Log shredding device for papermaking

A shredding device and log technology, applied in the direction of manufacturing tools, wood processing appliances, etc., can solve the problems of time-consuming, labor-intensive, slow shredding, uneven shredding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

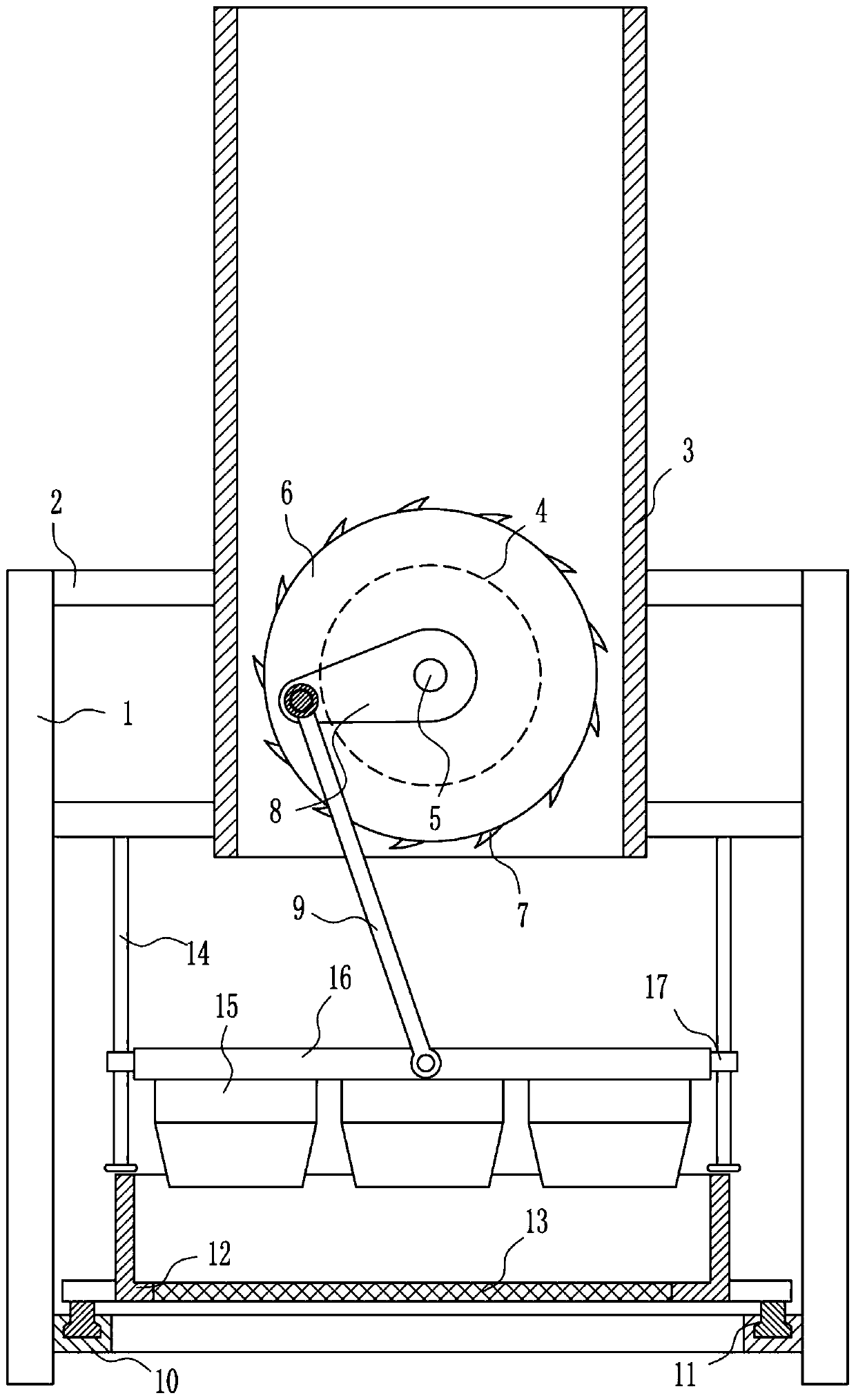

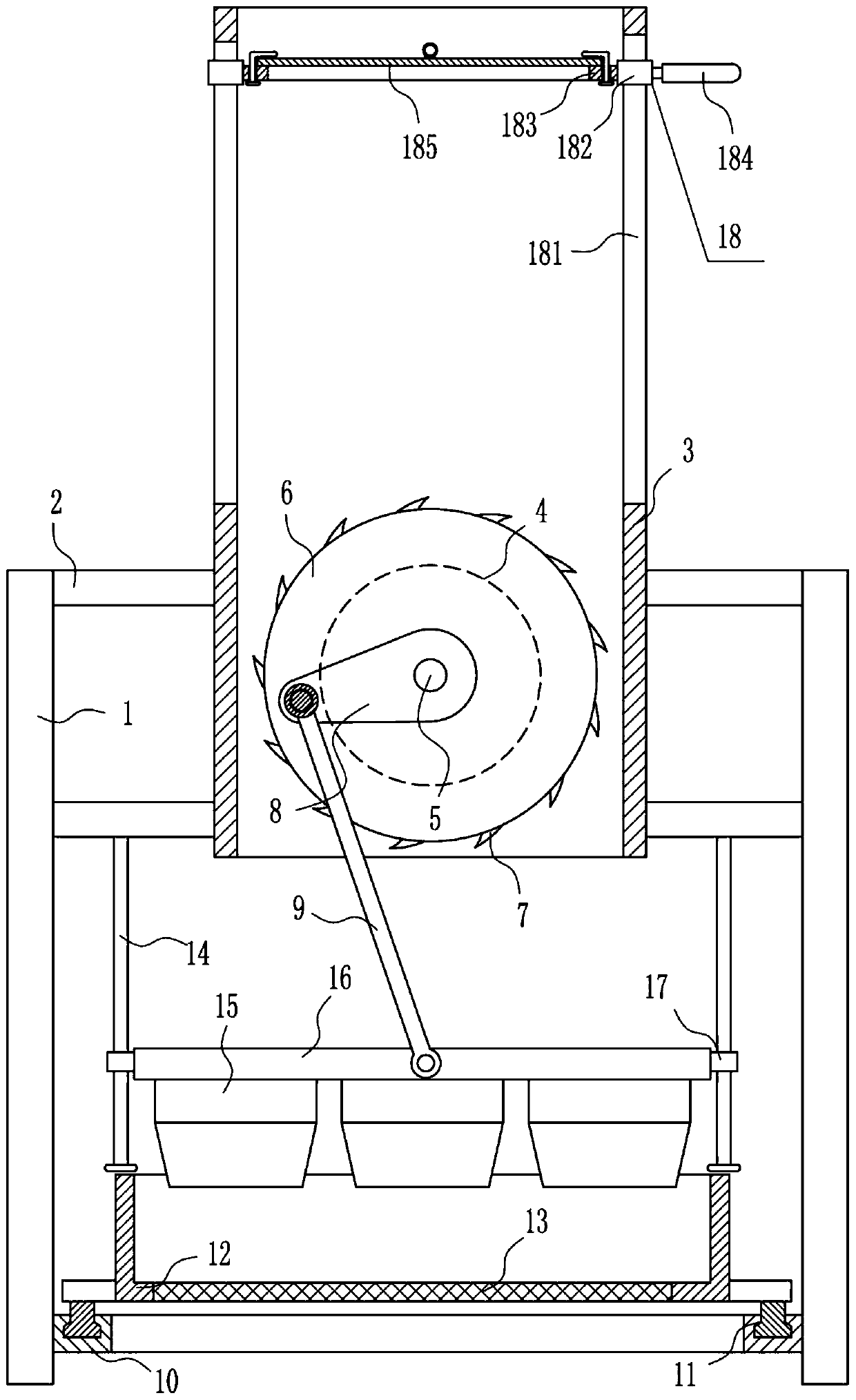

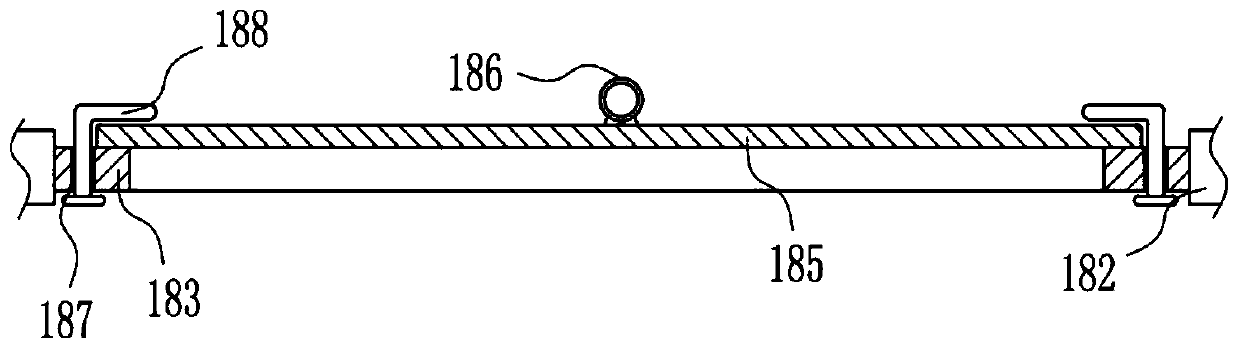

Embodiment 1

[0025] A log shredding device for papermaking, such as Figure 1-6 As shown, it includes a leg 1, a cross bar 2, a cylinder 3, a first motor 4, a rotating shaft 5, a drum 6, a planer 7, a movable block 8, a connecting rod 9, an annular slide rail 10, an annular slider 11, Frame body 12, screen plate 13, guide rod 14, cutter 15, horizontal plate 16 and guide sleeve 17, horizontal rods 2 are symmetrically installed on the inner sides of the left and right sides of the legs 1, and the inner ends of the four horizontal rods 2 A cylinder 3 is installed between them, and a rotating shaft 5 is installed between the lower part of the inner rear side of the cylinder 3 and the lower part of the front side in a rotating manner. The drum 6 is installed on the rotating shaft 5, and the planer 7 is installed on the outer surface of the drum 6 at even intervals. A movable block 8 is installed on the front end of the rotating shaft 5, and the movable block 8 is located on the outside of the c...

Embodiment 2

[0027] A log shredding device for papermaking, such as Figure 1-6 As shown, it includes a leg 1, a cross bar 2, a cylinder 3, a first motor 4, a rotating shaft 5, a drum 6, a planer 7, a movable block 8, a connecting rod 9, an annular slide rail 10, an annular slider 11, Frame body 12, screen plate 13, guide rod 14, cutter 15, horizontal plate 16 and guide sleeve 17, horizontal rods 2 are symmetrically installed on the inner sides of the left and right sides of the legs 1, and the inner ends of the four horizontal rods 2 A cylinder 3 is installed between them, and a rotating shaft 5 is installed between the lower part of the inner rear side of the cylinder 3 and the lower part of the front side in a rotating manner. The drum 6 is installed on the rotating shaft 5, and the planer 7 is installed on the outer surface of the drum 6 at even intervals. A movable block 8 is installed on the front end of the rotating shaft 5, and the movable block 8 is located on the outside of the c...

Embodiment 3

[0030] A log shredding device for papermaking, such as Figure 1-6 As shown, it includes a leg 1, a cross bar 2, a cylinder 3, a first motor 4, a rotating shaft 5, a drum 6, a planer 7, a movable block 8, a connecting rod 9, an annular slide rail 10, an annular slider 11, Frame body 12, screen plate 13, guide rod 14, cutter 15, horizontal plate 16 and guide sleeve 17, horizontal rods 2 are symmetrically installed on the inner sides of the left and right sides of the legs 1, and the inner ends of the four horizontal rods 2 A cylinder 3 is installed between them, and a rotating shaft 5 is installed between the lower part of the inner rear side of the cylinder 3 and the lower part of the front side in a rotating manner. The drum 6 is installed on the rotating shaft 5, and the planer 7 is installed on the outer surface of the drum 6 at even intervals. A movable block 8 is installed on the front end of the rotating shaft 5, and the movable block 8 is located on the outside of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com