Half-elliptic distribution textured surface for radial sliding bearing

A semi-elliptical, radial sliding technology, used in sliding contact bearings, rotating bearings, bearings, etc., can solve problems such as no design scheme, and achieve reduced restriction, small friction coefficient, and high hydrodynamic pressure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

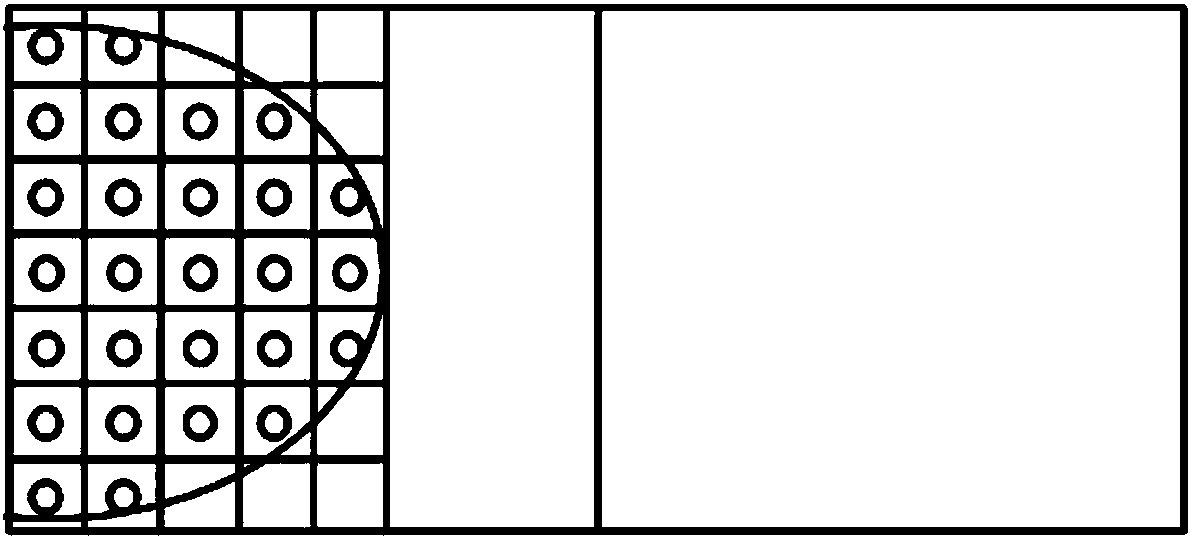

[0017] The invention optimizes the texture distribution on the surface of the bearing bush of the radial sliding bearing through a genetic algorithm to improve its tribological properties. Design drawing such as figure 1 shown. A semi-elliptical radial plain bearing texture arrangement at the entrance to the bearing deployment plane. Among them, the circular pit texture is based on the arrangement of a rectangular grid array, and the semi-ellipse with the minor semi-axis and major semi-axis lengths equal to 1 / 2 of the bearing width and 1 / 3 of the circumference is set as the textured surface range.

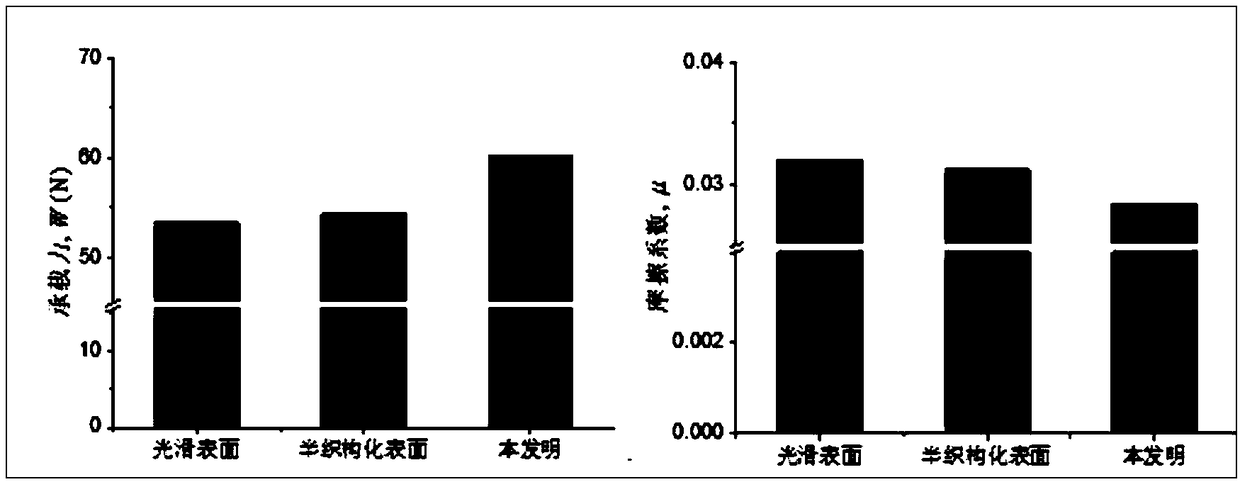

[0018] figure 2 is the histogram of the calculated tribological properties of bearings with semi-elliptical textured surface, semi-textured surface and smooth surface (B / L=0.47, ε=0.1). It can be seen that the semi-elliptical radial sliding be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com