Clamping-pushing two-stage linkage cherry-picking tool

A cherry and tool technology, applied in the field of two-level linkage cherry picking tools on the top of the clamp, can solve the problems of reducing labor intensity, drilling into the bushes, and working off the ground, so as to reduce labor intensity, ensure integrity, and avoid bending. waist effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

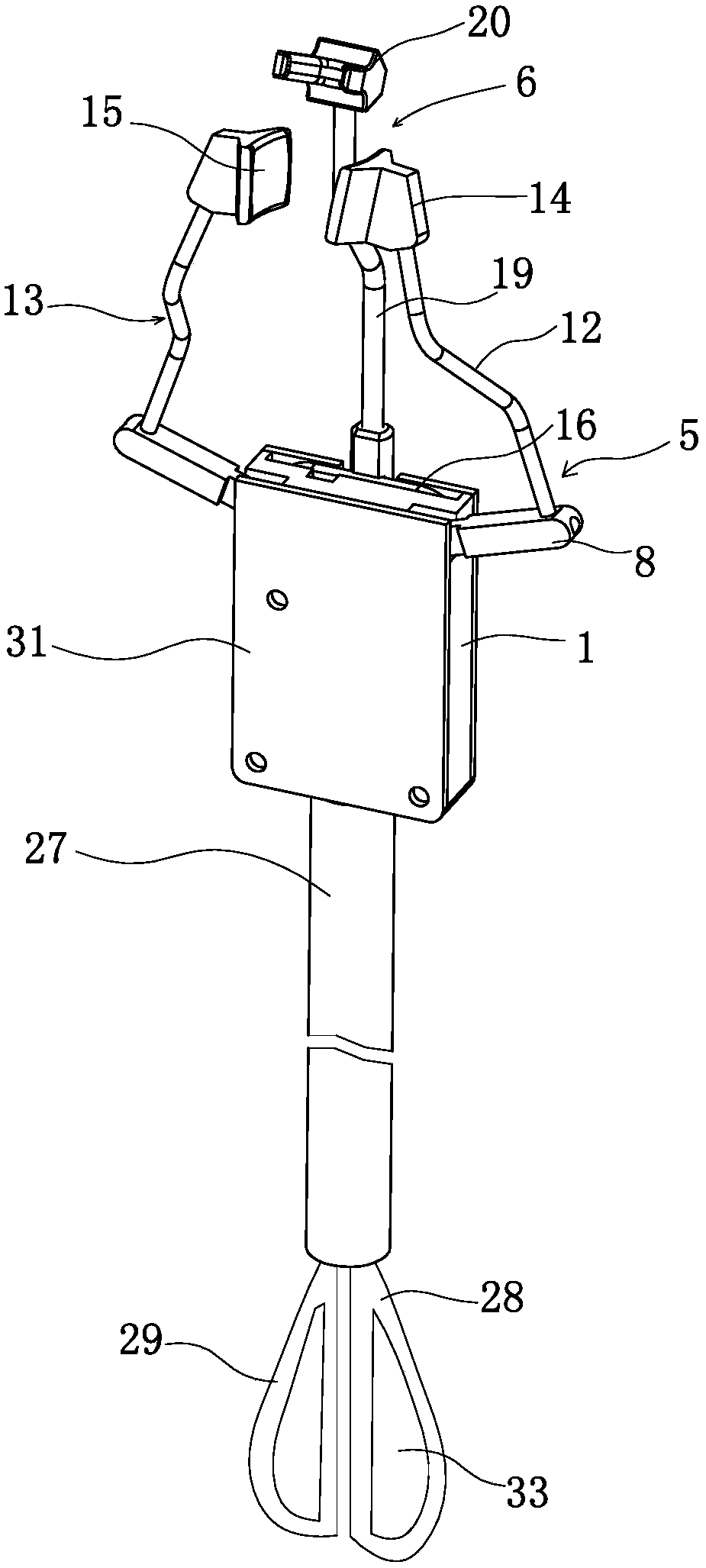

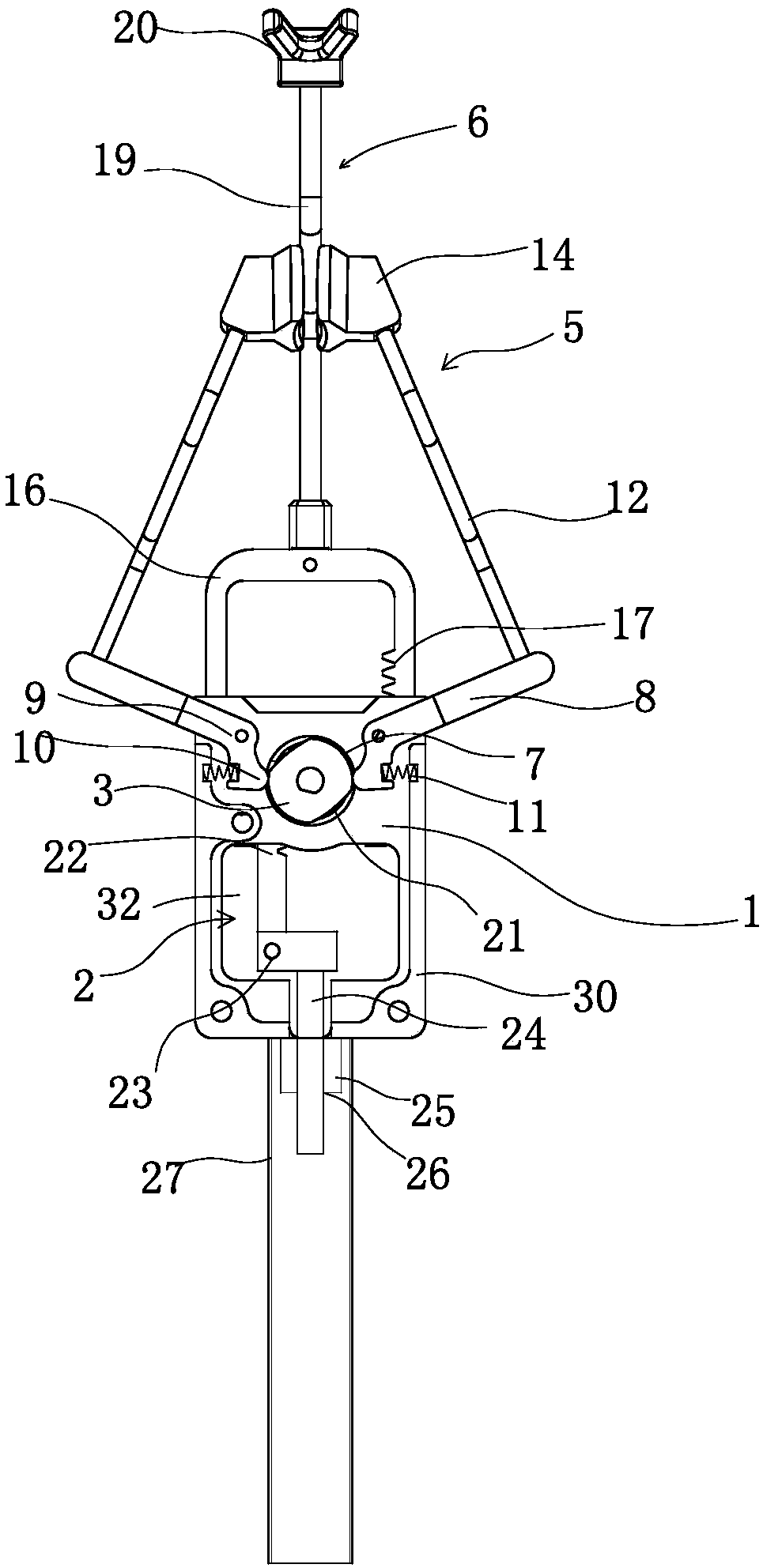

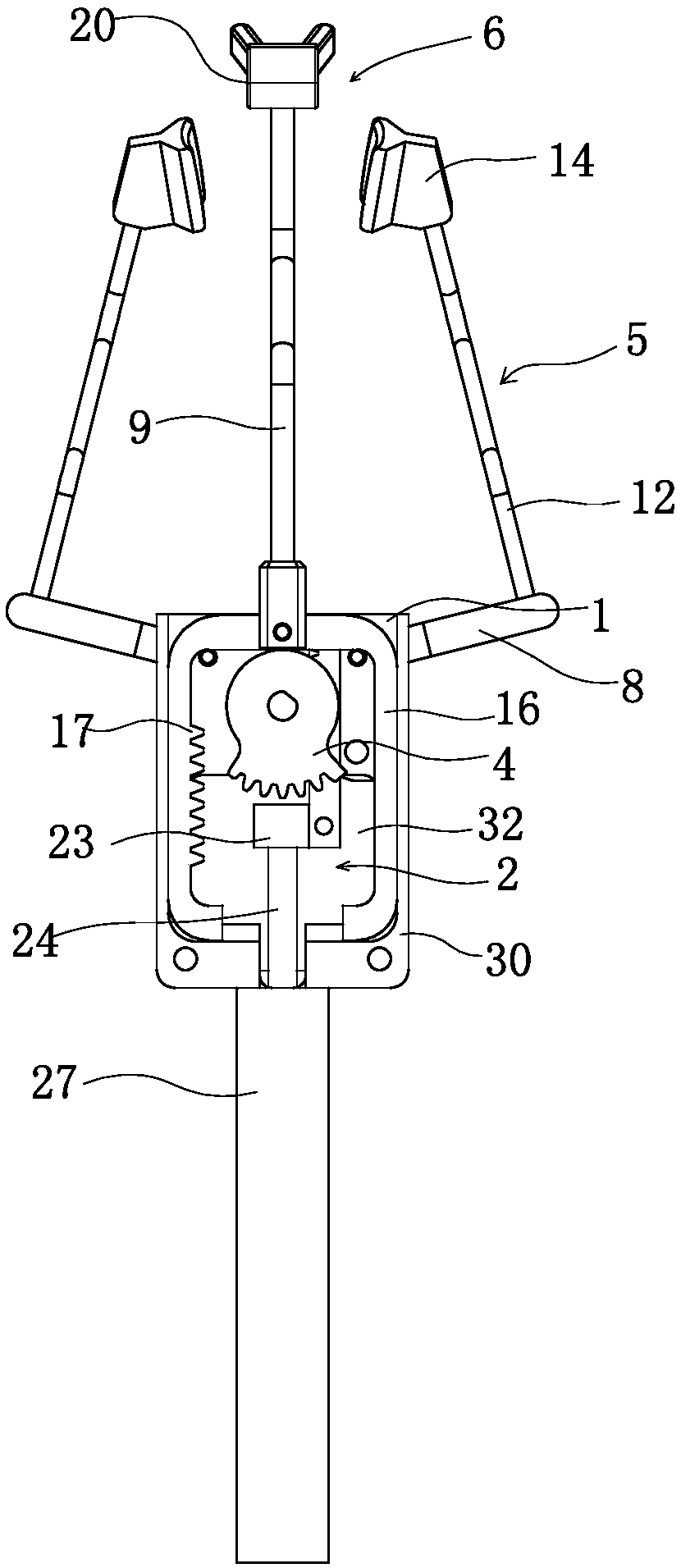

[0029] like Figure 1-2 As shown, the clamp top two-stage linkage cherry picking tool includes a bracket 1, and the bracket 1 is provided with a rotary drive device 2, and the rotary drive device 2 is fixedly connected with a cam 3 and an incomplete gear 4. The cam 3 is connected with the clamping assembly 5 through the cam curved surface, the incomplete gear 4 is meshed with the ejector assembly 6, and the cam 3 is symmetrically provided with two far rest curved surfaces 7 .

[0030] In the process of picking cherries, the rotary drive mechanism 2 drives the cam 3 and the incomplete gear 4 at the same time, and the cam 3 rotates and drives the clamping assembly 5 to shrink and clamp the branches inwardly. Rotate to the position engaged with the ejector assembly 6, and the ejector assembly 6 stops and does not move. The driven part 10 moves to the far rest curved surface 7 on the cam 3, and the points on the far rest curved surface 7 are equal to the center of the cam 3, and ...

Embodiment 2

[0043] The basic principle of the second embodiment is the same as that of the first embodiment, except that the rotary drive device 2 is different. In the second embodiment, the rotary drive device 2 includes a miniature disc motor, and the miniature disc motor is provided with two output ends, the output The ends are fixedly connected with the cam 3 and the incomplete gear 4 respectively. The miniature disc motor is electrically connected to the control switch at the hand-held part at the end of the hand lever. The advantage of the second embodiment is that the driving power is provided by the miniature disc motor, which further reduces labor intensity.

Embodiment 3

[0045] The basic principle of embodiment three is the same as that of embodiment one, the difference is that the hand lever 27 is telescopic, and the end of the hand lever 27 away from the support 1 is provided with a reel, the reel is connected with the guide rod 24 by a steel cable, and the reel A rotating motor is arranged on the top, and the rotating motor is connected with a control switch arranged on the handle bar 27 . The advantage of the third embodiment is that the user can adjust the length of the hand lever 27 according to the height of the tree. At the same time, the actual length of the steel cable can be adjusted through the winding wheel, and the power is provided by a rotating motor to further reduce the labor intensity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com