Method for producing anti-stress growth promoting fodder additive

A feed additive and production method technology, applied in animal feed, animal feed, application, etc., can solve problems that have not been reported, and achieve the effects of inhibiting the occurrence of hazards, low production costs, and promoting growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

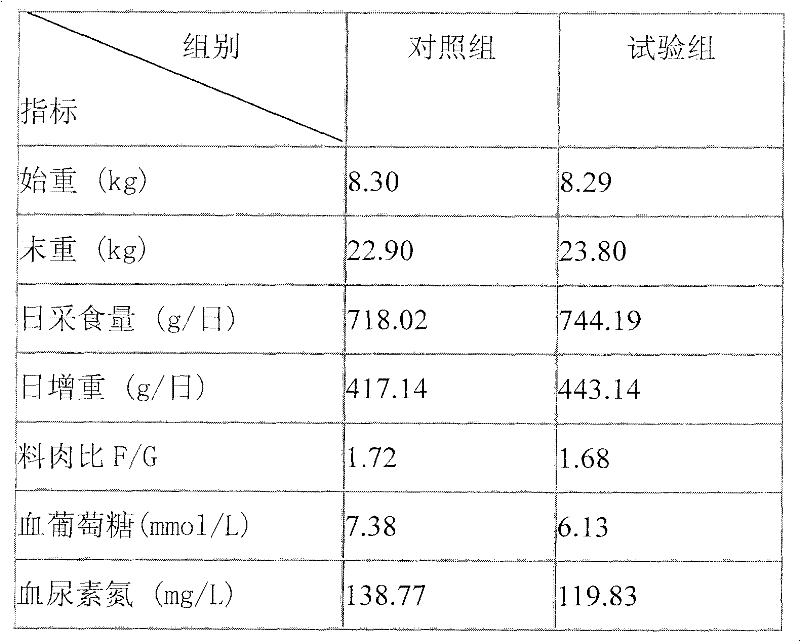

Examples

Embodiment 1

[0019] Embodiment 1: (a kind of production method 1 of anti-stress growth-promoting feed additive)

[0020] Follow these steps:

[0021] (1) Seed liquid culture of Saccharomyces cercvisiae strain 2.1952: insert the original slant strain of Saccharomyces cerevisiae into the test tube seed medium, and cultivate it statically at 26-28°C for 30 hours to become test tube seeds; Put the seeds in the test tube into the seed medium of the Erlenmeyer flask, and after static cultivation at 26-28°C for 24 hours, they will become seeds of the flask; Static culture for 20h to become Saccharomyces cerevisiae fermented seed liquid, for subsequent use; the seed culture medium of above-mentioned test tube, Erlenmeyer flask and Karl Fischer tank all adopts 10 ° of Bx saccharified wort culture medium;

[0022] The preparation method of the 10°Bx saccharification wort culture medium: take a certain amount of barley malt, crush it, add 60°C water 4 times the weight of the malt, keep saccharificat...

Embodiment 2

[0026] Embodiment 2. (a kind of production method 2 of anti-stress growth-promoting feed additive)

[0027] In this example, the seed liquid culture of step (1) Saccharomyces cerevisiae: After the inoculated test tube seed medium was cultured statically at 26-28°C for 27 hours; After static culture at 28°C for 22 hours; insert 10% of the inoculum into the seed culture medium of the Karl Fischer jar, and cultivate Saccharomyces cerevisiae fermented seed liquid through static culture at 26~28°C for 18 hours; step (2) seed liquid cultivation of Armillaria armillaria: After the inoculated Erlenmeyer flask culture medium was cultured on a shaker at 26-28°C and 180-200rpm for 6.5 days; it was inserted into the medium of the first-level seed tank according to the inoculum amount of 8%, and was ventilated at 26-28°C and 180-200rpm. The amount is 1:0.5 after culturing for 60 hours; access the culture medium of the secondary seed tank according to 10% inoculum amount, and cultivate it f...

Embodiment 3

[0028] Embodiment 3. (a kind of production method 3 of anti-stress growth-promoting feed additive)

[0029] In this example, step (1) Saccharomyces cerevisiae seed liquid culture: After the inoculated test tube seed medium was cultured statically at 26-28°C for 24 hours; After static culture for 20 hours; insert 10% inoculum into the seed culture medium of the Karst jar, and statically cultivate at 26-28°C for 16 hours to form a fermented seed liquid of Saccharomyces cerevisiae; After the culture medium is cultured on a shaker at 26-28°C and 180-200rpm for 6.0 days; the inoculation amount is 5% into the medium of the first-level seed tank, and the culture medium is 26-28°C, 180-200rpm, and the ventilation rate is 1:0.6 After culturing for 48 hours under the same conditions; 5% inoculation amount was inserted into the medium of the secondary seed tank, and cultivated under the same conditions for 72 hours to form Armillaria fermented seed liquid; the composition of the medium w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com