Cheese bobbin core with unwinding protection function

A protective function and package yarn technology, which is applied in the field of loom package yarn, can solve problems such as the influence of stoppage of weft insertion movement, package deformation, and edge wear of paper packages, so as to ensure the stability of process conditions, stable friction coefficient, The effect of preventing unwinding from being blocked

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

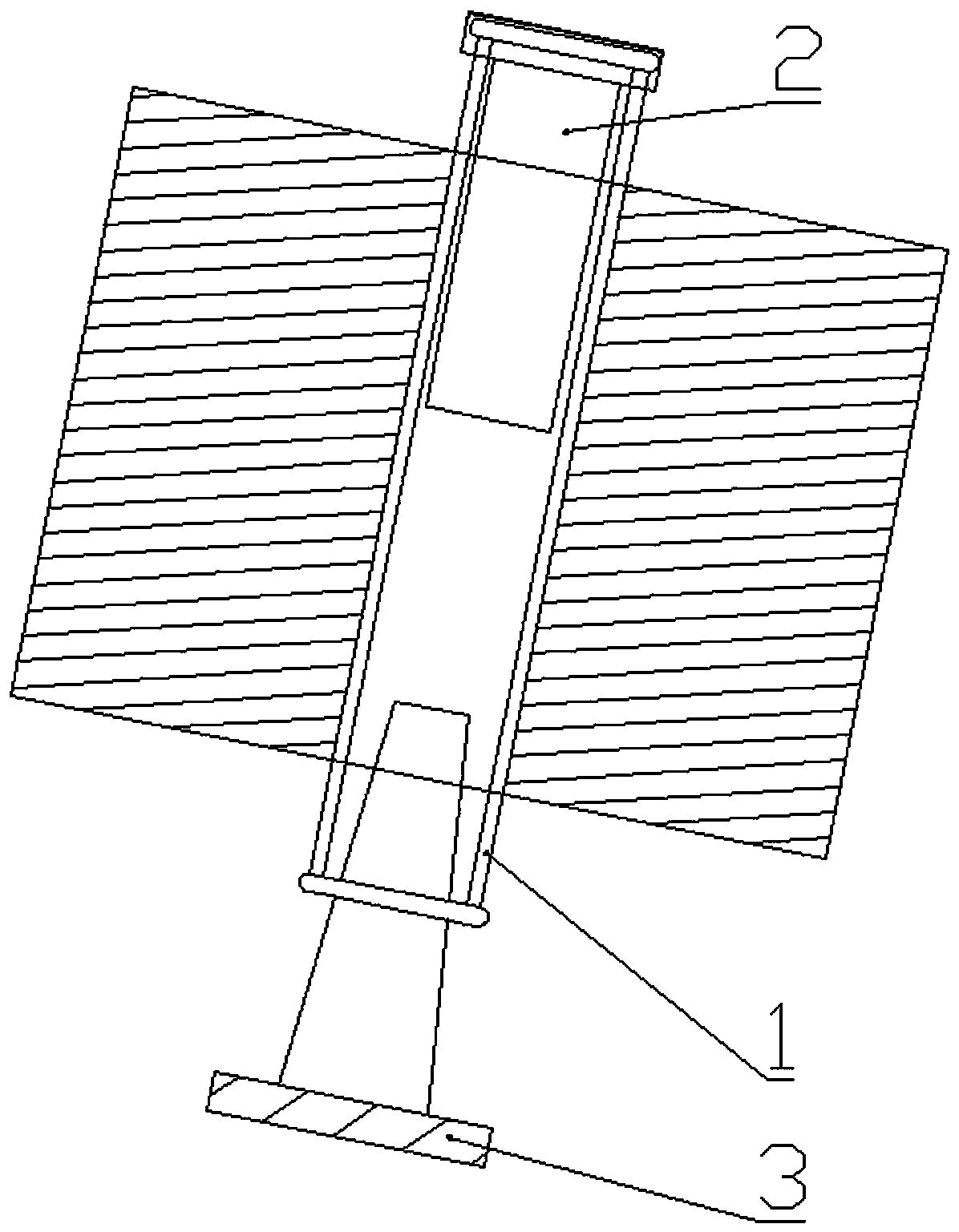

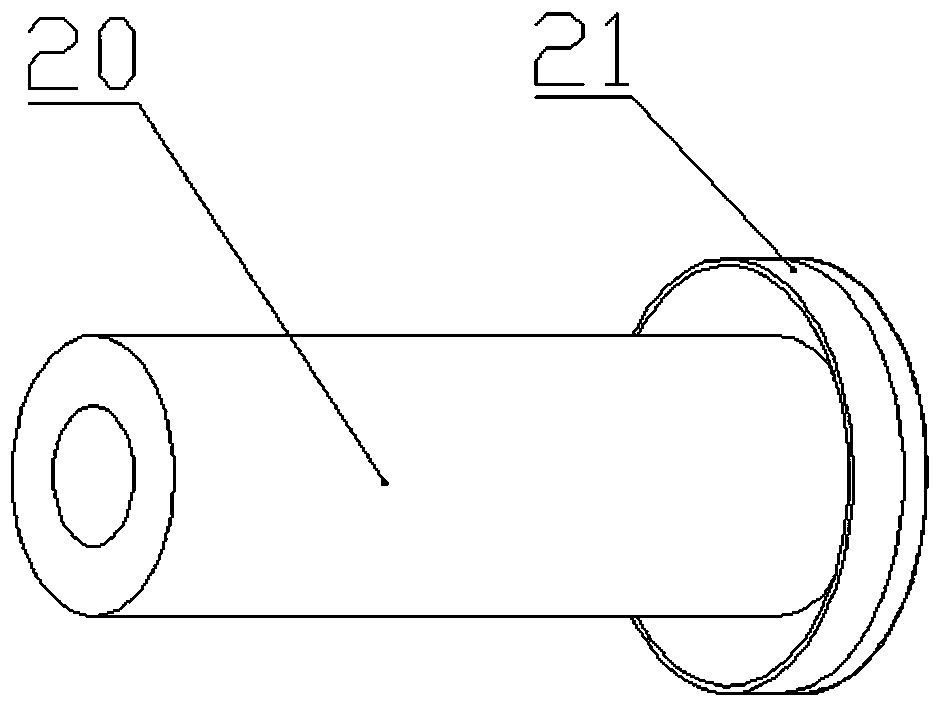

[0013] like figure 1 , figure 2 It can be seen that the cheese bobbin core with unwinding protection function in this embodiment includes a paper bobbin 1 and an unwinding protection device 2. The unwinding protection device 2 includes an inner cylinder 20 made of plastic. The top end of the inner cylinder 20 is provided with an end cap 21 made of stainless steel; the inner cylinder 20 is inserted into the inner cavity of the bobbin 1, and the two have an interference fit; the skirt of the end cap 21 covers the bobbin 1 top.

[0014] In this embodiment, the end cap 21 is made of stainless steel; the inner cylinder 20 is made of plastic.

[0015] The cheese bobbin core with unwinding protection function is installed on the core base 3 as a whole, and the weft thread is in contact with the skirt of the end cap 21 during the unwinding process. Since the end cap 21 is made of hard material, its wear resistance is far superior. Far better than hard paper, it can prevent unwindi...

Embodiment 2

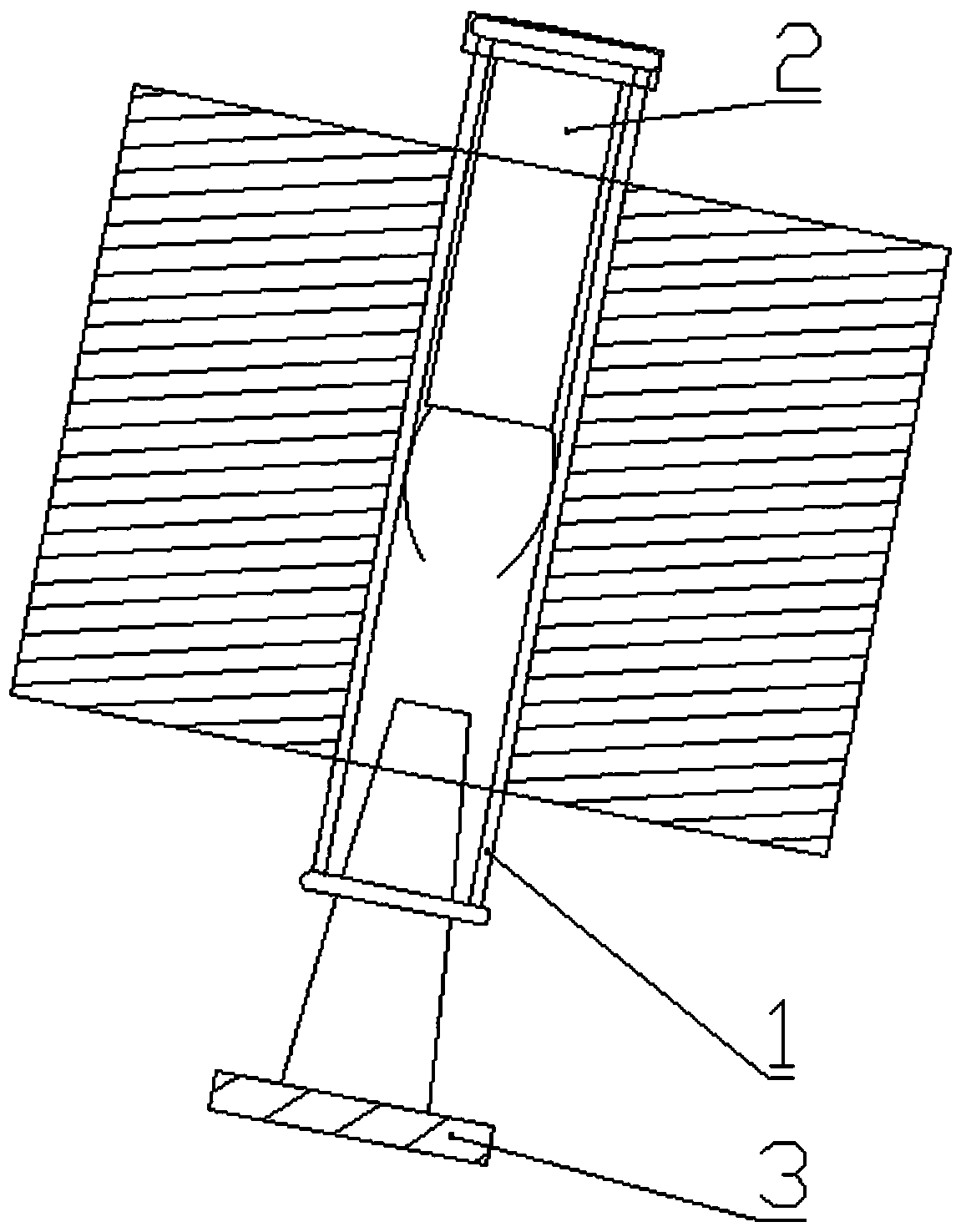

[0017] like image 3 , Figure 4 It can be seen that the bobbin core with unwinding protection function in this embodiment includes a paper bobbin 1, and is characterized in that it also includes an unwinding protection device 2, and the unwinding protection device 2 includes an inner cylinder made of plastic 20. The top end of the inner cylinder 20 is provided with a stainless steel end cap 21; the inner cylinder 20 is inserted into the inner cavity of the bobbin 1, and the two are interference fit; the skirt of the end cap 21 covers the The top of the bobbin 1 described above.

[0018] The bottom end of the inner cylinder 20 is provided with four spring pieces 22 along its length direction, and the spring pieces 22 are tensioned and arranged on the inner cylinder 20 . The spring piece 22 adopts an arc structure, and its protruding part is in contact with the inner wall of the inner cylinder 20 .

[0019] In the cross-sectional direction of the inner cylinder 20 , the four...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com