Full automatic special-shaped three-dimensional mask production machine

A fully automatic, production machine technology, applied in the direction of protective clothing, clothing, applications, etc., can solve the problems of low production efficiency, high labor cost, missing welding, etc., achieve the effect of reducing labor cost and labor intensity, and improving the productivity level of masks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

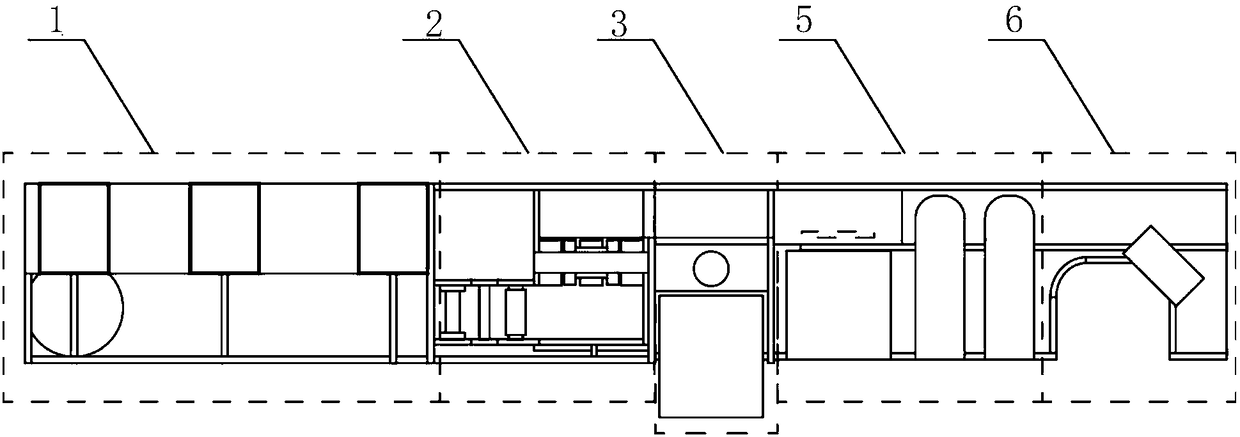

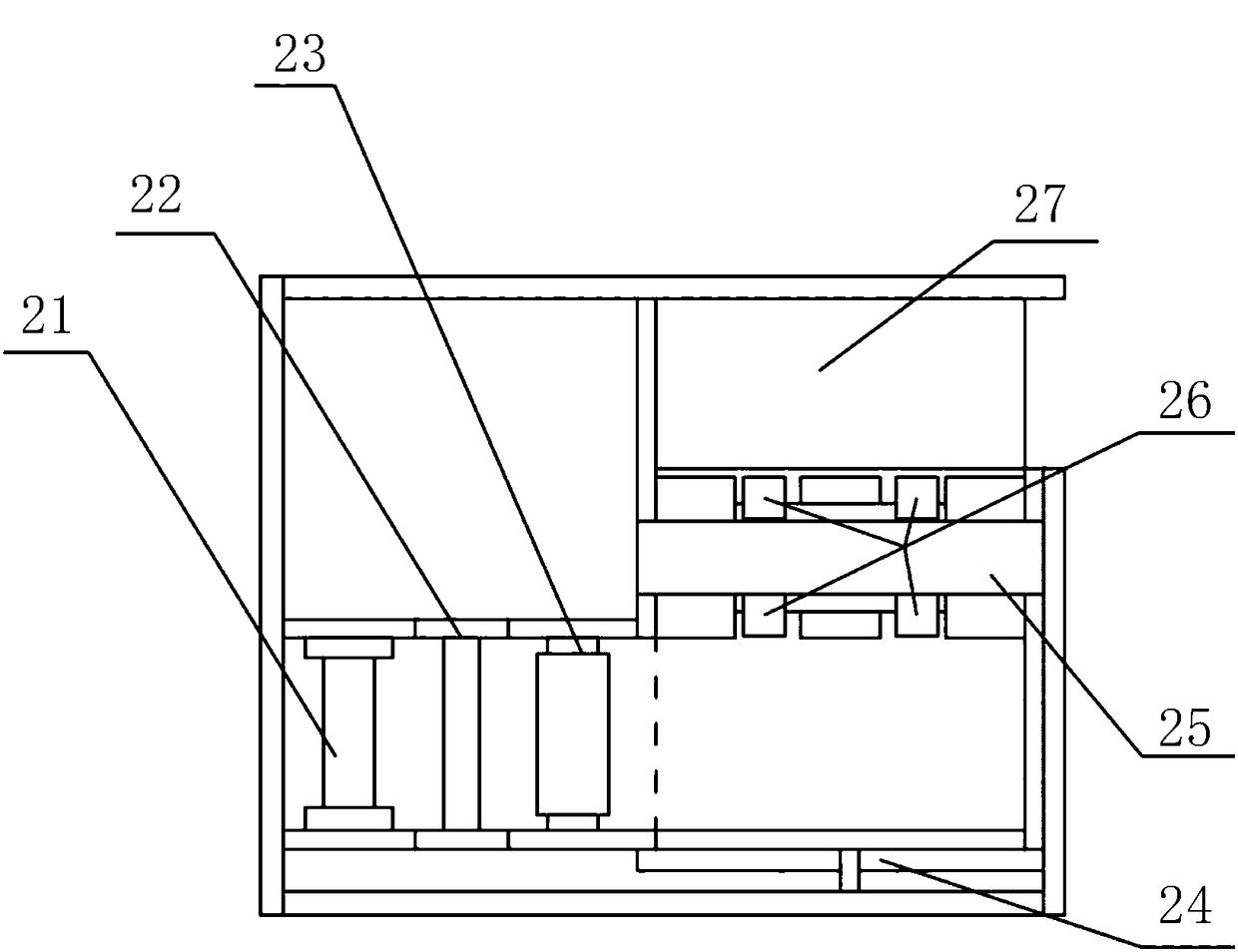

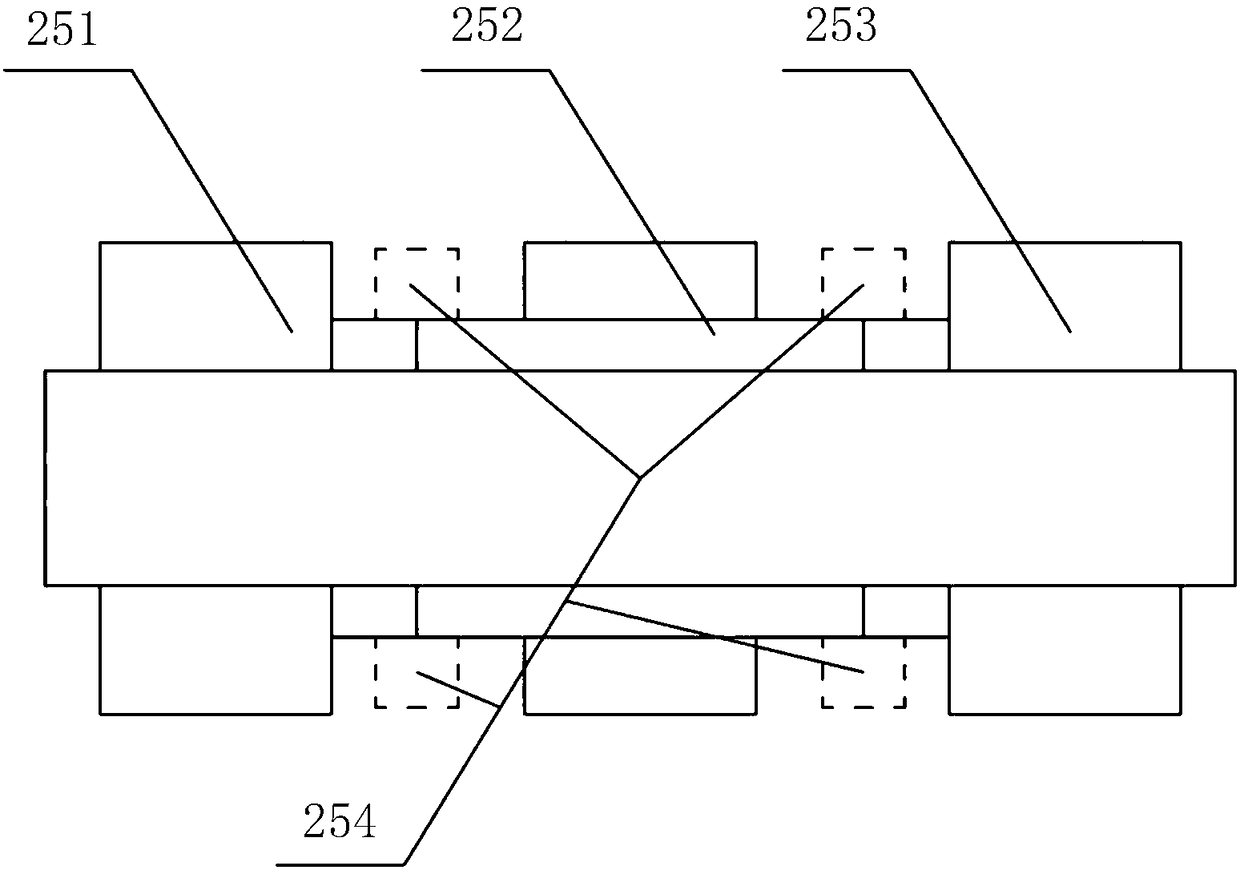

[0028] figure 1 It is a schematic diagram of embodiment one of the automatic special-shaped three-dimensional mask production machine of the present invention, figure 2 It is a schematic diagram of an embodiment of the forming device in the automatic special-shaped three-dimensional mask production machine of the present invention, image 3 It is a schematic diagram of an embodiment of the folding group in the automatic special-shaped three-dimensional mask production machine of the present invention, Figure 4 It is a schematic diagram of an embodiment of a bottom cloth welding device in a fully automatic special-shaped three-dimensional mask production machine of the present invention. As shown in the figure, as Embodiment 1 of the present invention, a fully automatic special-shaped three-dimensional mask production machine includes sequentially arranged chipping devices 1. Forming device 2, base fabric welding device 3, ear strap sponge strip welding device 5, and detecti...

Embodiment 2

[0035] Figure 5 It is a schematic diagram of the second embodiment of the automatic special-shaped three-dimensional mask production machine of the present invention, Image 6 It is a schematic diagram of an embodiment of an integrated device for sheeting and forming a base cloth fusion and welding in a fully automatic special-shaped three-dimensional mask production machine of the present invention. The welding device 3 is an integrally formed piece-forming bottom fabric welding mechanism 4. The forming device 2 includes a pressure-feeding group 27, an edge-melting group 21, a half-folding group 25, a spot-melting group 26, a cutter group 22, and a horizontal melting group 23. The bottom welding device 3 includes a base cloth roll group 31 and a cloth punching group 32 . The pressure-feeding group 27 is located between the chipping device 1 and the edge melting group 21 , and the material passing through the chipping device 1 is transported to the side-melting group 21 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com