Method for improving compression forming rate of limestone mud cakes

A technology of pressing and forming limestone, which is applied in the field of steelmaking, can solve the problems of low utilization rate of converter sludge and ash, and achieve the effects of solving treatment costs, increasing pressing yield, and reducing dust emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

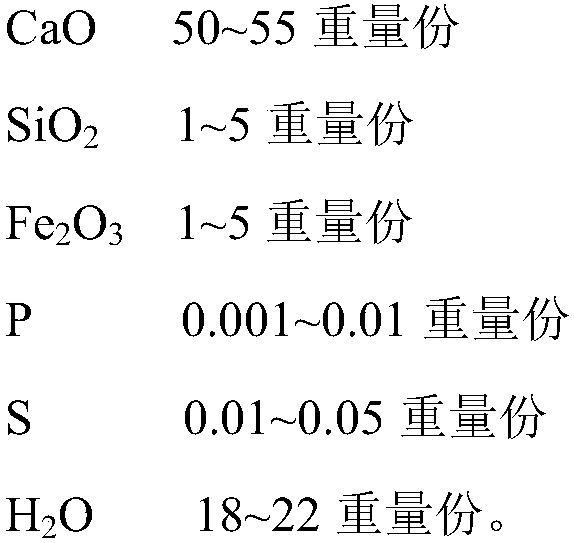

[0034] The limestone mud cake that adopts in the present embodiment comprises following raw material composition and weight part:

[0035]

[0036]

[0037] The method for improving limestone mud cake compression molding rate in the present embodiment may further comprise the steps:

[0038] Dry the limestone mud cake in the air to reduce the moisture content of the mud cake so that the mud cake changes from lumpy to powdery. During the drying process, add 5wt% quicklime to the limestone mud cake and stir evenly; after drying in the air, measure the moisture content 8wt%;

[0039] Pile and digest the dried limestone mud cake to form a digestion material for 2 hours to form a digestion material;

[0040] Pulverize and stir the digestion material to form a mixture; add binder water glass accounting for 5wt% of the digestion material in the form of spray during the pulverization and stirring process; if necessary for pulverization and stirring, you can also spray appropria...

Embodiment 2

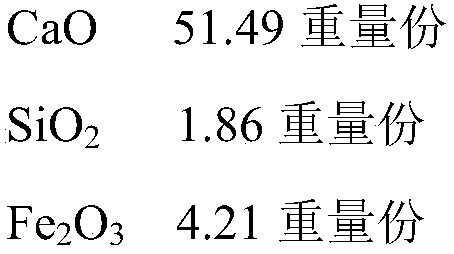

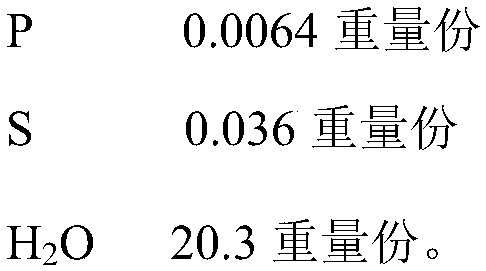

[0044] The limestone mud cake that adopts in the present embodiment comprises following raw material composition and weight part:

[0045]

[0046] The method for improving limestone mud cake compression molding rate in the present embodiment may further comprise the steps:

[0047] Dry the limestone mud cake in the air to reduce the moisture content of the mud cake so that the mud cake changes from lumpy to powdery. During the drying process, add 6wt% quicklime to the limestone mud cake and stir evenly; after drying in the air, measure the moisture content is 10wt%;

[0048] Pile and digest the dried limestone mud cake to form a digestion material for 3 hours to form a digestion material;

[0049] Pulverize and stir the digestion material to form a mixture; add binder water glass accounting for 6wt% of the digestion material in the form of spray during the pulverization and stirring process; if necessary for pulverization and stirring, appropriate water can also be spraye...

Embodiment 3

[0053] The limestone mud cake that adopts in the present embodiment comprises following raw material composition and weight part:

[0054]

[0055]

[0056] The method for improving limestone mud cake compression molding rate in the present embodiment may further comprise the steps:

[0057] Dry the limestone mud cake in the air to reduce the moisture content of the mud cake so that the mud cake changes from lumpy to powdery. During the drying process, add 7wt% quicklime to the limestone mud cake and stir evenly; after drying in the air, measure the moisture content 6wt%;

[0058] Pile and digest the dried limestone mud cake to form a digestion material for 3 hours to form a digestion material;

[0059] Pulverize and stir the digestion material to form a mixture; add binder water glass accounting for 8wt% of the digestion material in the form of spray during the pulverization and stirring process; if necessary for pulverization and stirring, appropriate water can also be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com