Mirror surface glue film laminating equipment for processing automobile rearview mirror heating sheet

A technology of automobile rearview mirror and heating sheet, applied in the field of lamination, can solve the problems of poor uniformity of heating sheet, achieve ideal working effect, affect the flatness of pressing roller, etc., to ensure smooth fit, improve work stability and Work effect, high degree of automation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

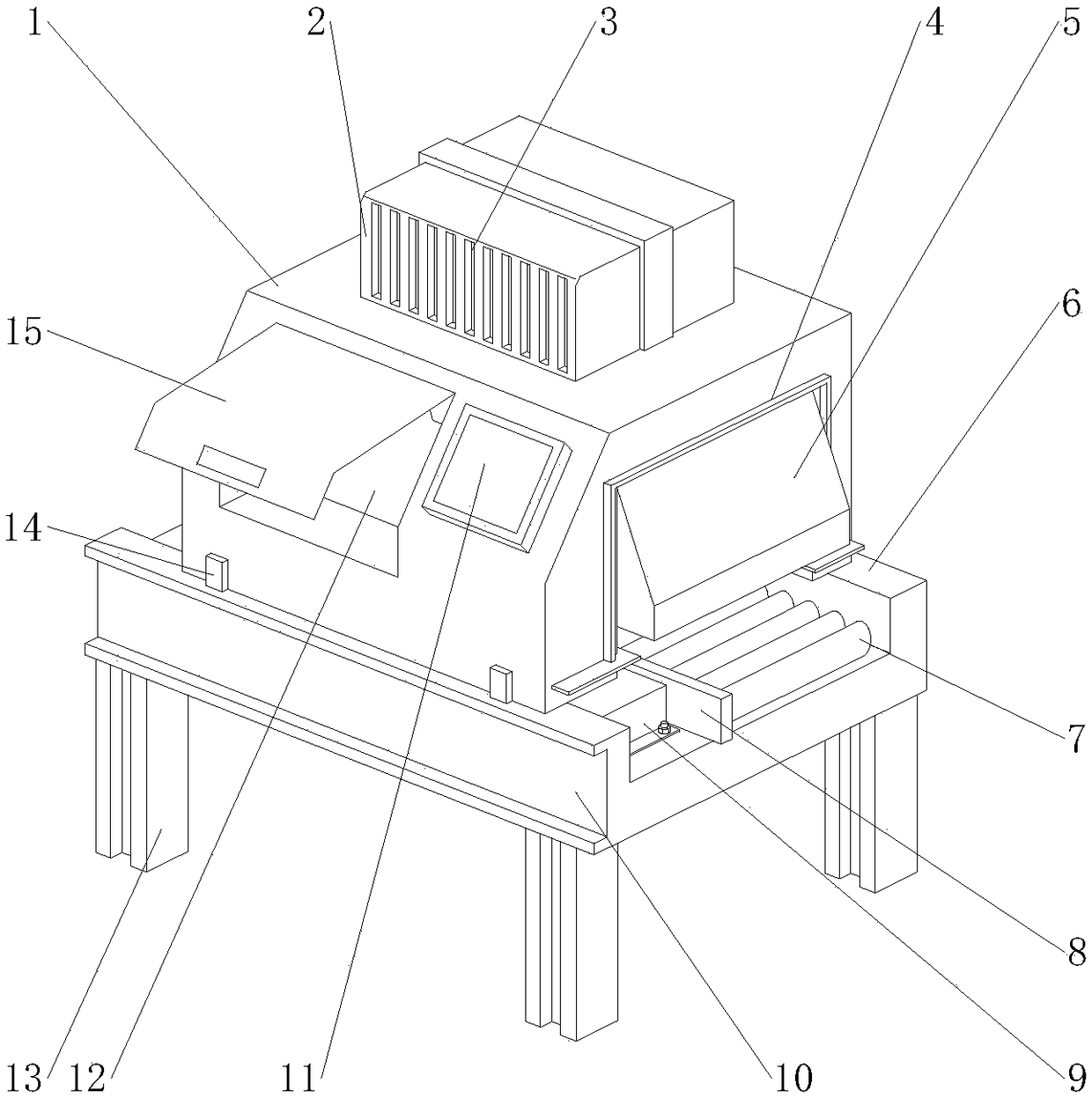

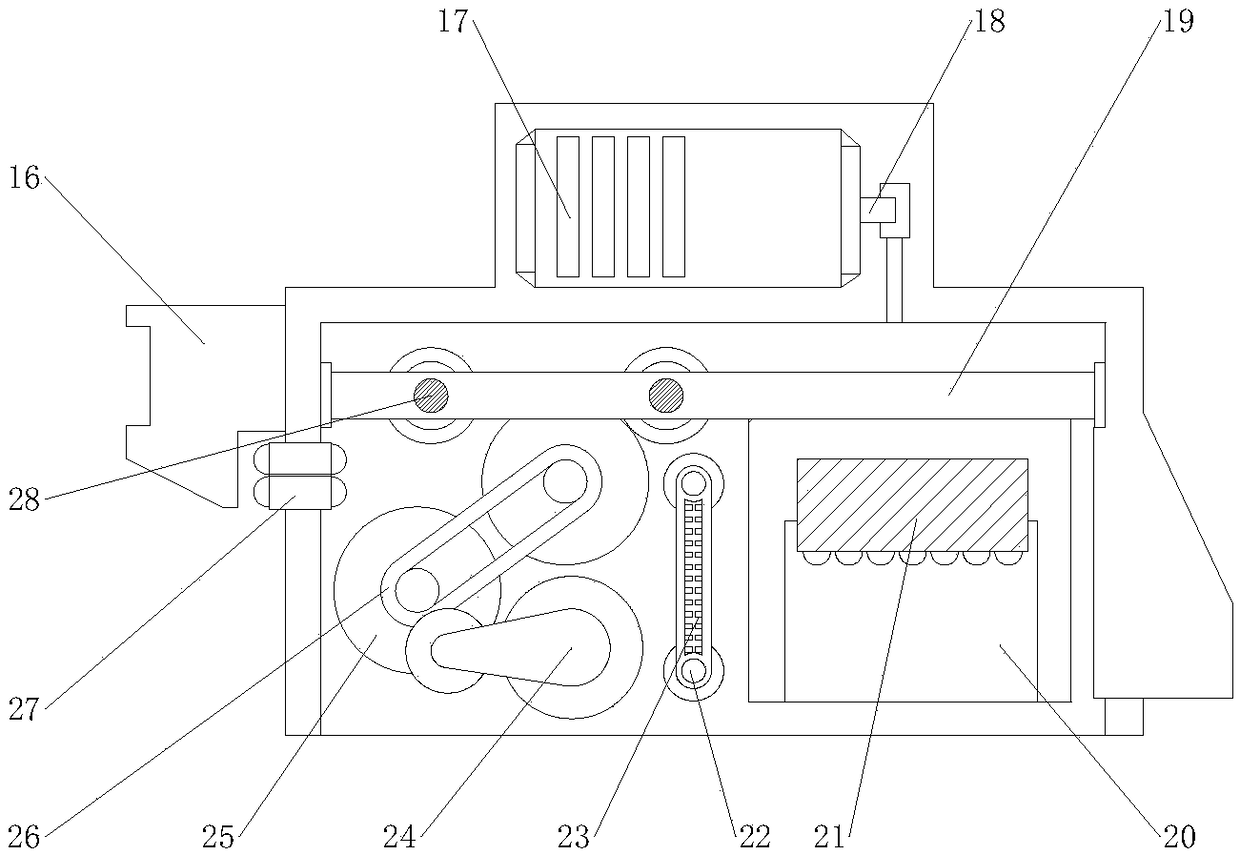

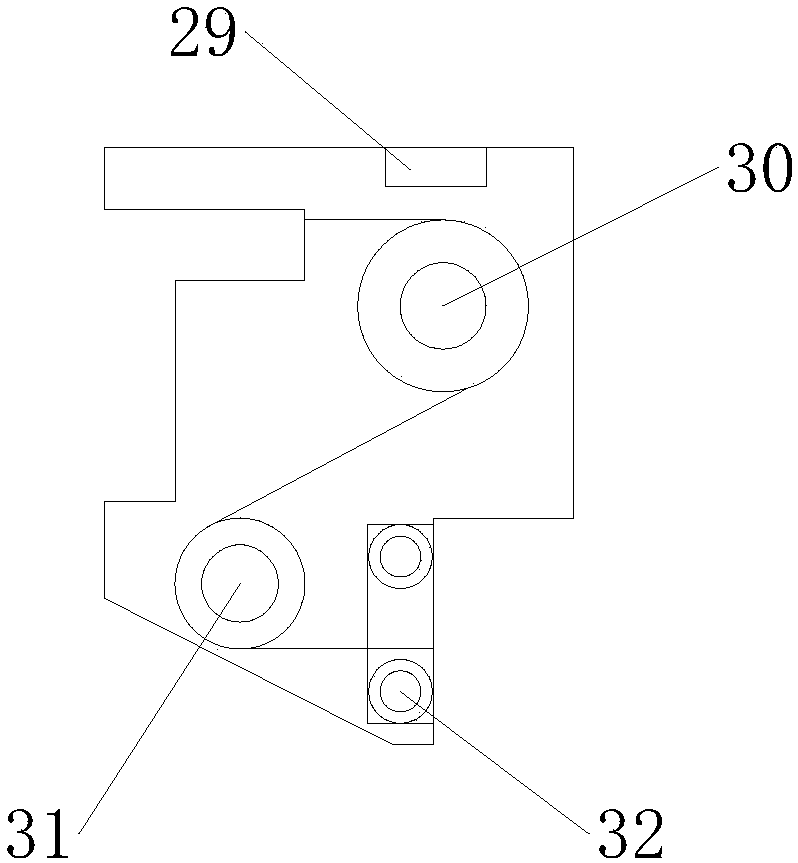

[0024] see Figure 1-3 The present invention discloses a mirror glue coating equipment for processing automobile rearview mirror heating sheets, comprising a casing 1, a base 6 and a Y2-160L motor 17, and the lower end of the casing 1 is welded with a base 6 The upper end of the casing 1 is fixedly connected with a Y2-160L motor 17, the middle part of the base 6 is embedded with a clamping plate 8, the right end of the clamping plate 8 is evenly arranged with conveying rollers 7, and the left end of the clamping plate 8 is tightly A LCDB2 type servo motor 9 is connected, and an LCDB2 type control panel 11 is embedded in the middle of the front of the casing 1. The input end of the LCDB2 type servo motor 9 is electrically connected to the output end of the LCDB2 type control panel 11, and the LCDB2 type The control panel 11 adjusts the working power of the LCDB2 type servo motor 9, and at the same time drives the conveying roller 7 to rotate through the servo motor 9 to complet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com