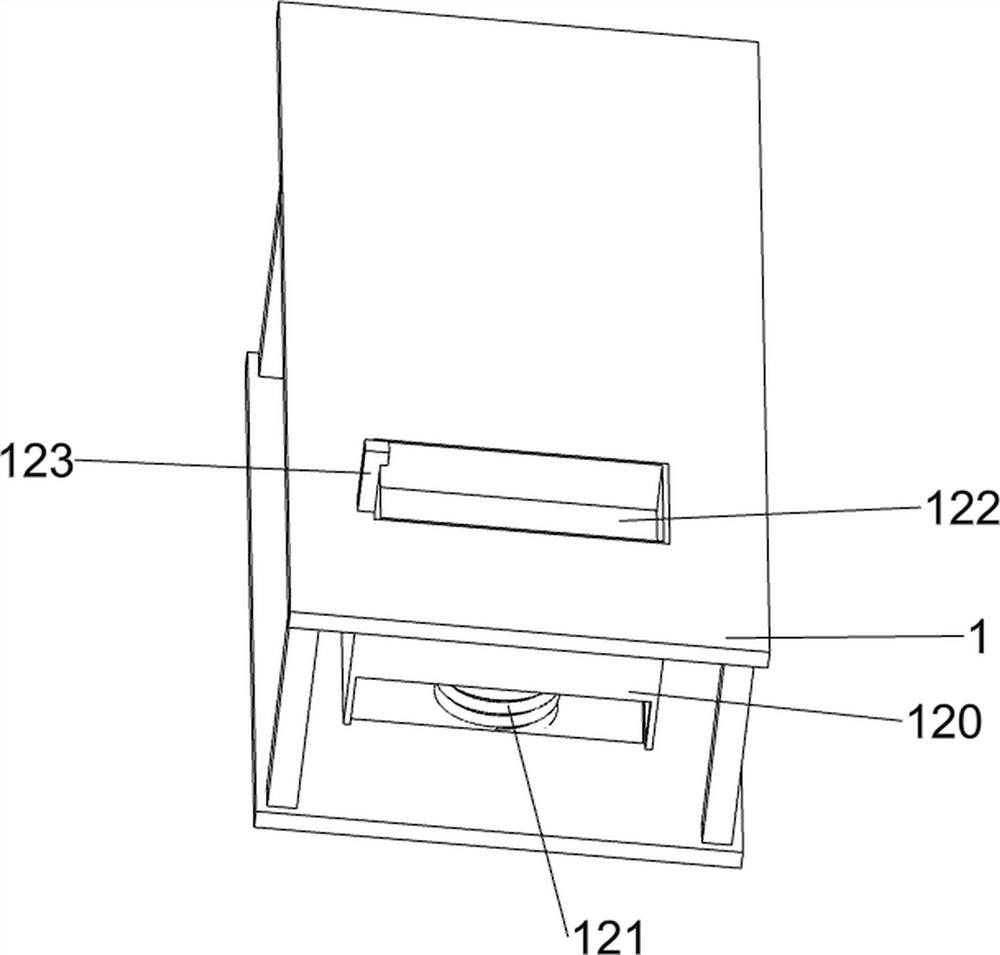

[0077] A safe and efficient manufacturing equipment for ceramic plates for construction, such as figure 1 As shown, it includes a first bracket 1, a second bracket 2, a servo motor 3, a motor support plate 4, a block assembly 5, a first bevel gear 6, a feeding mechanism 8, a stirring mechanism 9 and a pressing mechanism 10. A second bracket 2 is provided on the top of a bracket 1, and a chute 7 is provided on the right front side of the top of the second bracket 2, and a motor support plate 4 is slidably provided in the chute 7, and a servo motor 3 is provided on the top of the motor support plate 4, The left and right sides of the front right part of the top of the second support 2 are symmetrically provided with two block assemblies 5, the output shaft of the servo motor 3 is provided with a first bevel gear 6, and the left side of the top of the second support 2 is provided with a blanking mechanism 8 A stirring mechanism 9 is provided in the middle of the bottom of the sec...

Embodiment 2

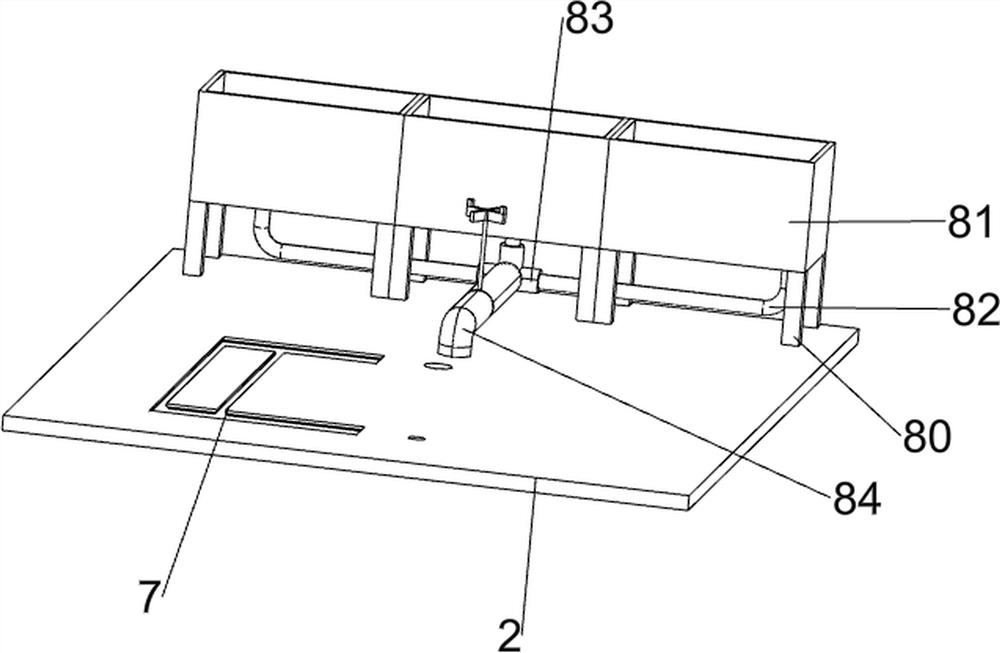

[0080] On the basis of Example 1, such as figure 2 , image 3 , Figure 4 and Figure 5 As shown, the blanking mechanism 8 includes a support rod 80, a raw material box 81, a first blanking tube 82, a square joint 83 and a second blanking tube 84, and the left and right sides of the left side of the top of the second bracket 2 are provided with six Three support bars 80, three raw material boxes 81 are arranged between the tops of the support bars 80, the bottom of the material box 81 is provided with a first feeding pipe 82, and a square joint 83 is arranged between the first feeding pipe 82 near one side, and the four corners The other end of the joint 83 is provided with a second feeding tube 84 , and the other end of the second feeding tube 84 passes through the middle part of the top of the second bracket 2 .

[0081] The raw materials for making the ceramic plates are put into different raw material boxes 81 respectively, the raw materials for making the ceramic plat...

Embodiment 3

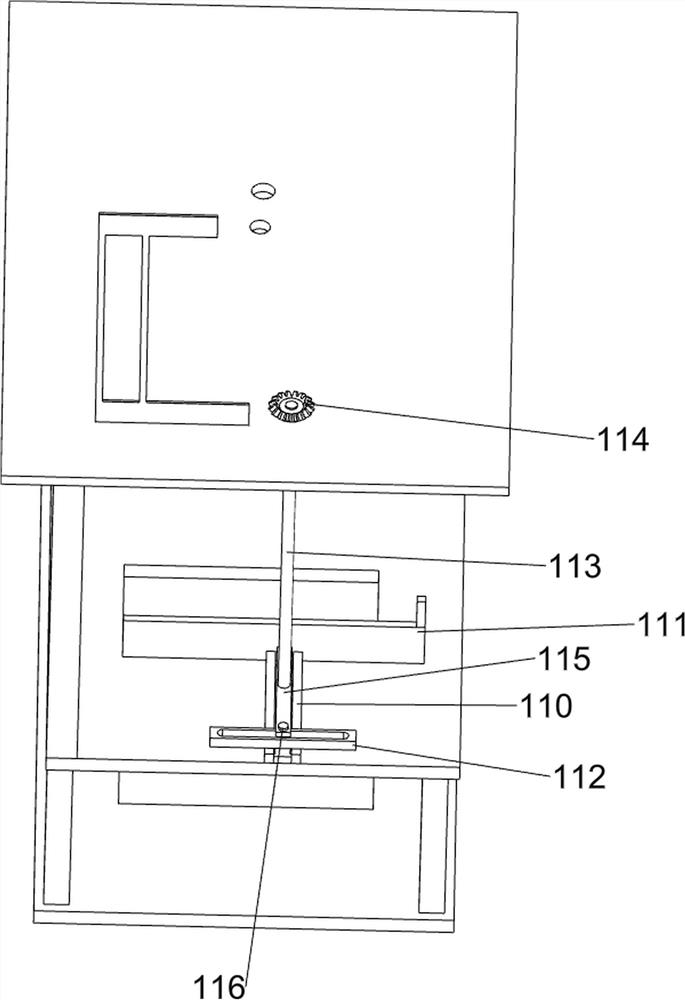

[0087] On the basis of Example 2, such as figure 1 , Figure 6 , Figure 7 and Figure 8 As shown, a propulsion mechanism 11 is also included, and the propulsion mechanism 11 includes a first slide rail 110, a first push plate 111, a push block 112, a second rotation rod 113, a third bevel gear 114, a first rotation block 115 and a push Rod 116, a first slide rail 110 is provided in the middle of the top right side of the first support 1, a first push plate 111 is slidably provided on the first slide rail 110, and a push block 112 is provided on the right side of the top of the first push plate 111. Two brackets 2 top right middle rotation type are provided with the second rotating rod 113, and the second rotating rod 113 tops are provided with the 3rd bevel gear 114, and the 3rd bevel gear 114 and the first bevel gear 6 are mutually meshed, and the second rotating rod 113 The bottom is provided with a first rotating block 115 , the other end of the first rotating block 115...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com