An assembly device for thermal insulation pipes

A technology for thermal insulation pipes and assembling devices, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of high defective rate of thermal insulation pipes, low assembly efficiency, large labor costs, etc., to liberate labor costs and improve quality. , the effect of reducing the defective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

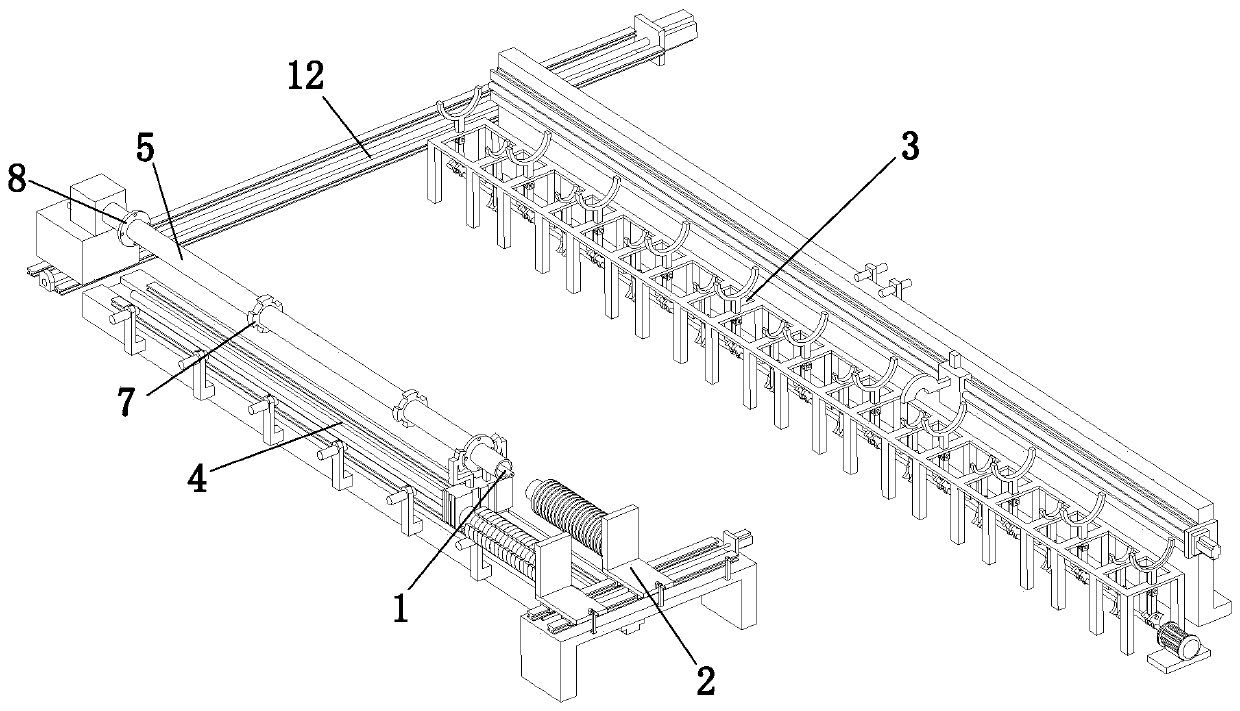

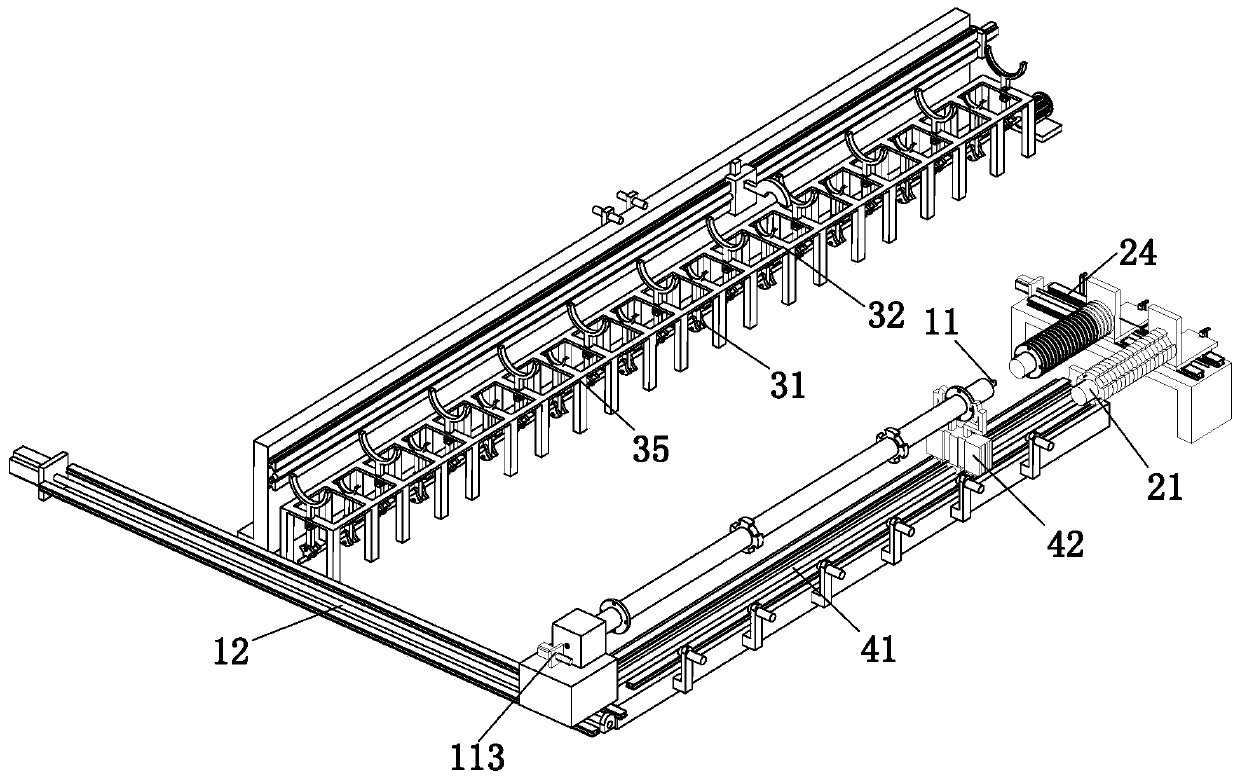

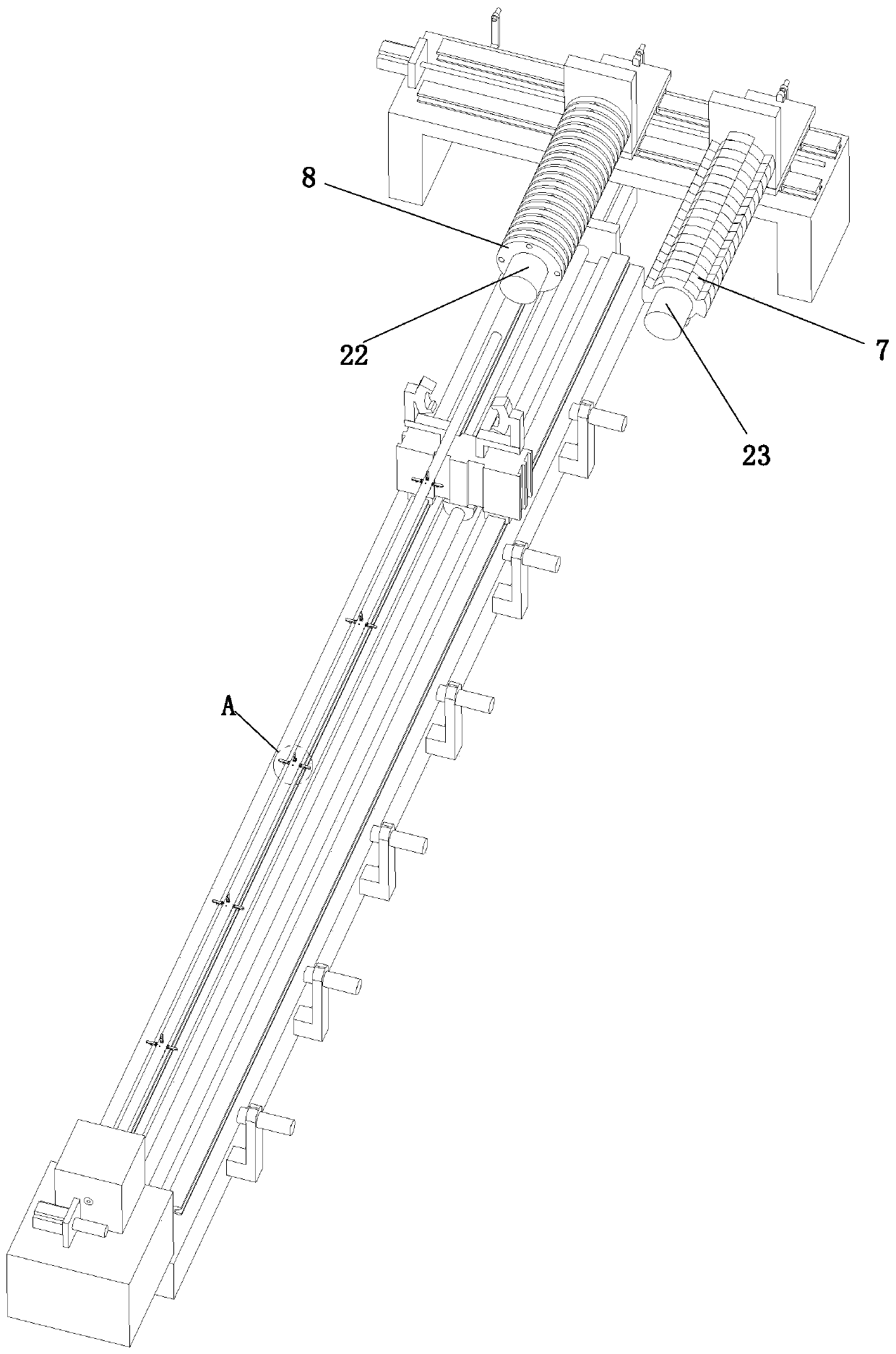

[0023] refer to Figure 1 to Figure 7 The shown assembly device for thermal insulation pipelines includes a supporting device 1 for carrying thermal insulation pipelines, a first feeding material for fitting snap rings 7 and plugs 8 on inner pipelines 5 The device 2 and the second feeding device 3 for transporting the inner pipe 5 and the outer pipe 6 to the supporting device 1, the supporting device 1 includes a supporting assembly 11 for supporting the heat-insulating pipe and for driving The supporting assembly 11 is a first driving assembly that travels back and forth between the first feeding device 2 and the second feeding device 3, and the first feeding device 2 includes a loading assembly for carrying the snap ring 7 and the plug 8 21 and a second drive assembly for driving the loading assembly 21 to move, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com