Wall surface polishing equipment for decoration

A technology of equipment and grinding heads, which is used in grinding/polishing equipment, metal processing equipment, machine tools suitable for grinding workpiece planes, etc. problems, to achieve the effect of reducing labor intensity, simple structure, and improving flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

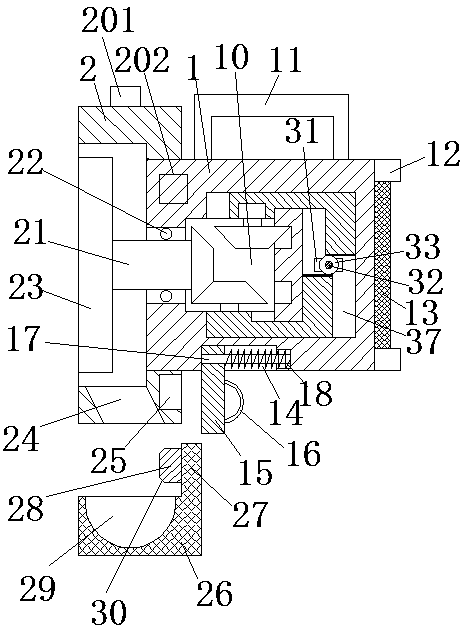

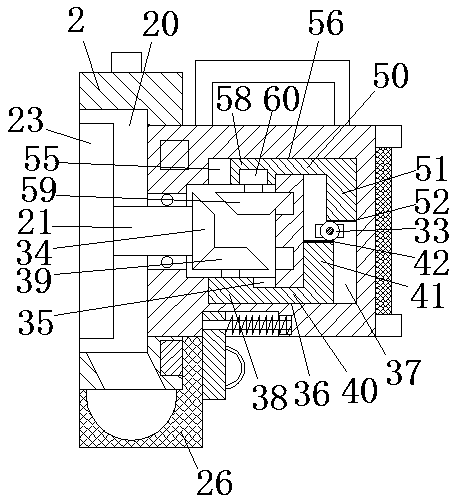

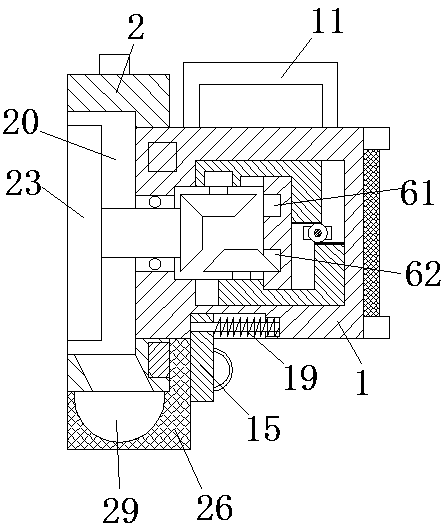

[0019] like Figure 1-Figure 4 As shown, a wall grinding device for decoration of the present invention includes a main body 1 and a housing 2 fixedly arranged at the left end of the main body 1. The housing 2 is provided with a slot 20 with an opening facing left. The main body 1 A grip handle 11 is fixedly arranged on the top end surface, and feet 12 are symmetrically arranged up and down on the right end surface of the main body 1, and a push pad 13 fixedly connected to the right end surface of the main body 1 is arranged between the two feet 12, The bottom of the housing 2 is detachably provided with a dust collecting device, the bottom of the right end surface of the housing 2 is provided with a hanging groove 25, and the bottom end surface of the main body 1 is provided with a pressing assembly for pressing the dust collecting device. A grinding head 23 is arranged in the groove 20, an inclined groove 24 is arranged in the bottom end wall of the slot 20, a driving device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com