Patents

Literature

63results about How to "Promote green production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

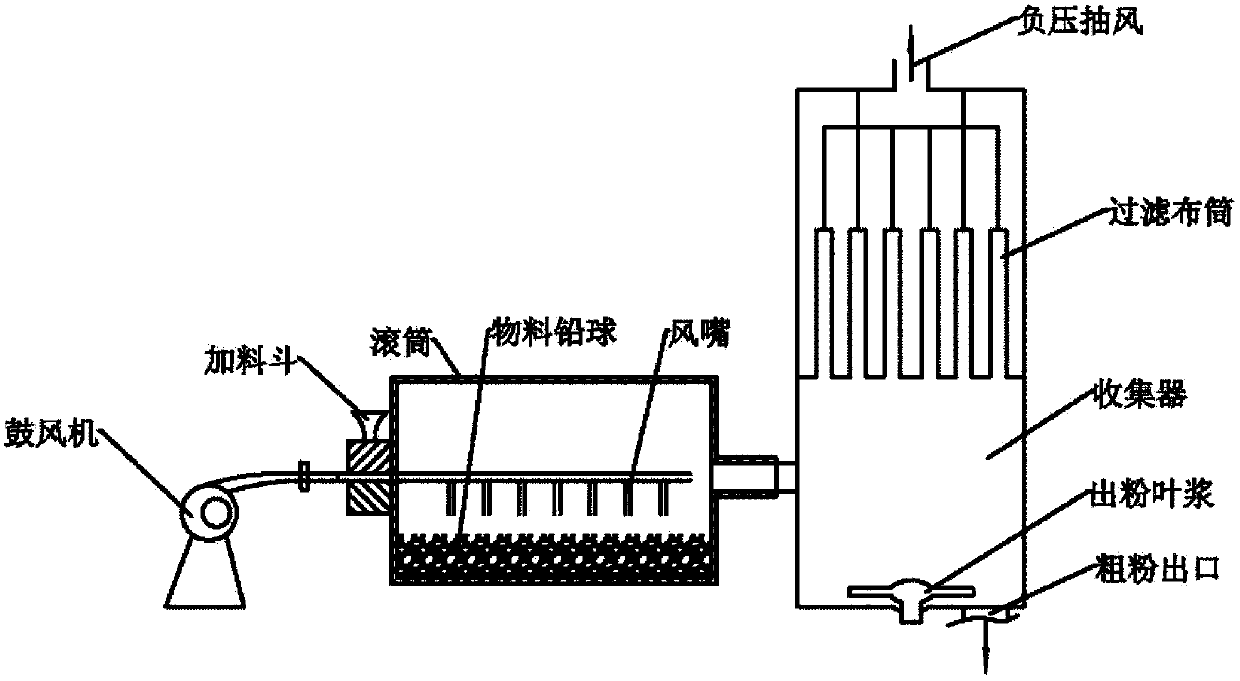

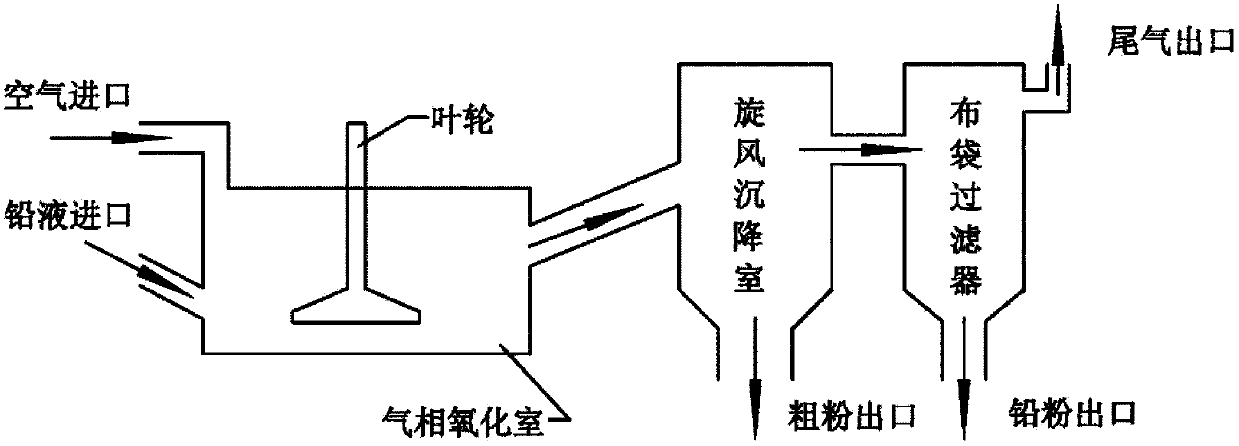

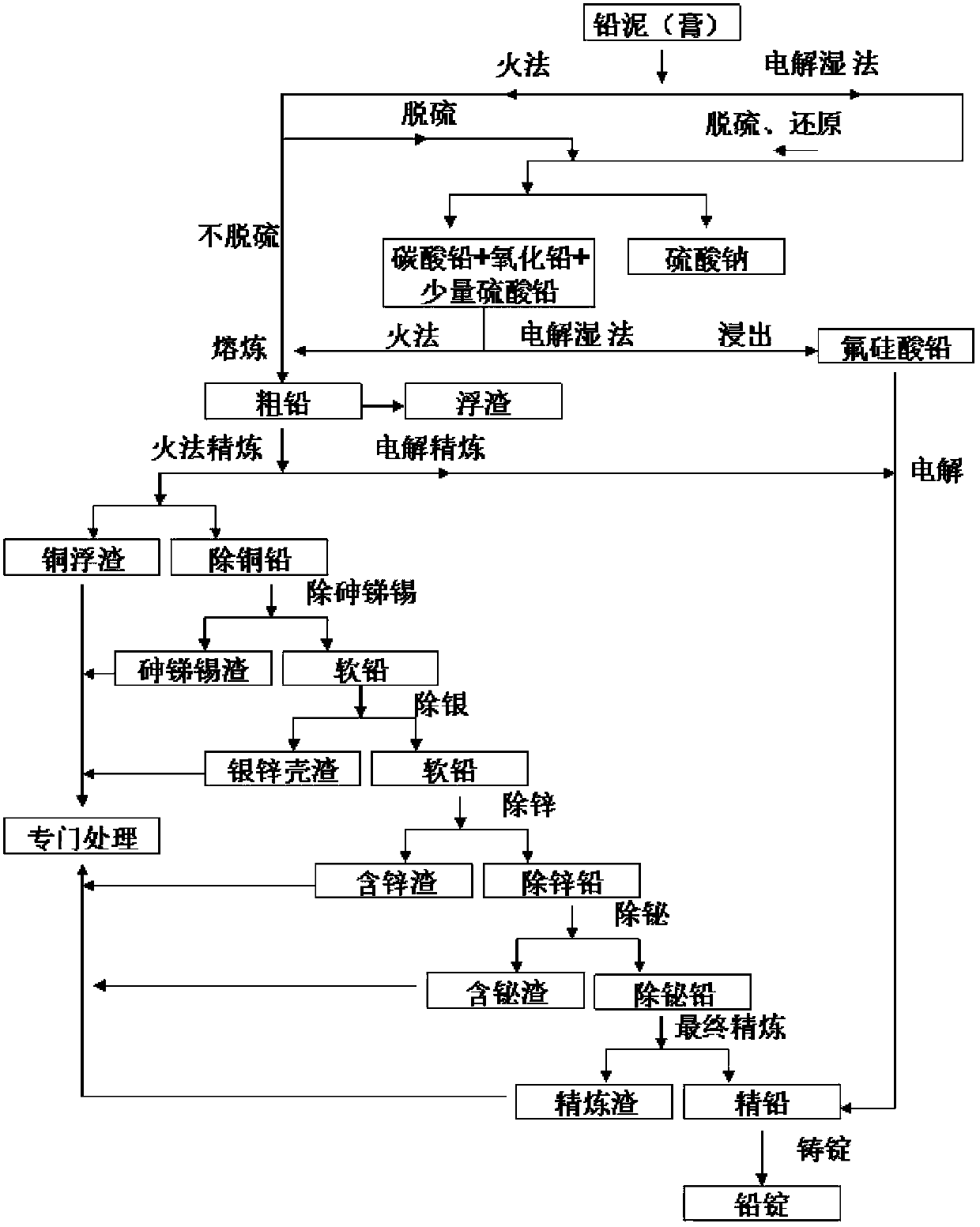

Methods and equipment for recovering waste diachylon by wet method and manufacturing electrode active material of high performance lead acid battery by wet method

ActiveCN103509949AIncrease profitLarge particle sizeWaste accumulators reclaimingProcess efficiency improvementElectrical batteryEngineering

The invention discloses methods and equipment for recovering waste diachylon by a wet method and manufacturing an electrode active substance material of a high performance lead acid battery by the wet method. The equipment comprises device required for a technology process by a chemical method, a chemical machinery method or an electrochemical machinery method. The active substance material provided by the invention can substantially raises an utilization rate of the active substance of the lead acid battery, specific energy of the battery and charging capability of the battery, simultaneously avoids generation and discharge of harmful substances such as lead gas, lead smoke, lead dust and SO2, raises a lead utilization rate in a production process, is beneficial for treating and recycling lead compounds and lead-containing liquid generated in a lead gas recovering process in a plate casting or welding technology, and reduces cost.

Owner:杨春晓

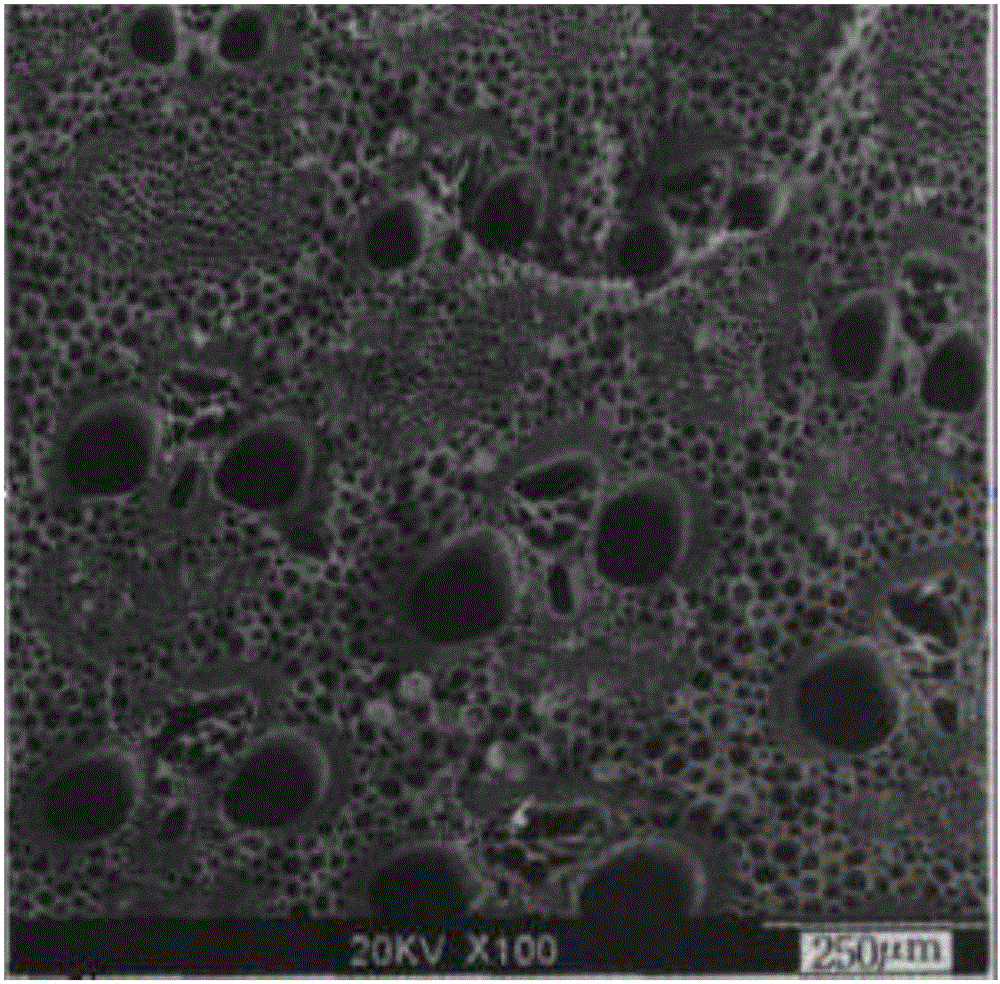

Preparation method of micro-spherical aerogel based on super-hydrophobic surface, product obtained by using method and application of method

The invention discloses a preparation method of micro-spherical aerogel based on a super-hydrophobic surface, a product prepared by using the method and application of the method. The preparation method of the micro-spherical aerogel comprises the following steps: forming small spheres on the super-hydrophobic surface by using a silica gel aqueous solution; further gelling to form wet gel; carrying out a series of procedures of aging, solvent displacement, surface medication and drying. By adopting the preparation method, the preparation cost and period of the micro-spherical aerogel are lowered and shortened greatly, and the applicability of the aerogel is improved.

Owner:GUANGZHOU UNIVERSITY

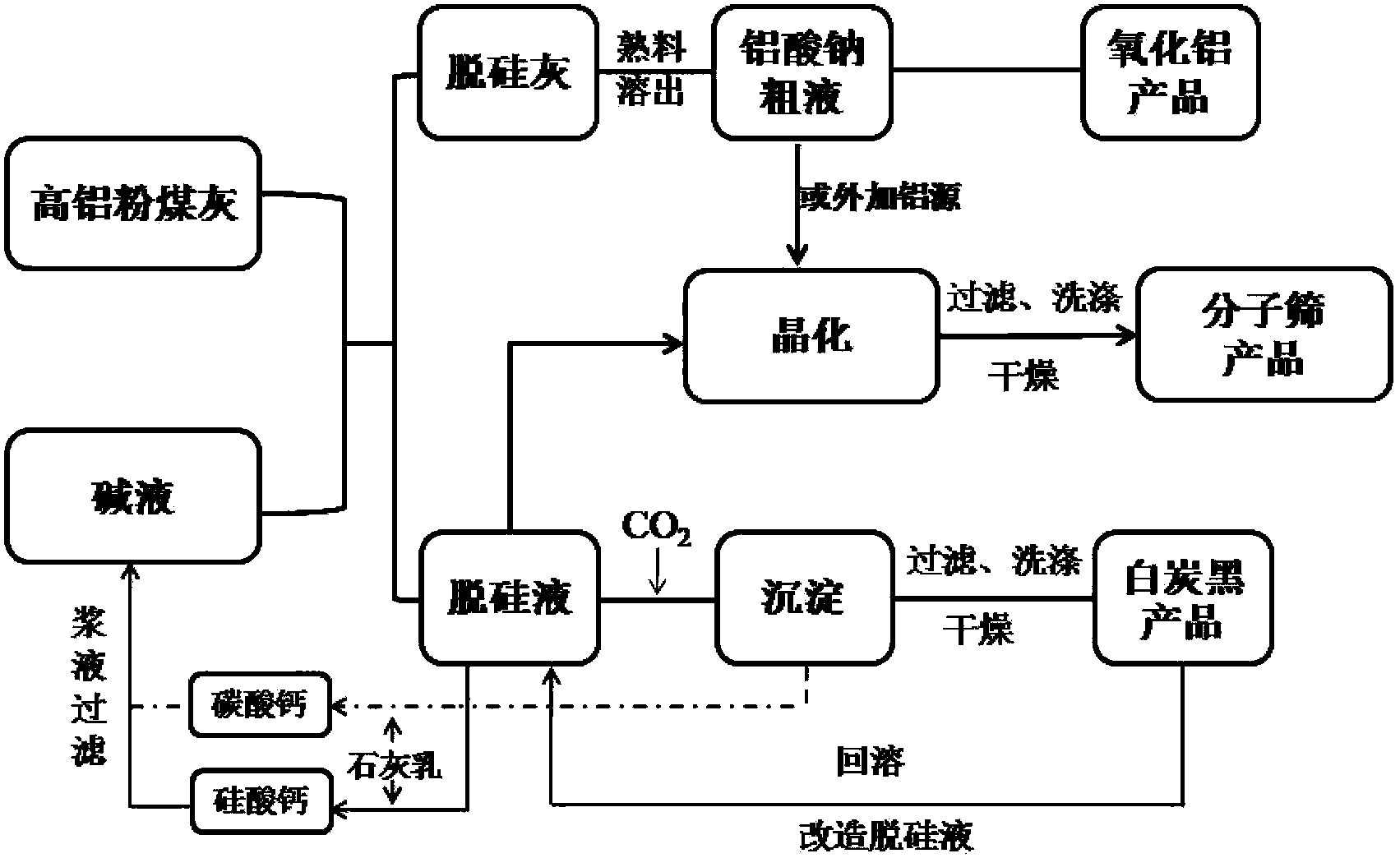

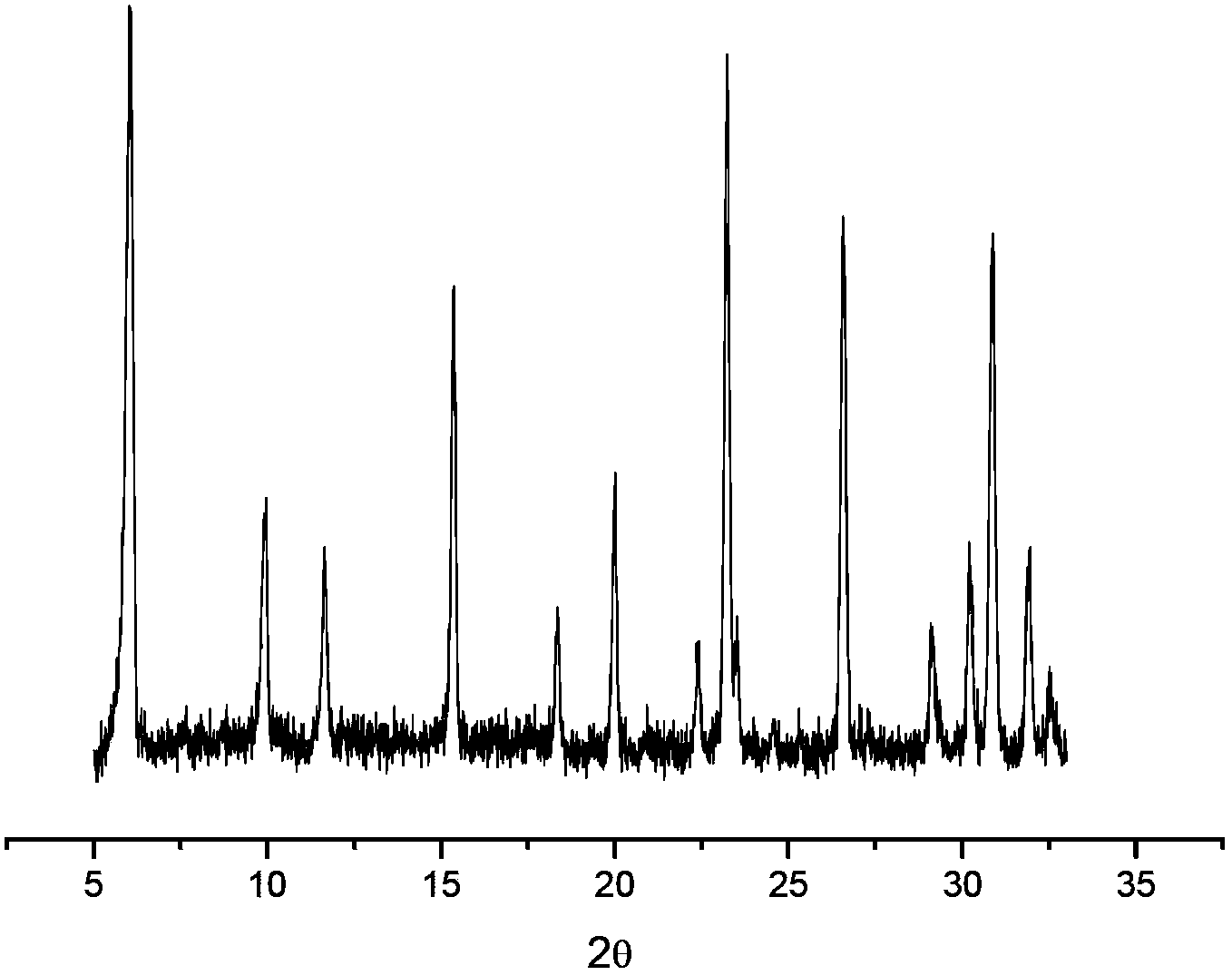

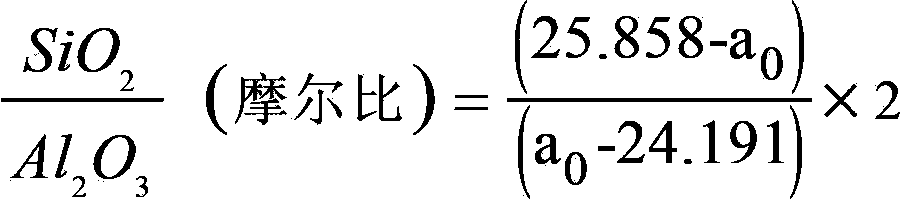

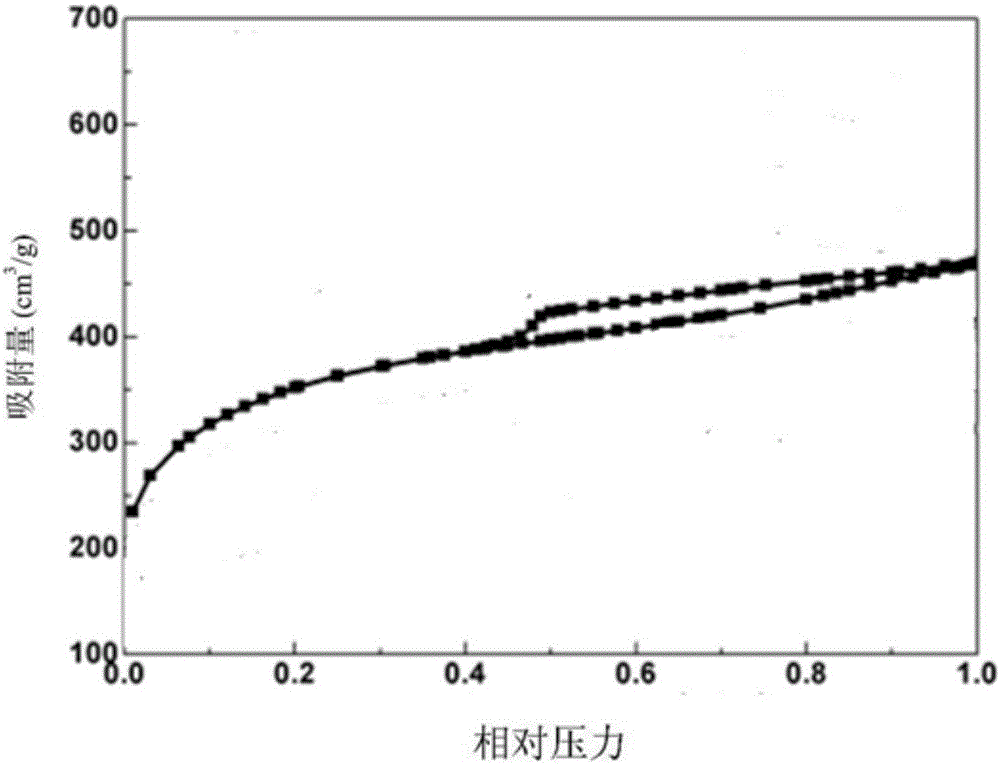

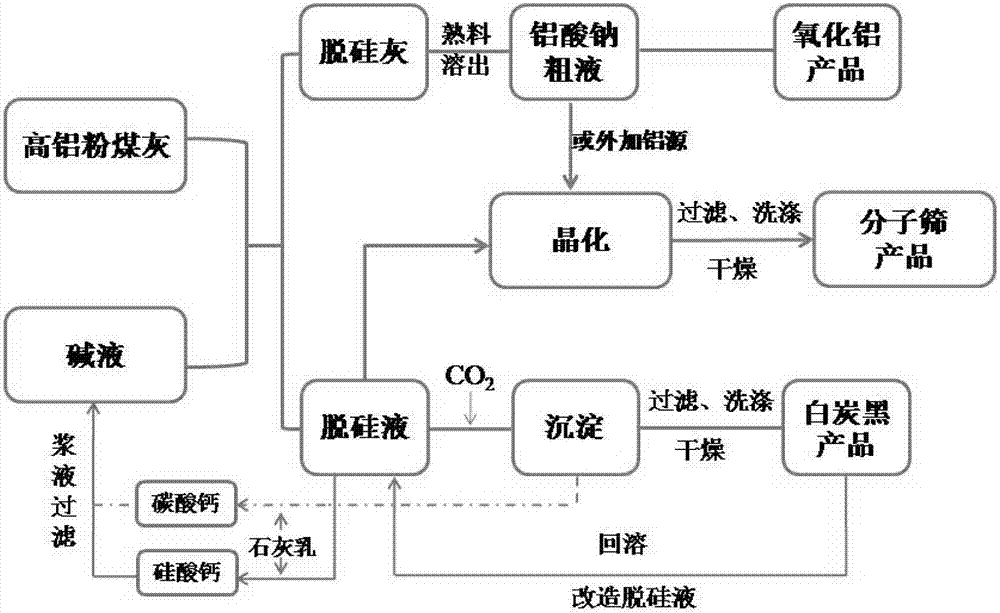

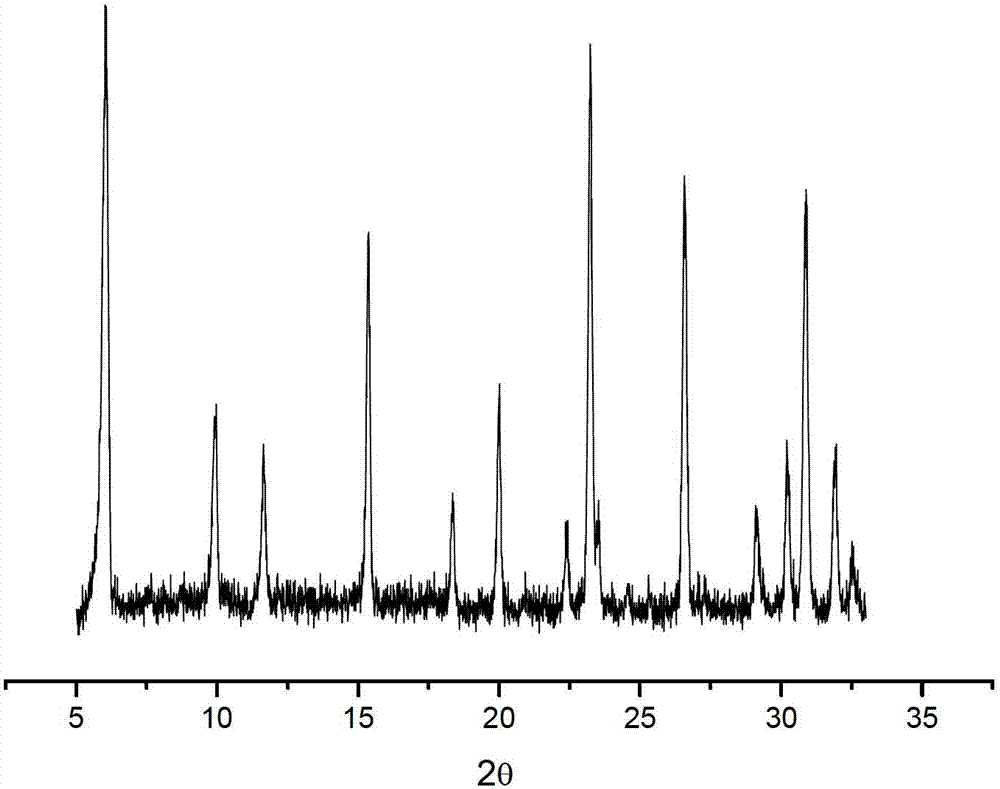

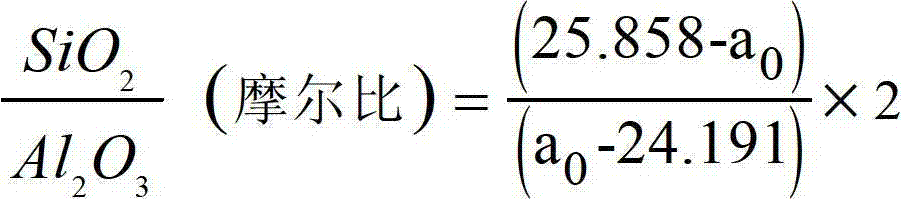

Method for preparing 13X molecular sieve through using high-alumina fly ash, and 13X molecular sieve

InactiveCN103449467ALow costAchieve environmental protectionSolid waste disposalFaujasite aluminosilicate zeoliteMolecular sieveFly ash

The invention provides a method for preparing a 13X molecular sieve through using high-alumina fly ash, and the 13X molecular sieve. The preparation method comprises the following steps: mixing the high-alumina fly ash with an alkali solution for a pre-desiliconization reaction, and filtering to obtain a desiliconized solution; mixing the desiliconized solution with white carbon black to obtain a modified desiliconized solution; mixing the modified desiliconized solution with an aluminum sauce to obtain a silicon and aluminum sol; and crystallizing the silicon and aluminum sol, filtering, washing, and drying to prepare the 13X molecular sieve. The invention also provides the 13X molecular sieve prepared through the preparation method.

Owner:DATANG INT CHEM TECH RESINST

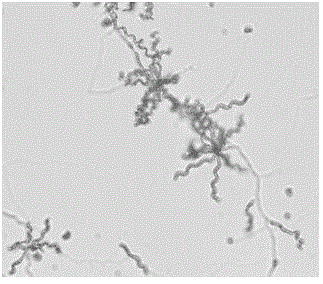

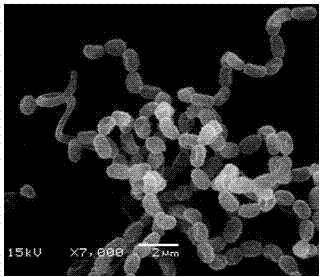

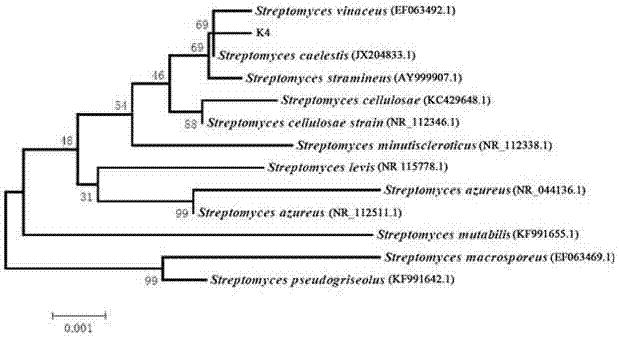

Biocontrol actinomycete strain for preventing and controlling tobacco bacterial wilt and application thereof

The invention discloses a biocontrol actinomycete strain for preventing and controlling tobacco bacterial wilt and application method thereof and belongs to the technical field of micro-organisms. The strain is streptomyces K4, is collected in China General Microbiological Culture Collection Center on March 24, 2014 and has the collection number of CGMCC No. 8949. The strain generates active substances to inhibit the growth of tobacco bacterial wilt and exhibits better prevention and control effects on the tobacco bacterial wilt. The biocontrol actinomycete strain is used for preparing a biocontrol microbial agent and the biocontrol microbial agent can be applied together with rooting water when tobacco seedlings are transplanted; or the biocontrol microbial agent is irrigated into the roots at 4-5 days after the tobacco seedlings are transplanted. The microbial agent can be applied as a bacterial fertilizer prepared by mixing the microbial agent and an organic fertilizer. The strain K4 is obtained from tobacco field rhizosphere soil and is ecologically and harmoniously compatible with soil so that the strain K4 has good application prospects in the biological control of tobacco bacterial wilt.

Owner:INST OF PLANT PROTECTION FAAS

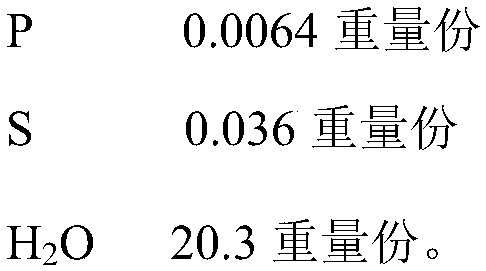

Inorganic high performance fiber composite material and preparation method thereof

The invention discloses an inorganic high performance fiber composite material, prepared from the following raw materials in parts by weight: 450-900 parts of cement with the mean grain size of 30-60 mu. m and strength grade not less than 42.5, 180-360 parts of active mineral admixture with the mean grain size of 0.1-60 mu. m, loss on ignition being less than or equal to 3.0 percent, and a 28-day activity index not lower than 90 percent, 70-120 parts of inert admixture with the mean grain size of 0.1-60 mu. m, 850-1250 parts of sand with the continuous grading grain size of 0.16-4.75mm, 25-32 parts of water reducer with a water reducing rate greater than 30 percent, 130-150 parts of water, and 50-120 parts of copper plating end hook-shape steel fiber with the diameter less than 0.20mm and length of 12-14mm. The composite material is relatively low in overall price, uniform in fiber distribution, high in compressive strength and flexural strength, good in tenacity and suitable for being popularized and used in the constructional engineering industry.

Owner:黄贺明

Preparation method of methyltrialkoxysilane

InactiveCN104262380AImprove efficiencyHigh yieldGroup 4/14 element organic compoundsAmmonium halidesAlcoholMethyltrichlorosilane

The invention provides a preparation method of methyltrialkoxysilane. The preparation method comprises the following steps of adding anhydrous alcohol into a reaction container A, arranging one end of a gas-guide tube under the liquid level in the reaction container A, introducing the other end of the gas-guide tube into a container B with methyltrichlorosilane, heating the anhydrous alcohol in the reaction container A to a temperature of 55-63 DEG C for a reaction, heating the methyltrichlorosilane in the container B to a temperature of 62-68 DEG C, feeding N2 into the container B, heating the mixed solution in the reaction container A to a temperature of 75-88 DEG C, carrying out a backflow thermal-insulation reaction process for 1-4h, then stopping heating, collecting the product, and feeding ammonia gas into the product to adjust product pH to 8-9 so that methyltrialkoxysilane is obtained. Dry neutral gas and an ammonia gas neutralizer are used under the conditions of normal pressure and low temperature. The preparation method utilizes simple technical equipment, is convenient for operation, and has a low cost and a high yield. Ammonium chloride obtained by neutralization of the preparation method can be used as fertilizer and is conducive to green production.

Owner:HUBEI XINGFA CHEM GRP CO LTD

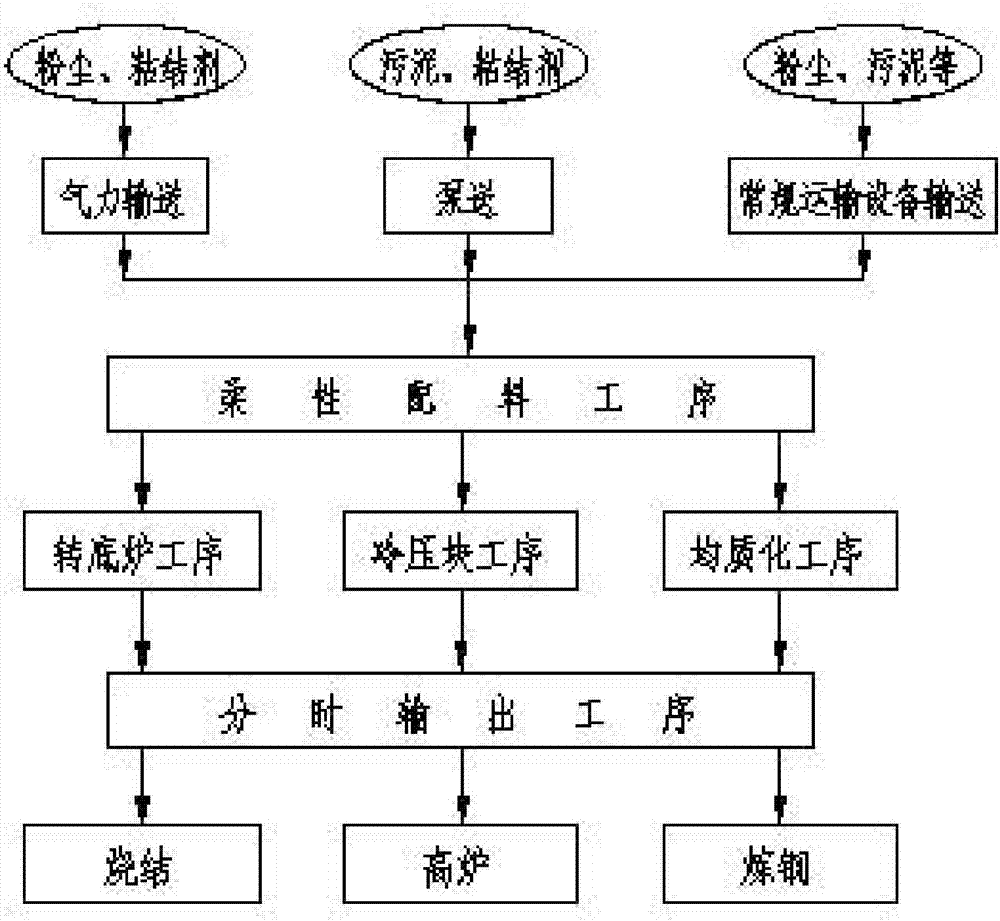

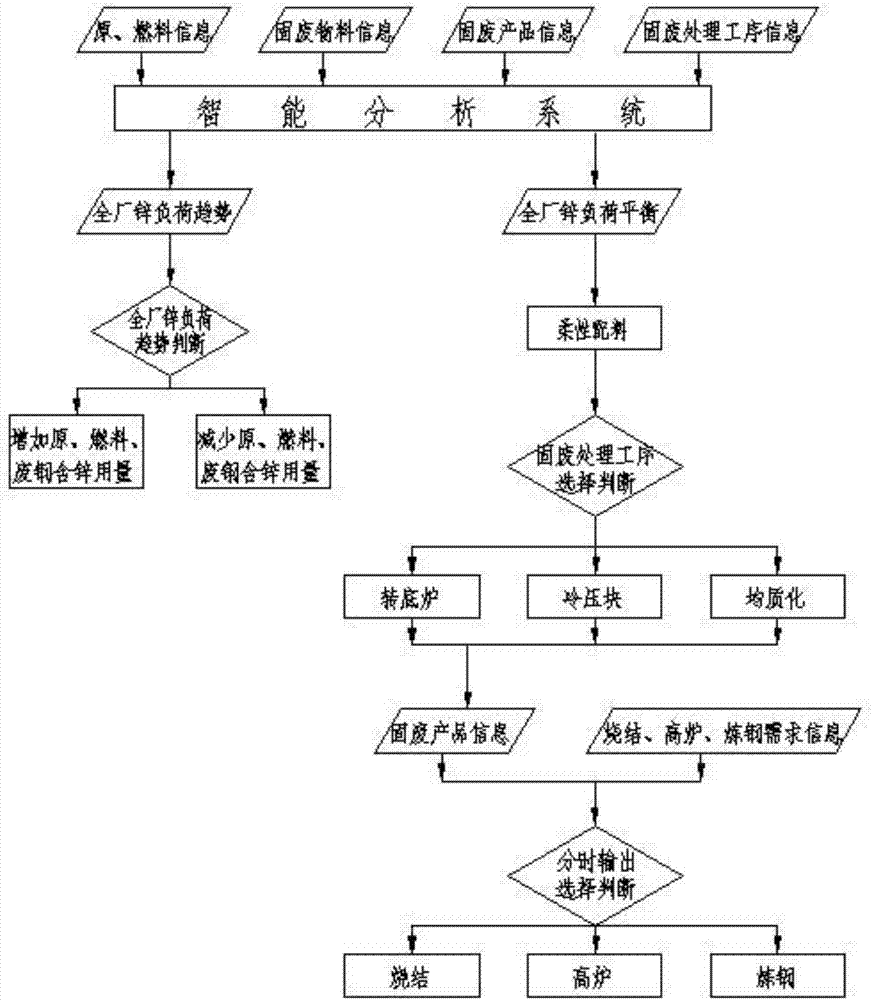

Iron-contained solid waste intelligent treatment system and control method thereof

ActiveCN107385201AIncrease usageReduce the burden of converter desulfurizationBlast furnace detailsManufacturing convertersFlexible dosingWaste product

The invention belongs to the field of metallurgy, and relates to an iron-contained solid waste intelligent treatment system and a control method thereof. A flexible dosing process, a homogenizing process, a cold briquetting process, a rotary hearth furnace process and a time dividing output process are included; intelligent matching is carried out according to the iron, zinc and sulphur content conditions of iron-contained solid waste and states of all processes, the flexible dosing process is responsible for dosing, the homogenizing process, the cold briquetting process and the rotary hearth furnace process are responsible for treatment, and the time dividing output process is responsible for conveying materials to sintering, blast furnace and converter zones; and according to crude fuel information, solid waste generation information, solid waste product need information originally utilized by an iron and steel plant, the zinc load of the iron and steel plant is comprehensively forecasted, the supplying amount of high zinc-contained ore and high zinc-contained waste steel of the iron and steel plant is directed, the using amount of low-price high zinc-contained materials is increased, the sulphur content of solid waste product used by a converter is reduced, the converter desulfuration load is reduced, the using depth of iron-contained solid waste resources of the iron and steel plant is improved, the green production of the iron and steel industry is effectively pushed, and efficient and recycling circulated utilization of a iron-contained solid waste plant is achieved.

Owner:CHONGQING CISDI THERMAL & ENVIRONMENTAL ENG CO LTD

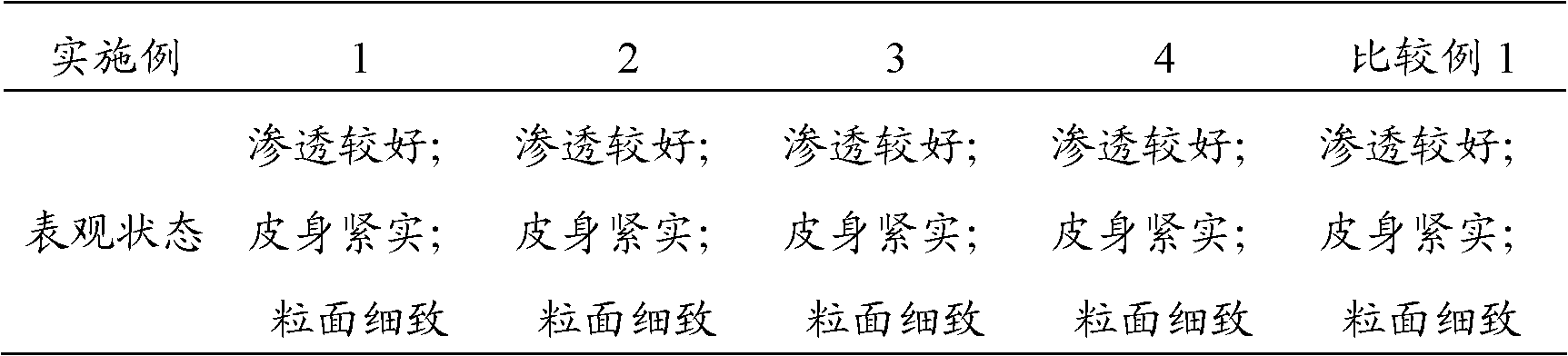

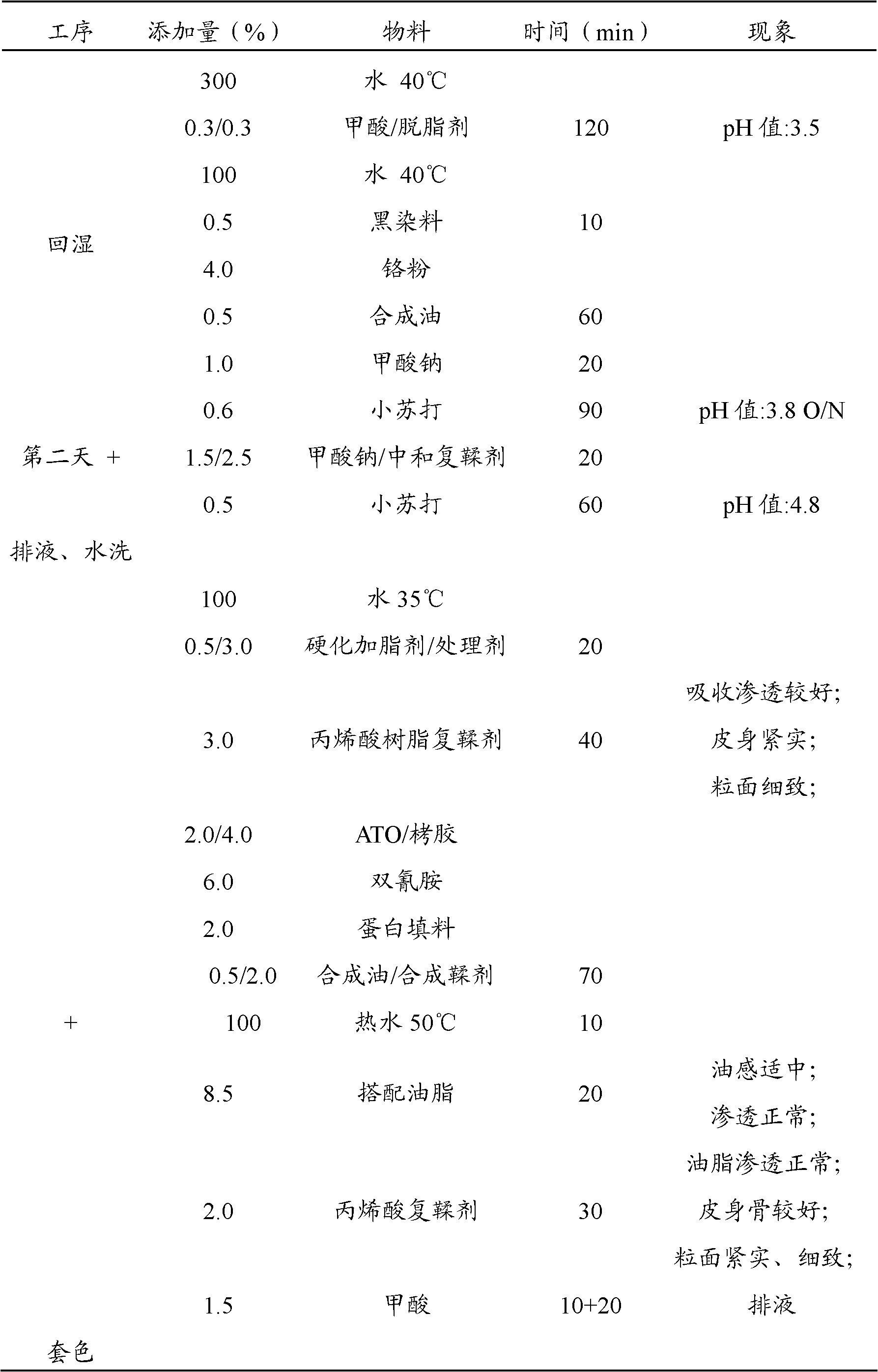

Acrylic resin retanning agent and preparation method thereof

ActiveCN102516444AGood filling performance and convergence performanceImprove firmnessTanning treatmentDyeingColor loss

The invention provides an acrylic resin retanning agent, which is obtained by polymerization of the following raw materials in water: crylic acid or methacrylic acid; methacryloyloxyethyl trimethyl ammonium chloride; acetoacetate ethyl methacrylate; chain regulator; catalytic agent and initiator. The invention also provides a preparation method of the acrylic resin retanning agent. According to the method, polymerization of acrylic monomers can be initiated at low temperature, so that the stability of a reaction system in a feeding period is easy to control, the reaction is stable, the energyconsumption can be saved, and the green production is favored. The acrylic resin retanning agent provided by the invention has favorable filling performance and convergence performance, the compactibility of hide fiber can be improved, the color loss can be avoided, the absorption of dye and fatliquor is favored, the absorption rate is improved, the waste water emission is reduced, and the effects of dyeing and fatliquoring are improved.

Owner:SICHUAN DOWELL SCI & TECH INC

Method for recycling sand mold casting waste sand

InactiveCN110586855AThe production process is compact and reasonableLess waste waterMould handling/dressing devicesEconomic benefitsWastewater

The invention relates to the technical field of sand mold casting and in particular to a method for recycling sand mold casting waste sand. The method comprises the specific steps that caked waste sand on a sieve is broken into fine sand; then, the fine sand and an acid solution are mixed sufficiently through spraying; the fine sand mixed sufficiently is ground through a grinding machine; separation is carried out through a centrifugal machine, solids obtained through centrifugal processing are dried until the moisture content is equal to or lower than 0.5-1%; and the dried fine sand is subjected to air screening and magnetic screening to remove impurities in the fine sand, and a finished product is obtained. By means of the method, emission of waste water and waste gas in the production process is reduced, waste sand is recycled, and economic benefits are improved.

Owner:山西永益铸管股份有限公司

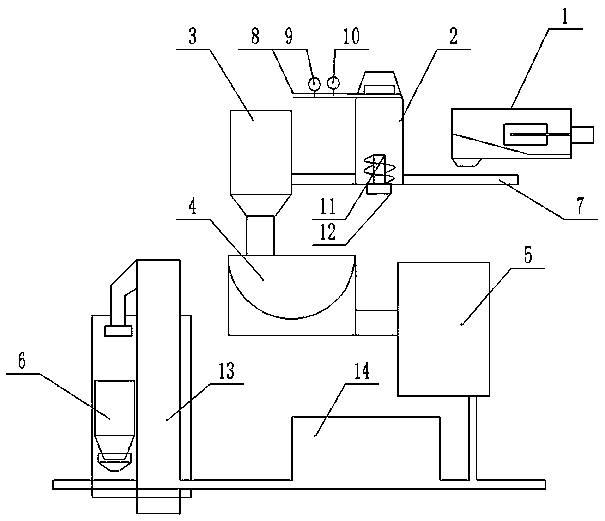

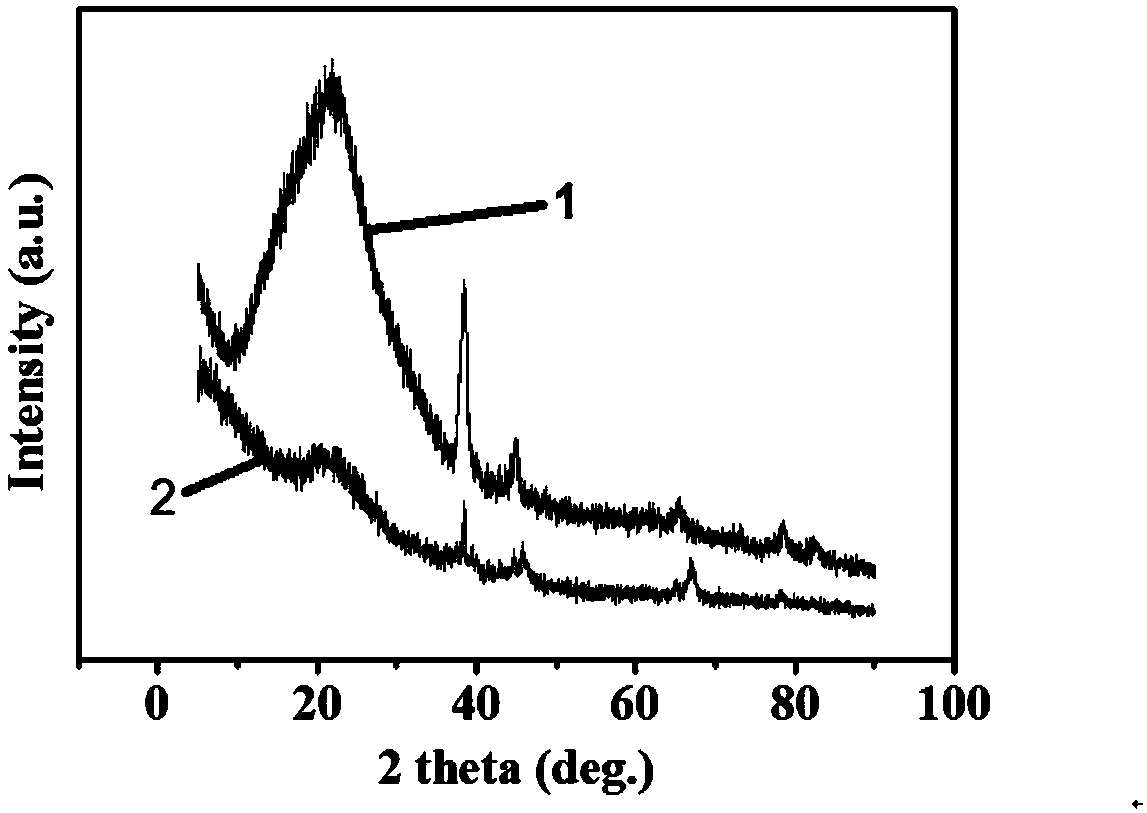

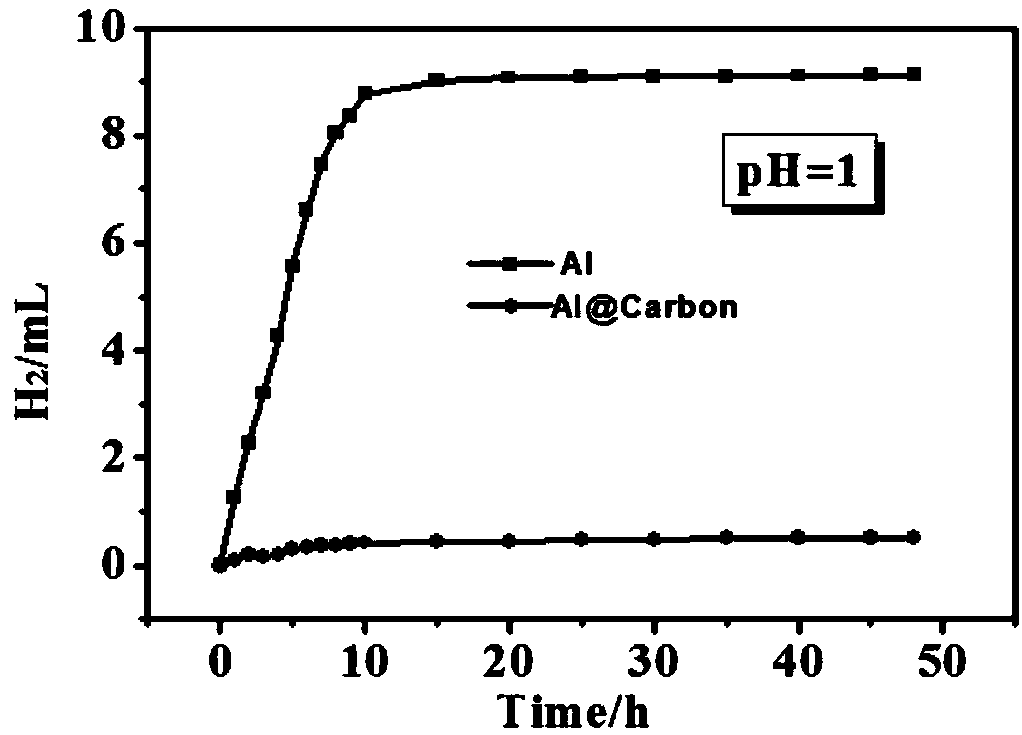

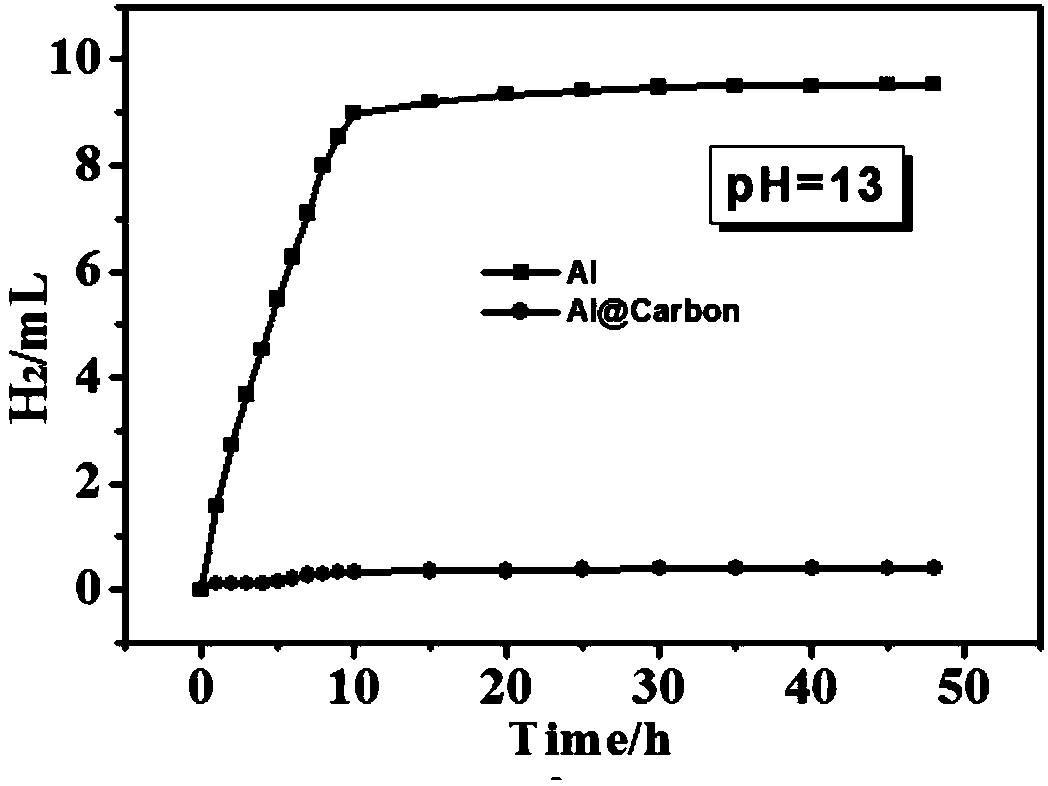

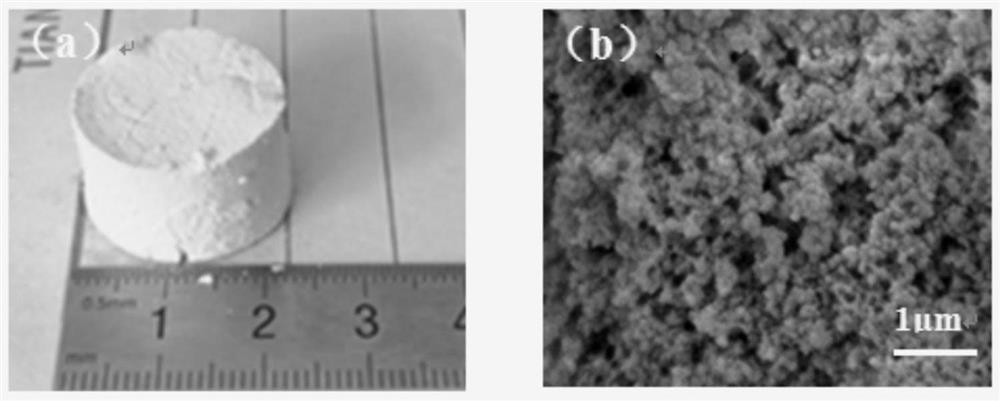

Acid and alkaline resistant micro-nano aluminum powder/porous carbon composite material and synthesis method thereof

The invention discloses an acid and alkaline resistant micro-nano aluminum powder / porous carbon composite material and a synthesis method thereof. The method is mainly characterized in that a composite solvent system is firstly designed to dissolve a carbon precursor and disperse an aluminum powder raw material; 30-50 parts by weight of the composite solvent system are added with the following materials in parts by weight: 30-40 parts of micro-nano aluminum powder and 20-30 parts of a carbon source. The invention further discloses a preparation method for the material, and the material is lessin organic substance volatile matter content, is beneficial for environmental protection, has good acid and alkaline resistance and good wear resistance, is long in service life, is good in storage stability, is simple to operate, and is suitable for large-scale industrial production.

Owner:ANHUI AOYA ALLOY +1

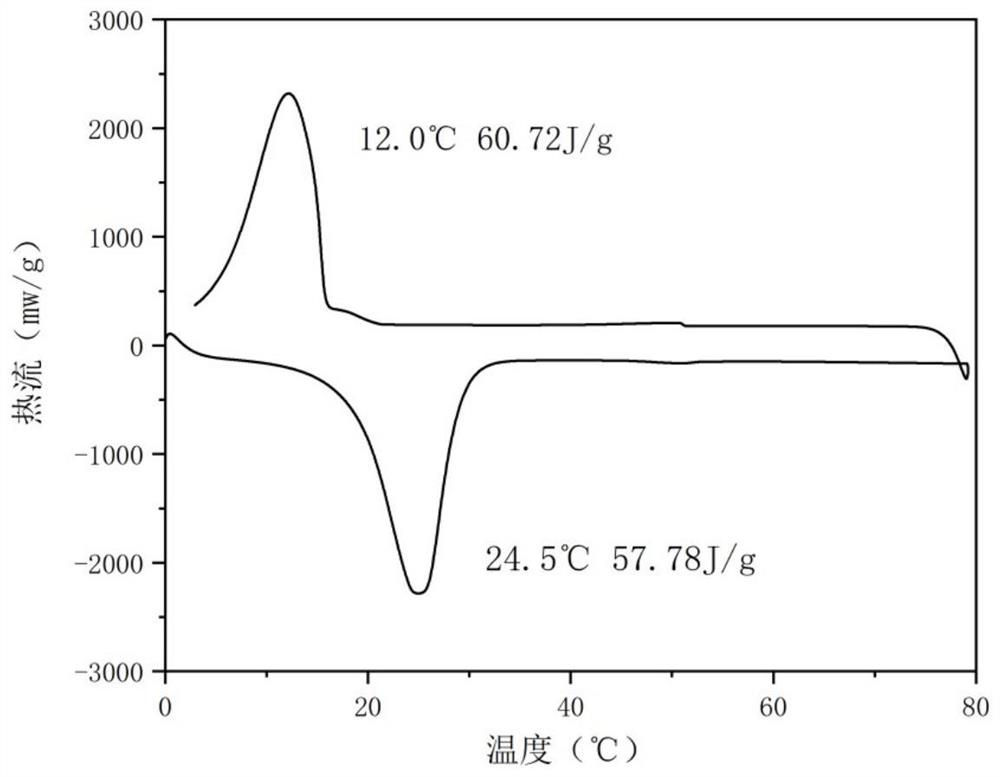

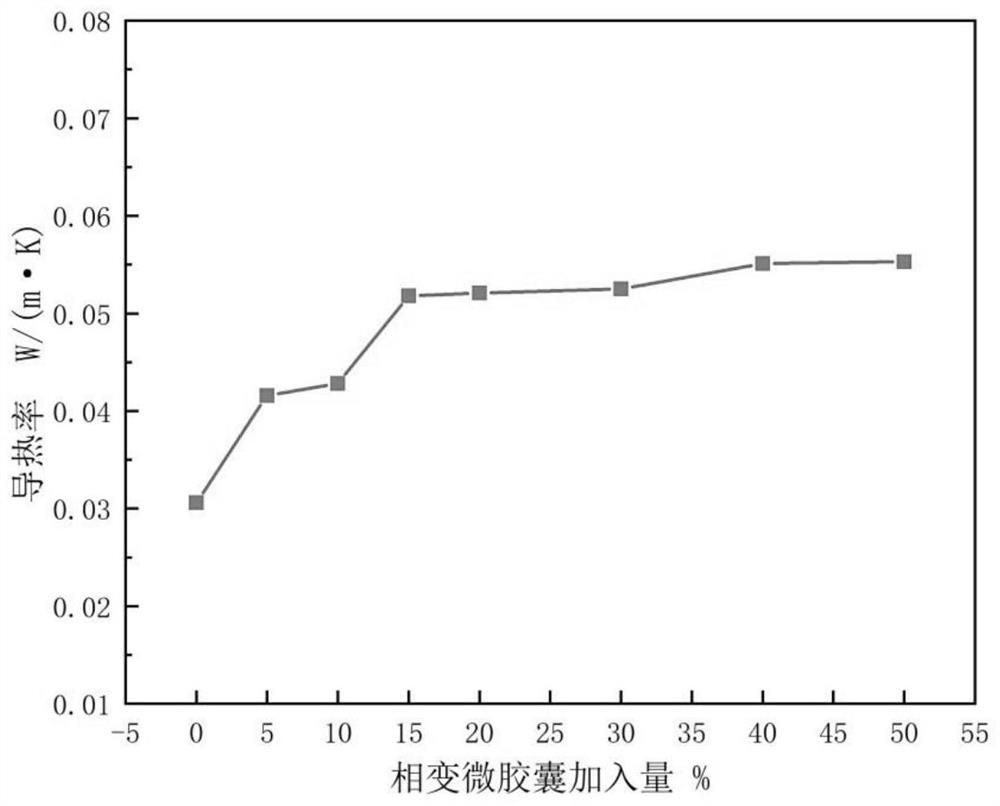

Phase-change composite aerogel and preparation method thereof

The invention provides a phase-change composite aerogel and a preparation method thereof. The preparation method comprises the steps of: mixing a silicon source 1 and a silicon source 2 and then dissolving the mixture in an aqueous solution of ethyl alcohol, performing mechanical stirring at room temperature till uniform mixing, then adding an acid catalyst into dispersion liquid, and adjusting the pH of the dispersion liquid to be 1-3, thus obtaining a silicon dioxide sol; adding a basic catalyst into the silicon dioxide sol prepared in the step 1, adjusting the pH value of the silicon dioxide sol to 7-10, adding phase-change microcapsules and fibers into the sol, performing mechanical stirring at room temperature until the materials are uniformly mixed, pouring the mixed sol into a mold,conducting standing to obtain wet gel, removing the wet gel from the mold, performing soaking in an anhydrous ethanol solution, performing aging for 10-40h, and finally conducting drying at 25-65DEGC for 20-30h to obtain the phase-change composite aerogel. The phase-change microcapsules are loaded in the silicon dioxide aerogel, and the nanofibers with good heat-conducting property are added toenhance the heat-conducting property of the aerogel skeleton, so that the phase-change microcapsules and the silicon dioxide aerogel are optimized.

Owner:TIANJIN CHENGJIAN UNIV

Density-increasing nitrogen-reducing efficient planting method for spring corn mixed cropping leguminous green manure

InactiveCN112970535AEfficient productionImprove basal fertilityFabaceae cultivationCereal cultivationSoil scienceGreen manure

The invention discloses a density-increasing nitrogen-reducing efficient planting method for spring corn mixed cropping leguminous green manure, and belongs to the field of crop planting. According to the method, corn and leguminous green manure are mixed for cropping, so that the planting density is moderately improved, the input of a nitrogen fertilizer and a pesticide is reduced, the purpose of high yield and high efficiency of the corn is achieved, and powerful technical support can be provided for efficient production and green production of the corn.

Owner:HUAZHONG AGRI UNIV

Method for separating acetone and methanol mixture

InactiveCN102190558ASimple craftEasy to operateOrganic compound preparationHydroxy compound preparationTheoretical plateDistillation

The invention discloses a method for separating an acetone and methanol mixture, relating to the technical field of extraction and distillation. In the invention, a fifteen plate in an extractive rectifying tower with the theoretical tower number of 45 is used as a feeding plate, and a water solution of sodium chloride or potassium chloride is introduced by the connection of the feeding plate; when the reflow ratio of the tower top of the extractive rectifying tower is 4:1, a distillate with the temperature of 56-56.5DEG C, which is collected at the tower top, is acetone; a distillation tower is continuously heated; and a distillate with the temperature of over 56.5DEG C, which is collected at the tower top, is methanol. The method disclosed by the invention can be realized just by distillation-extraction and can be operated at normal temperature and normal pressure; an extracting agent is free from recovery; the method adopts simple equipment and a simple process, has favorable separation effect and is convenient to operate; the respectively-obtained acetone has the mass fraction being capable of reaching 99.5 percent, does not contain the methanol and only contains water with less than 5 percent; and the mass fraction of the obtained methanol can also reach 99.5 percent.

Owner:YANGZHOU LIBANG CHEM

Curculio chinensis chevrolat attractant and attractant attraction core making method

The invention discloses a curculio chinensis chevrolat attractant and an attractant attraction core making method. The attractant is composed of at least five of six substances including cis-3-hexene-1-alcohol, cis-2-hexenyl acetate, 3-heptanone, hexanal, nonanal and hexadecanoic acid according to a volume ratio of 0-10:0-40:0-10:0-20:0-30:0-40.The making method includes: dripping a dichloromethane solution containing the attractant into a latex plug, and naturally volatilizing to obtain the attractant, wherein the attractant can be volatilized and released slowly and stably. The attractant isnontoxic, harmless and free of environment pollution and has good attraction effect on curculio chinensis chevrolat.

Owner:云南省林业科学院油茶研究所

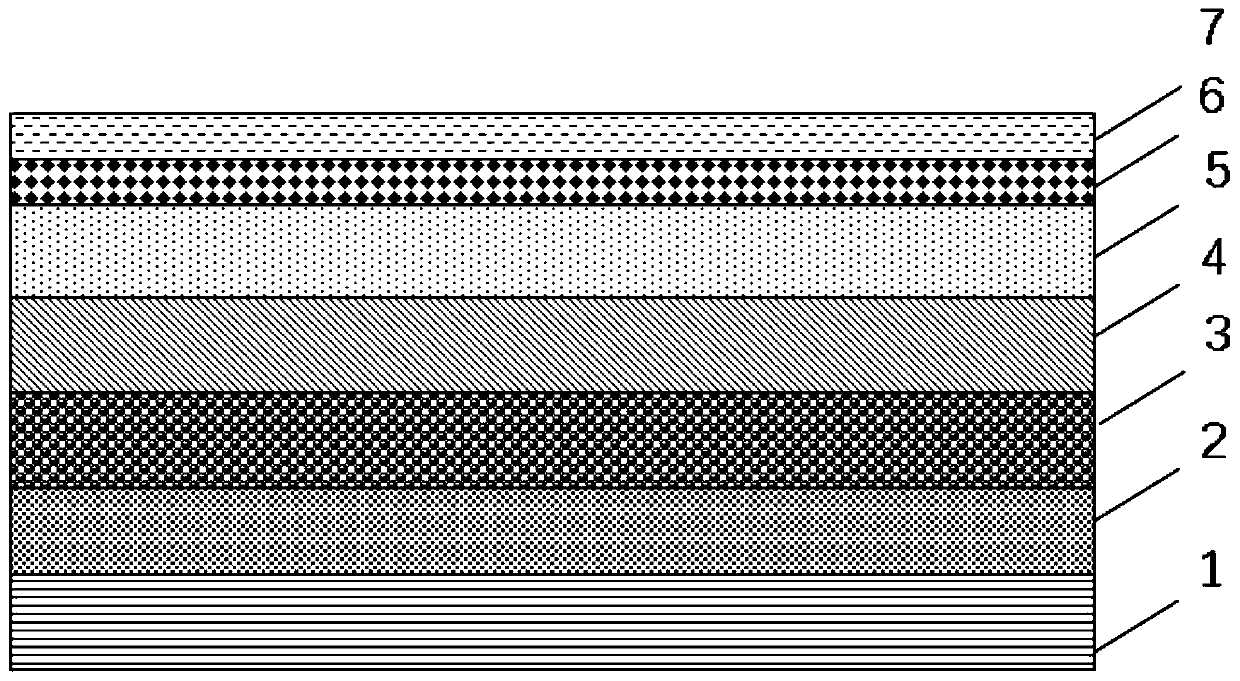

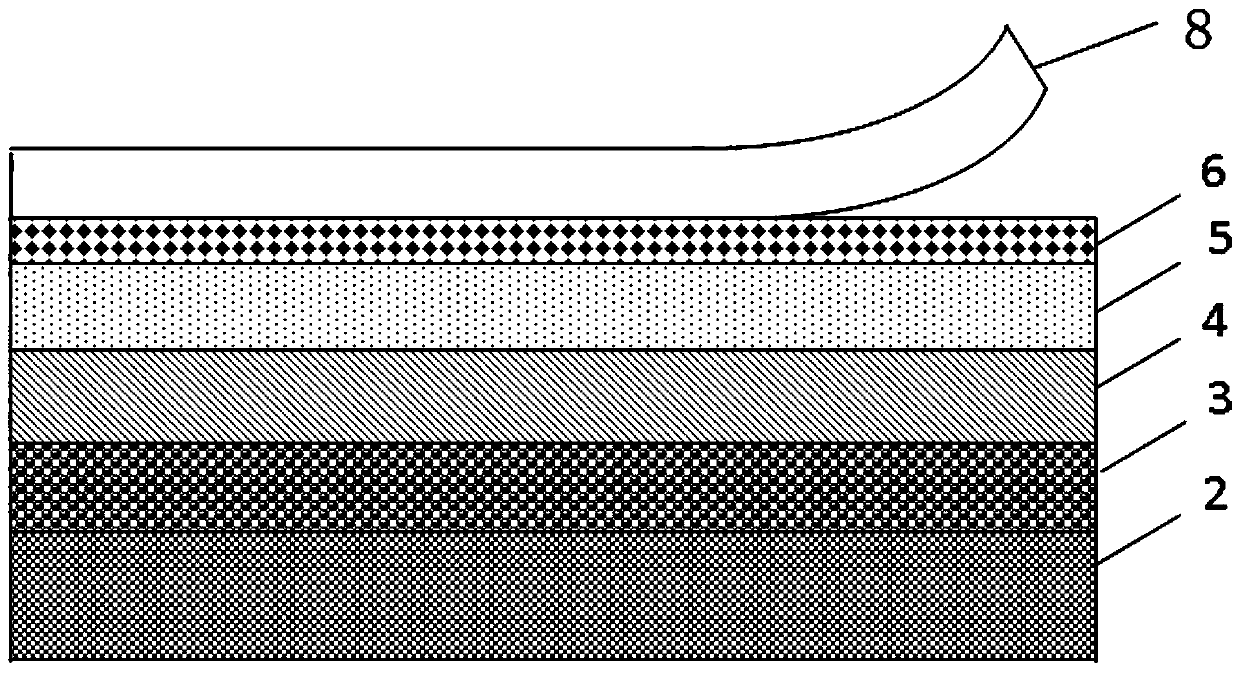

Positioning embossment colorful local transfer paper cup packaging material and preparation method thereof

ActiveCN111321633AAvoid false stickingImprove bindingFlexible coversWrappersInformation layerMetallic aluminum

The invention relates to a positioning embossment colorful local transfer paper cup packaging material and a preparation method thereof. The paper cup packaging material comprises a PLA laminating layer, a base paper layer, an adhesive layer, a metal aluminum layer, a holographic laser information layer, a transfer coating layer and a colorful gloss oil layer which are sequentially compounded frombottom to top. Compared with the prior art, false adhesion between the lamination layer and the gloss oil layer of the paper cup can be avoided; meanwhile, the paper cup packaging material has laserpatterns such as multi-angle diffraction, single-beam embossment, 3D true color holography, a stereoscopic color lens and a white light double-curvature lens, has anti-counterfeiting and environment-friendly effects, is an environment-friendly green packaging material, can present free gradient colors under different light rays, and meets the requirements of different designs and different colorsof the cup body of the paper cup.

Owner:SHANGHAI ZIJIANG METALLIZATION ENVIRONMENTAL PROTECTION MATERIAL +1

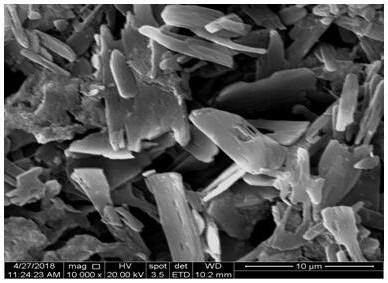

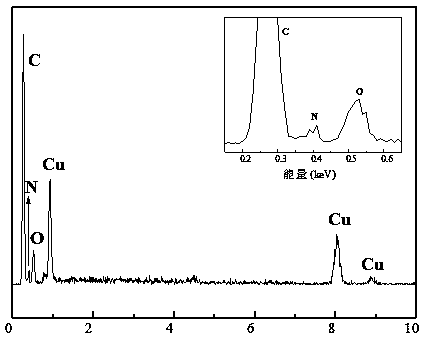

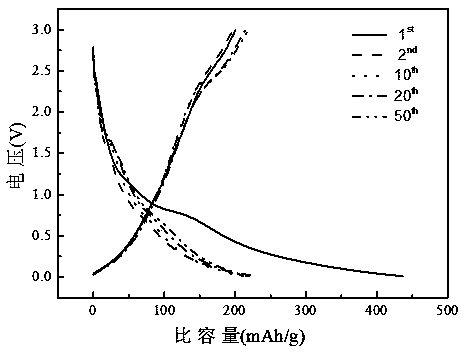

Method for recovering copper ions in acidic copper printed circuit board waste etching liquor and application

ActiveCN109160884AIncrease economic value addedImprove electrochemical performanceOrganic compound preparationCell electrodesRecovery methodEcological environment

The invention discloses a method for recovering copper ions in acidic copper printed circuit board waste etching liquor and application. Copper ions in the acidic copper printed circuit board waste etching liquor are recovered in a form of copper phenylalanine with high added economic value by a liquid deposition method, the recovered copper phenylalanine serving as a negative pole active materialis applied to a lithium ion battery, and the charge and discharge performance and cycling stability of the product are tested by a constant current charging / discharging method. According to the method, the copper ions in acidic copper printed circuit board waste etching liquor can be effectively recovered, waste materials are changed into things of value, the environmental pollution is reduced, green production of the battery industry and sustainable development of ecological environment can be facilitated, and the preparation process is simple, excellent in repeatability and favorable for batch production.

Owner:KUNMING UNIV OF SCI & TECH

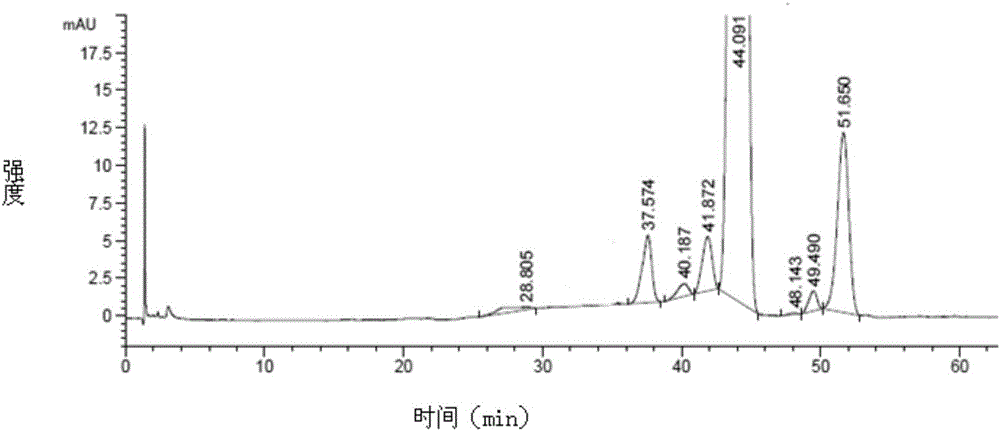

Composite type activated carbon and application thereof in purifying tacrolimus

InactiveCN105819444ASimple processShort timeOrganic chemistryCarbon compoundsSolventActivated carbon

The invention relates to the technical field of drug preparation and discloses composite type activated carbon and the application thereof in purifying tacrolimus. Through fermentation broth filtration, drying, digestion, extraction and washing, composite type activated carbon decoloration and decontamination, and crystal purification, the problems of existing tacrolimus purifying methods that purification yield is low, time consumption is high, elution solvent consumption is high, pollution is serious, and industrialized production can not be achieved easily are solved. By the adoption of the composite type activated carbon and the application thereof in purifying tacrolimus, large-scale production can be achieved easily, solvent consumption is low, production cycle is short, an obtained tacrolimus crude product is high in purity and is white or off-white color powder, weight fraction is 85% or more, and HPLC normalized concentration is 90% or more.

Owner:HANGZHOU ZHONGMEI HUADONG PHARMA

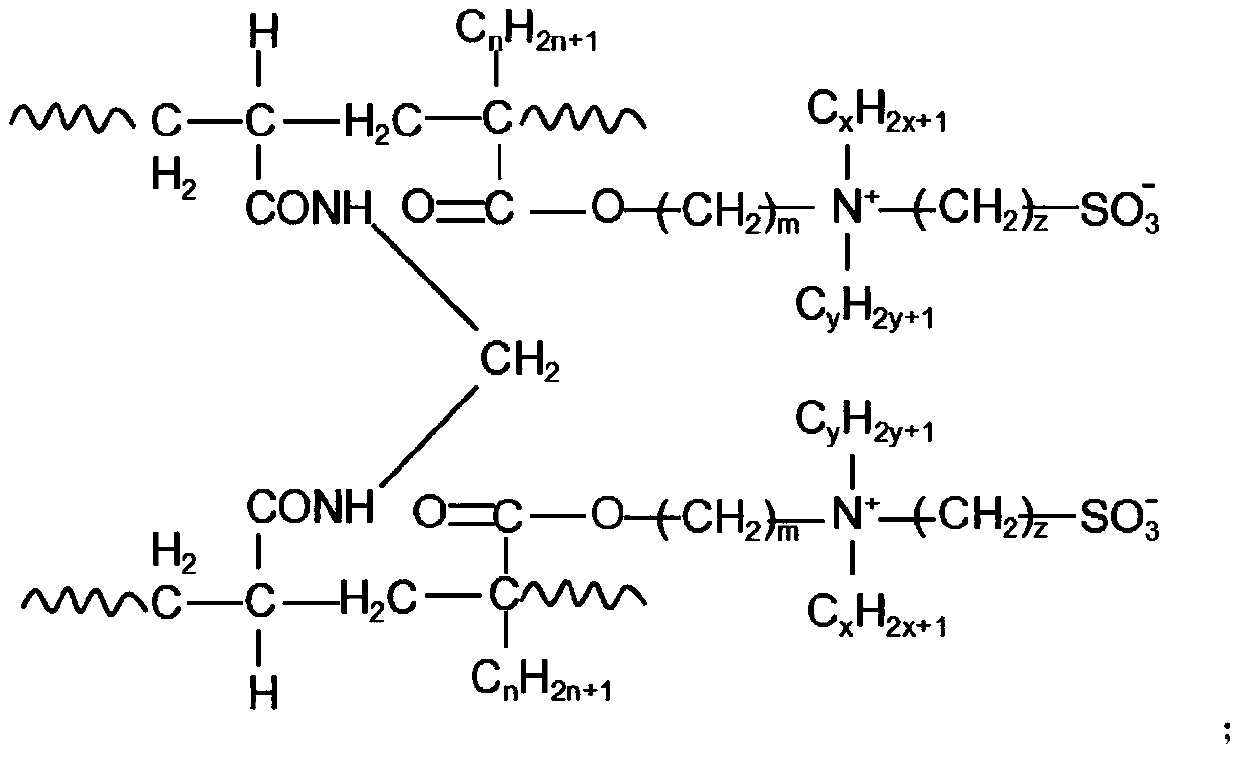

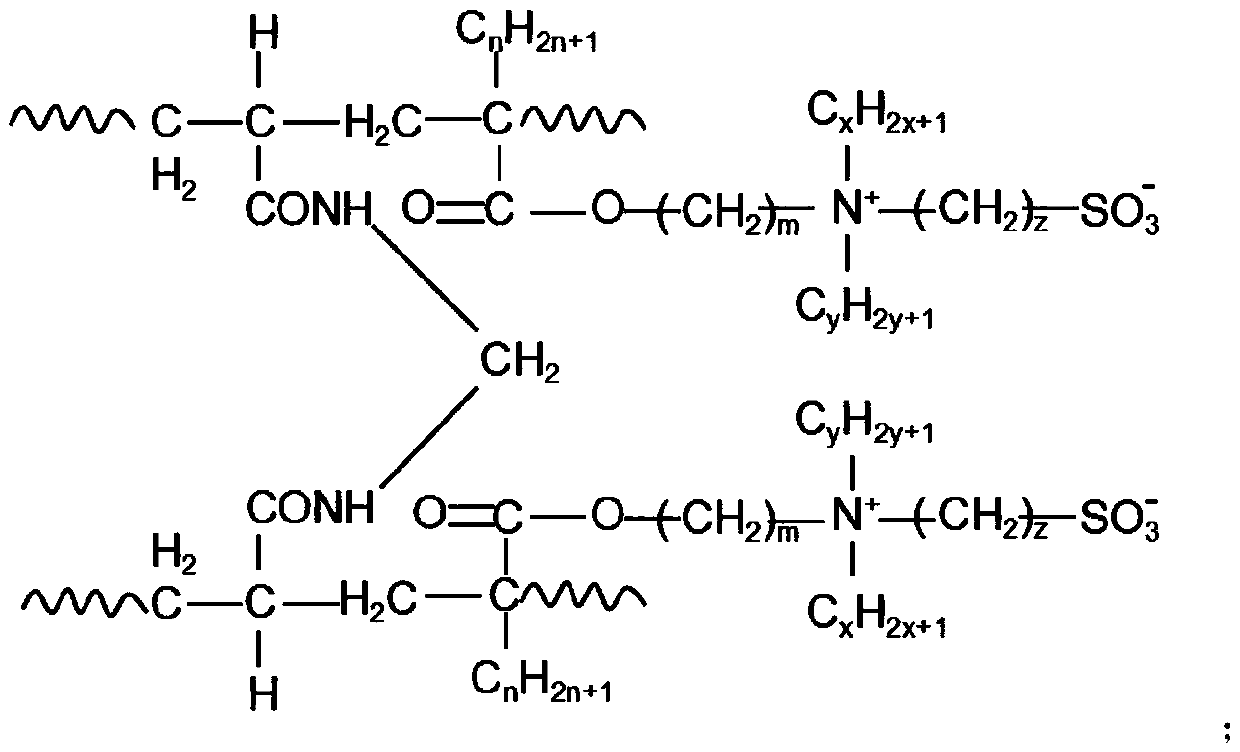

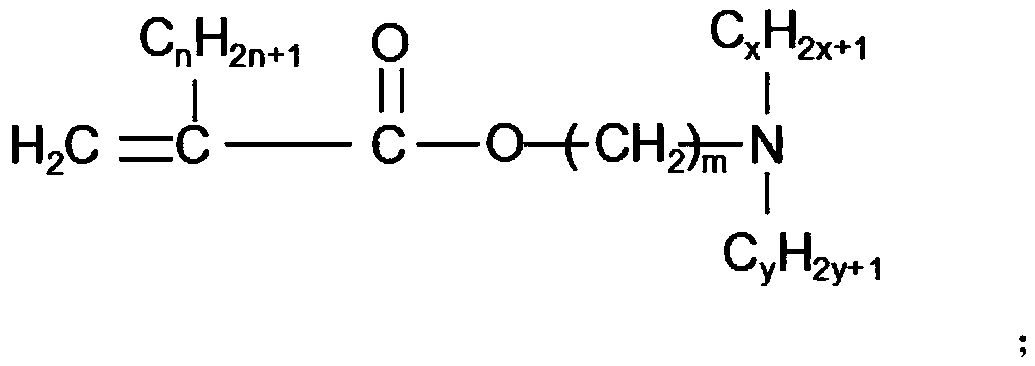

Anti-settling aid, and preparation method and application thereof

ActiveCN110818835APromote green productionReduce manufacturing costSulfonic acids salts preparationPolymer scienceFunctional monomer

The invention discloses an anti-settling aid, and a preparation method and application thereof. The preparation method comprises the following steps: generating a functional monomer B from sultone, afunctional monomer A and a small amount of polymerization inhibitor at a certain temperature; adding the obtained functional monomer B and neutral monomer acrylamide into a certain amount of sodium chloride solution, and carrying out a copolymerization reaction under the action of an initiator to obtain a zwitterionic copolymer; and carrying out co-heating on the zwitterionic copolymer and an aqueous cross-linking agent solution in a hydrochloric acid solution for a cross-linking reaction so as to obtain an amphoteric micro-cross-linked polymer. Based on reverse polyelectrolyte effect and micro-crosslinking effect, the amphoteric micro-crosslinked anti-settling aid applicable to wet-ground concrete waste slurry high-salt system is developed; and compared with the prior art, the amphotericmicro-crosslinked anti-settling aid has remarkable beneficial effects.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD +1

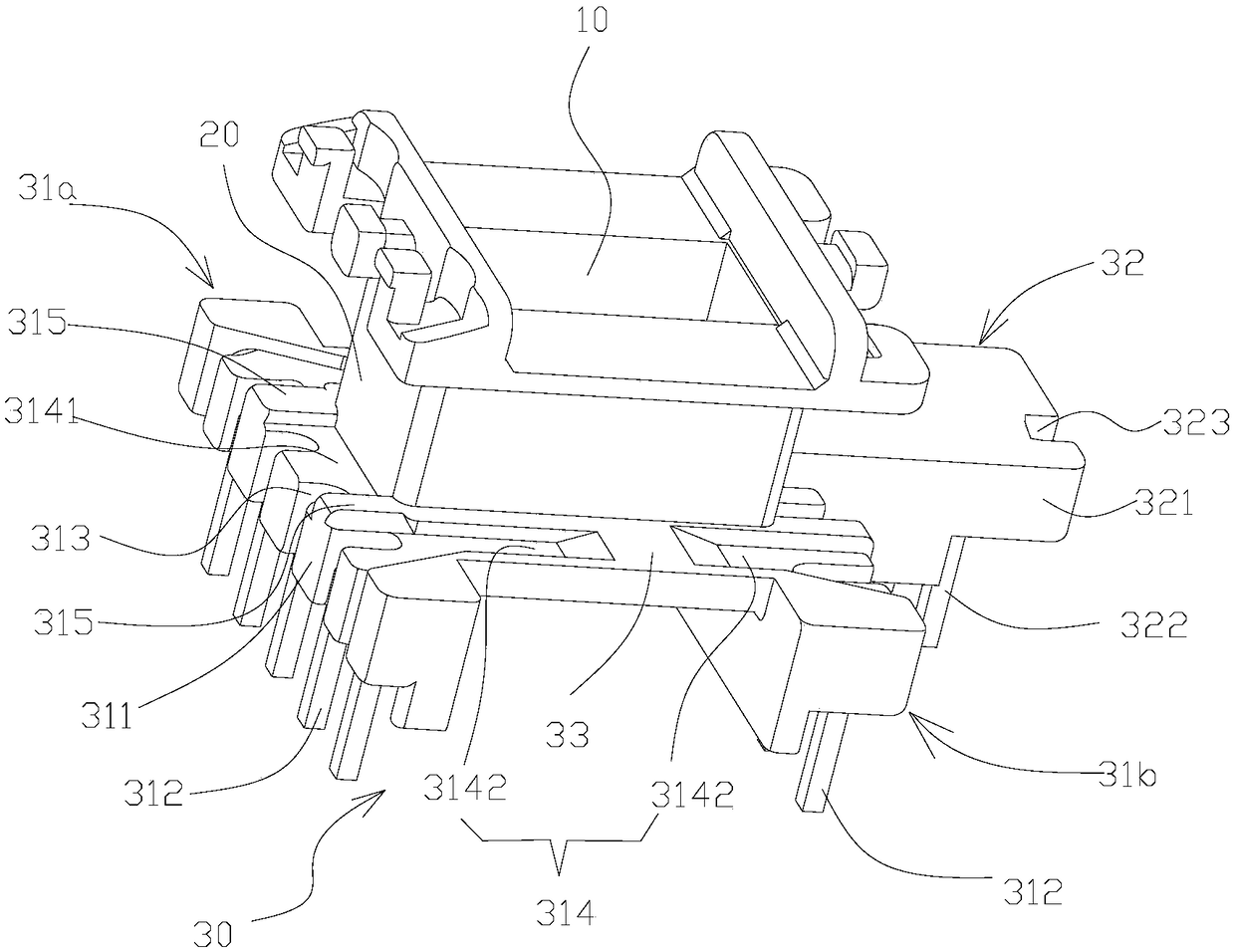

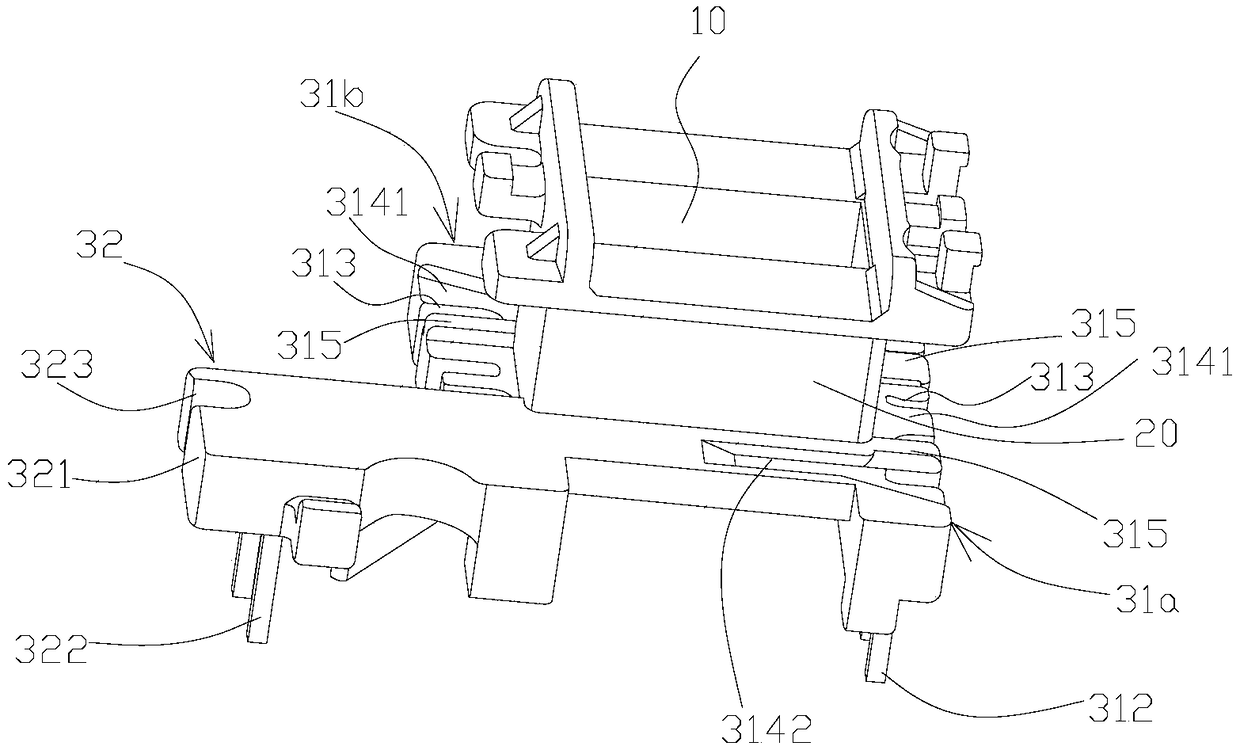

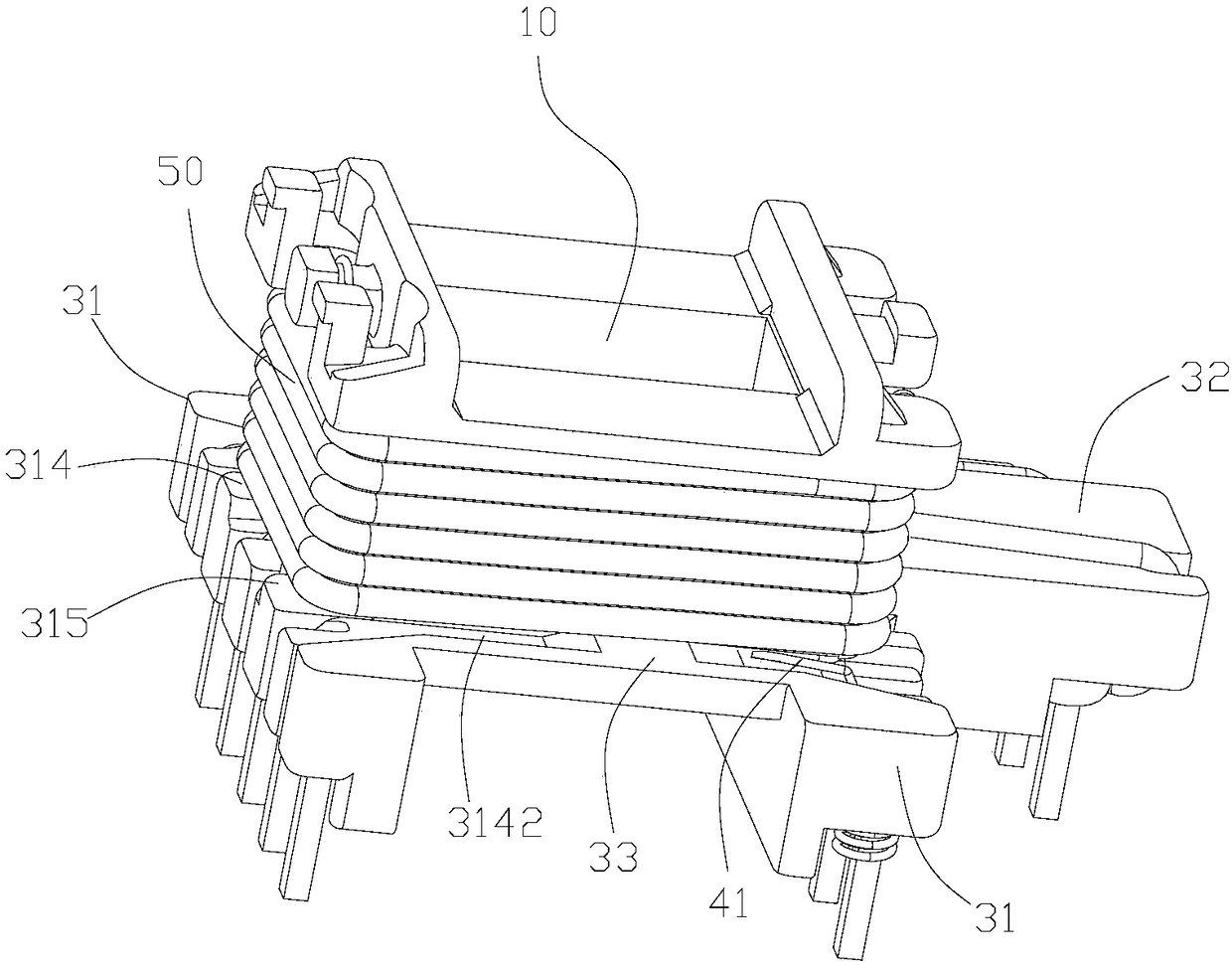

Transformer framework preventing winding lead wire from crossing

InactiveCN109285676AAvoid damageAvoid direct cross contactTransformers/inductances coils/windings/connectionsTransformerEngineering

The invention provides a transformer framework preventing a winding lead wire from crossing. The transformer framework comprises a magnetic core groove and a winding framework body arranged at the endof the magnetic core groove; the outer wall of the magnetic core groove and the winding framework body form a winding groove for winding a primary coil and a secondary coil; the winding framework body comprises a primary framework body and a secondary framework body; the primary framework body extends outwards to be provided with a plurality of primary wire hanging columns distributed at intervals, each primary wire hanging column is provided with a primary pin perpendicular to the primary wire hanging column, and a primary wire crossing groove is formed in a gap of every two primary wire hanging columns; the primary framework body is provided with primary wire guiding grooves flush with or lower than the primary framework body and communicated with the primary wire crossing grooves, so that a lead wire of the primary coil winding the winding groove passes through the primary wire guiding grooves in a horizontal or obliquely-downward wire outlet mode, penetrates through the primary wire crossing grooves, bypasses the primary wire hanging columns and finally winds the primary pins, and a height difference is formed between the lead wire of the primary coil and the secondary coil winding the periphery of the lead wire. The transformer framework can achieve the full-automated production of a transformer.

Owner:DONGGUAN AOHAI TECH CO LTD

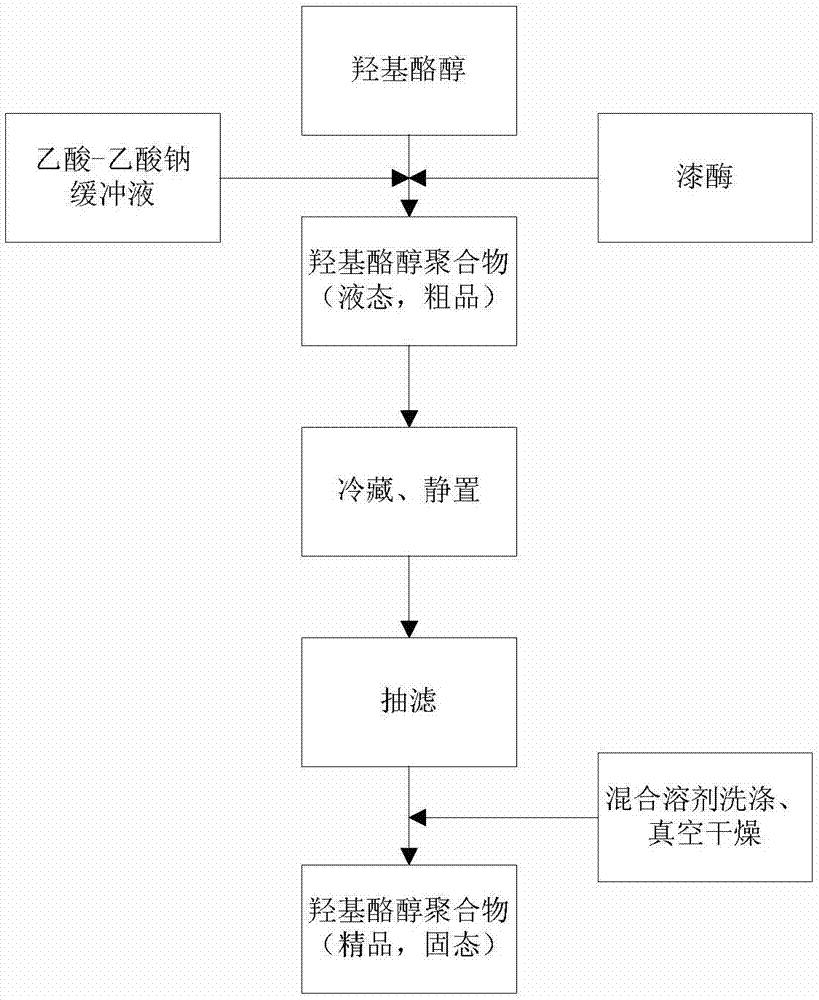

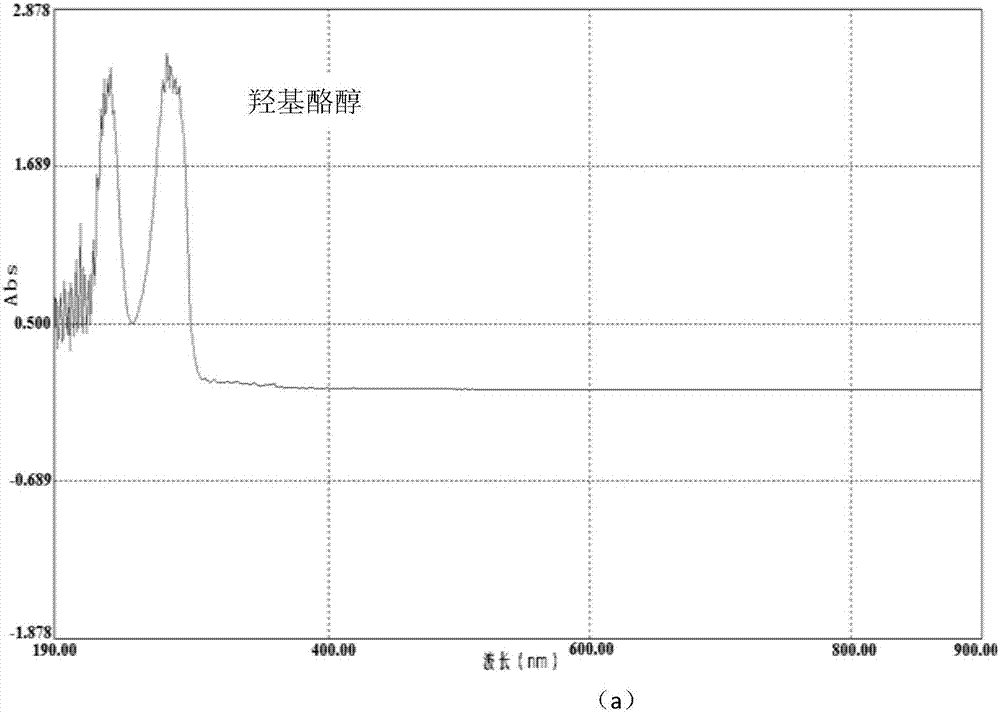

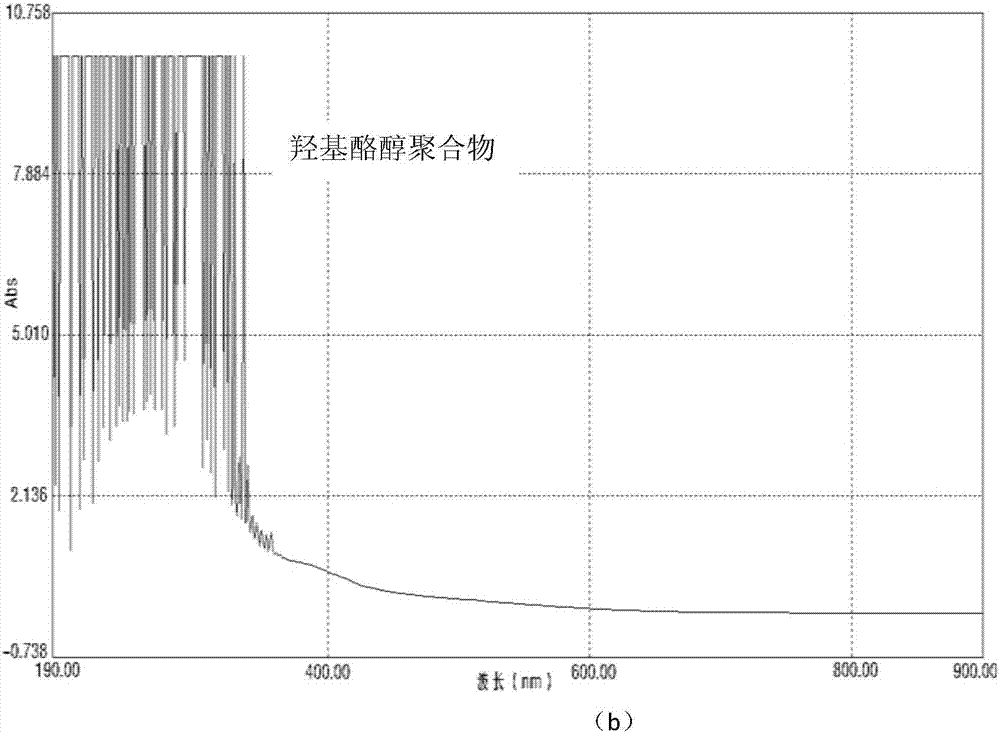

Hydroxytyrosol polymer having high antioxidation and thermal stability and preparation method thereof

The invention discloses a hydroxytyrosol polymer having high antioxidation and thermal stability and a preparation method thereof. The method comprises the following steps: firstly, enzymatic polymerization: dissolving hydroxytyrosol in acetic acid-sodium acetate buffer, and fully mixing with a laccase solution to generate water bath reaction; secondly, precipitation and centrifugation: placing liquid obtained from enzymatic polymerization immediately in a high temperature condition to enable laccase to inactivate, cooling to enable the polymer to precipitate, and centrifuging again to obtain crude hydroxytyrosol polymer; thirdly, washing and vacuum drying: washing collected crude hydroxytyrosol polymer with a mixed organic solvent for a plurality of times, to remove unreacted hydroxytyrosol and laccase, and performing vacuum drying to remove the solvent to obtain the final hydroxyl group butyrol polymer. The stability of a product is good, the oxidation resistance is strong, and the production process is green.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

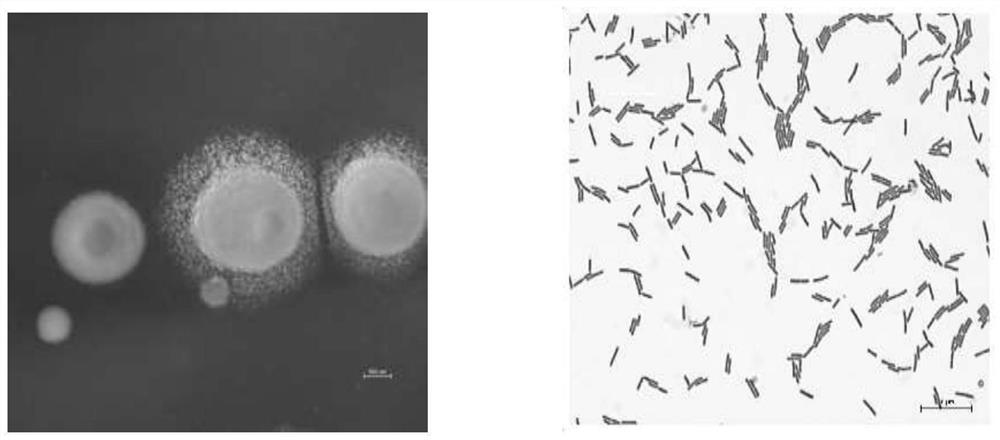

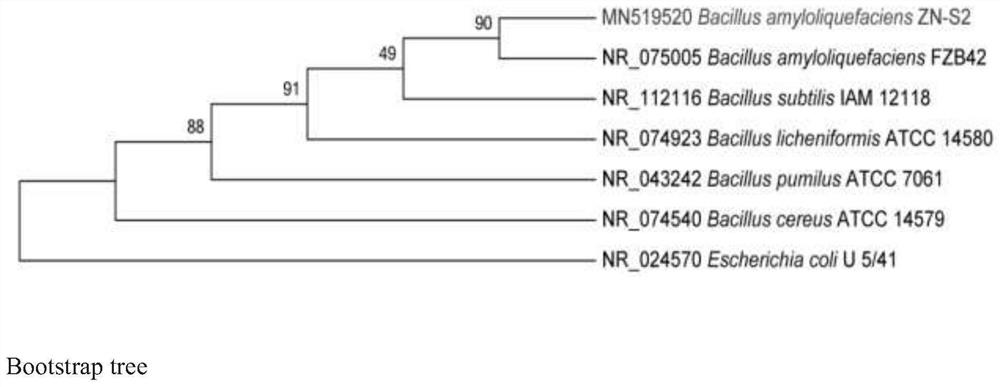

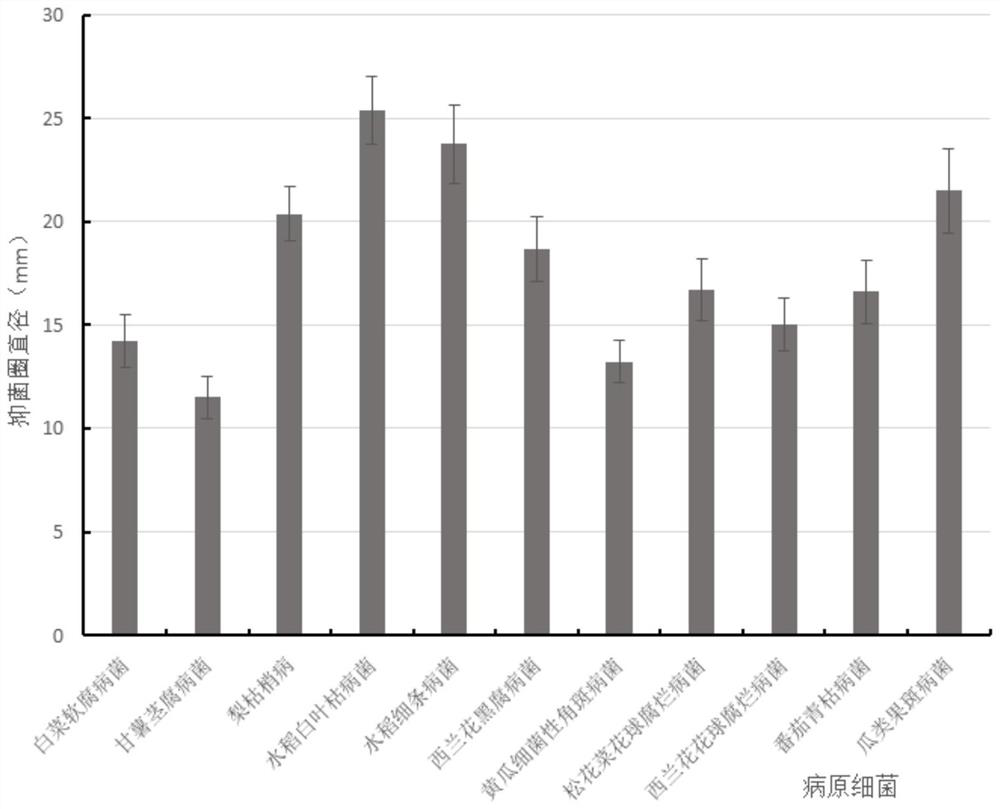

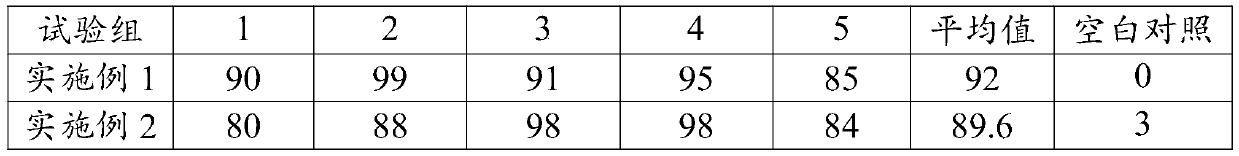

Biocontrol plant endophytic bacterium ZN-S2 and application thereof

PendingCN112694998AEnhance colonization abilityGood compatibilityBiocideBacteriaBiotechnologyBacillus amyloliquefaciens

The invention discloses bacillus amyloliquefaciens ZN-S2, and the preservation number of the bacillus amyloliquefaciens ZN-S2 is CGMCCNO:18962. The invention further provides application of the bacillus amyloliquefaciens ZN-S2 at the same time, wherein the bacillus amyloliquefaciens ZN-S2 is used for inhibiting the growth of plant pathogenic bacteria, so that the plant bacterial diseases are prevented and controlled.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Attractant for tea-seed weevil

ActiveCN111096338AImprove booby effectBooby efficientBiocidePest attractantsCamellia oleiferaTert butyl

The invention discloses an attractant for tea-seed weevil. The attractant is prepared from the following components: schizonepeta lactone, schizonepeta alcohol, cis-3-hexene-1-ol, honeysuckle flower powder, 2, 6-di-tert-butyl-p-cresol, 2-hydroxy-4-methoxybenzophenone, n-pentadecane and ethanol. According to the attractant disclosed by the invention, a botanical attractant and a sex attractant arereasonably matched to obtain a cooperative technical effect and have the significant trapping and killing; and moreover, the attractant has the advantages of being simple in use method, efficient in trapping and killing, environmentally friendly, long in use period and the like, the use amount of pesticide can be greatly reduced when the tea-seed weevil is prevented and controlled, the damage rateof oil-tea camellia fruits is reduced, green production of oil-tea camellia is facilitated, and the quality of the oil-tea camellia is improved.

Owner:HUNAN ACAD OF FORESTRY

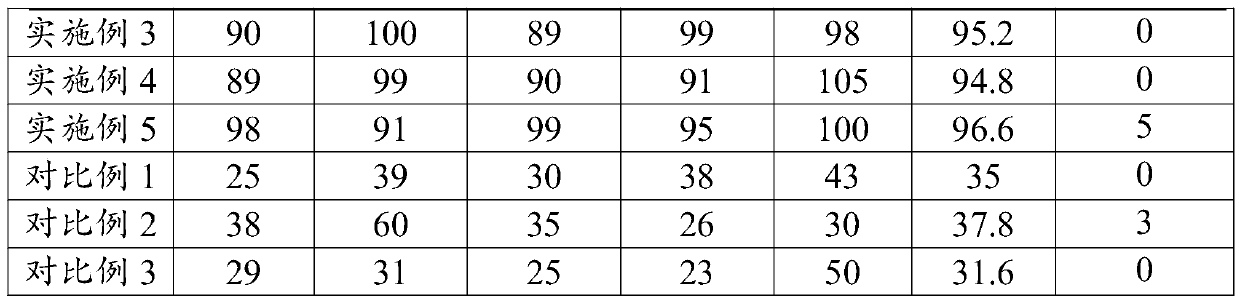

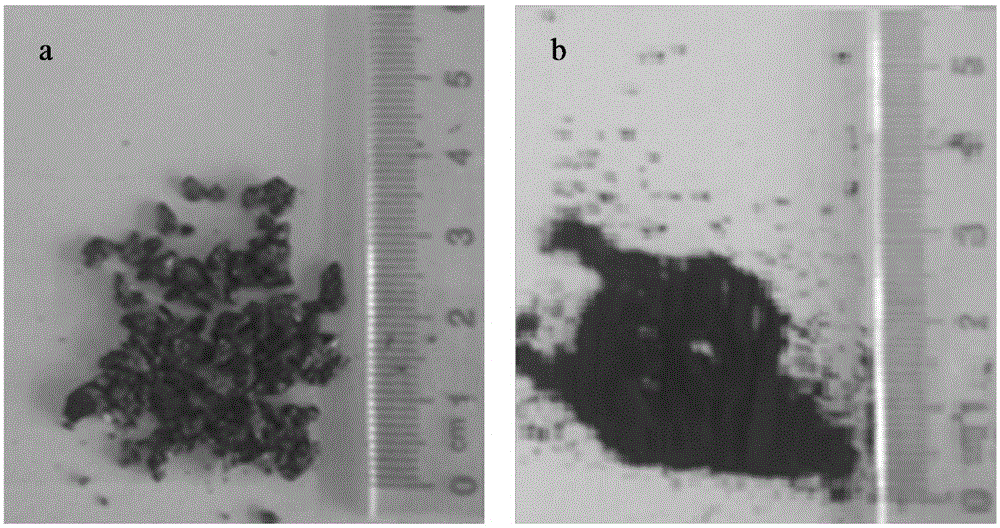

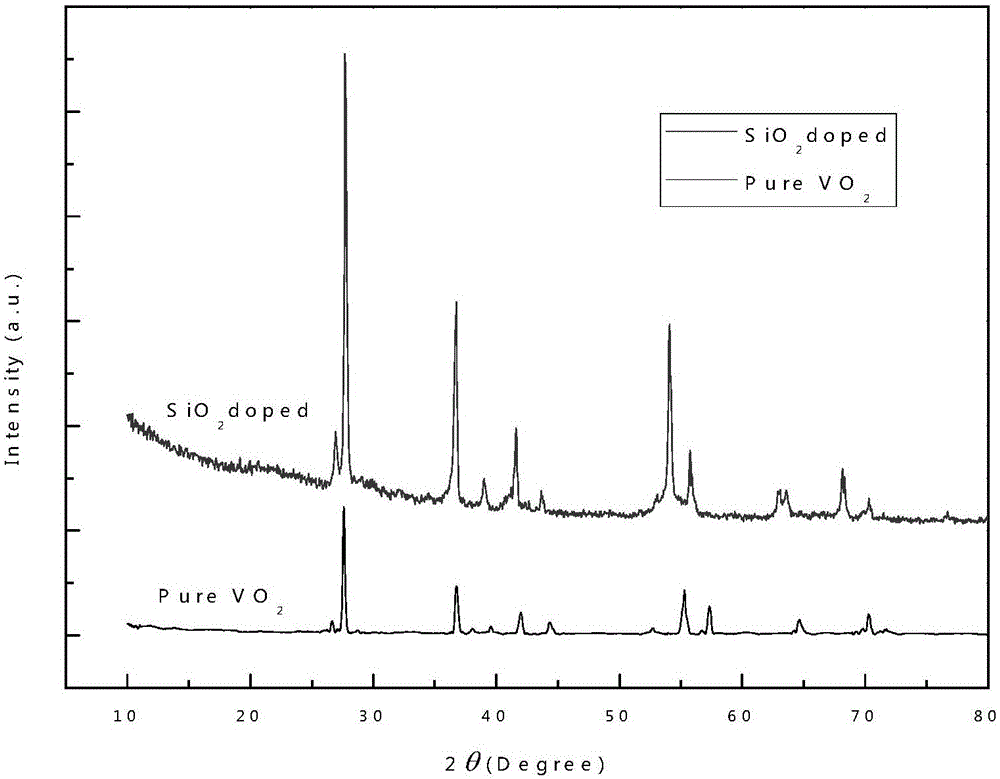

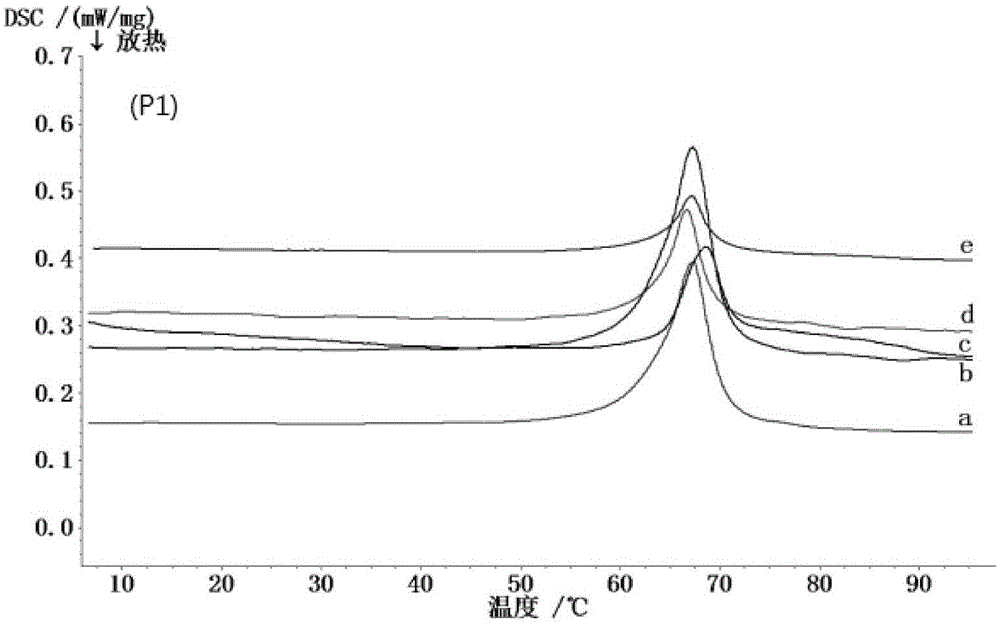

Preparation method of ultrafine vanadium dioxide powder

ActiveCN105016386ALow costNo pollution in the processMaterial nanotechnologyVanadium oxidesVanadium dioxideFiltration

The invention relates to a preparation method of ultrafine vanadium dioxide powder. The preparation method comprises steps as follows: Step 1, dissolving vanadyl sulfate trihydrate in distilled water, adding an alkaline solution, adjusting the PH of the solution to range from 6 to 7 to obtain a suspension, and performing suction filtration, cleaning and drying to obtain product precursor powder; Step 2, crushing silicon dioxide aerogel and screening out silicon dioxide aerogel powder by a screen; Step 3, mixing the product precursor powder obtained in Step 1 with the silicon dioxide aerogel powder obtained in Step 2 in the weight ratio being (1-10):1 to obtain mixed powder, Step 4, performing heat treatment on the mixed powder obtained in Step 3 under the protection of inertial gas and then cooling the mixed powder, wherein the heat treatment temperature is in a range of 600-1000 DEG C and the heat treatment time is in a range of 3-8 h; Step 5, screening the mixed powder cooled in Step 4 by a screen of 1000-3000 meshes to remove large-particle silicon dioxide aerogel powder.

Owner:GUANGZHOU UNIVERSITY

Separation and purification method of acetylacetone salt and solvent used by separation and purification method

InactiveCN107266301ATo achieve the purpose of separation and purificationGood separation and purification effectCarbonyl compound separation/purificationPurification methodsAcetylacetone

The invention relates to a separation and purification method of acetylacetone salt and a solvent used by the separation and purification method. The solvent comprises 30-70 parts of main solvent, 10-20 parts of auxiliary solvent, 0.1-1 part of solubilizer, 0.1-1 part of dispersing agent and 0.1-1 part of stabilizer. The separation and purification method includes the steps of firstly, sequentially adding the main solvent and the auxiliary solvent into a reaction container, stirring, sequentially adding the dispersing agent, a cosolvent and the stabilizer while stirring after the main solvent and the auxiliary solvent are evenly mixed, and evenly mixing to obtain a mixed solvent system; secondly, adding crude acetylacetone salt into the mixed solvent system obtained in the first step to dissolve the crude acetylacetone salt, and filtering the solution to obtain filtrate; thirdly, distilling of the filtrate to obtain solid, namely pure acetylacetone salt. The purity of the acetylacetone salt separated and purified by the method can reach above 99%.

Owner:ANHUI JIAXIAN FUNCTIONAL AUXILIARY +1

Pollution-free prevention and control method of camellia oleifera plant diseases and insect pests

InactiveCN111386949APromote green productionImprove disease resistanceBiocideDisinfectantsCamellia oleiferaPest control

The present invention belongs to the technical field of plant disease and insect pest prevention and control and specifically relates to a pollution-free prevention and control method of camellia oleifera plant diseases and insect pests. The method comprises the following steps: (1) forest land fertilizing; (2) forest land interplanting; (3) forest management; and (4) pesticide prevention and control. The method combines the forest land fertilizing, forest land interplanting, forest management and pesticide prevention and control, and uses prevention as the main and prevention and control as the supplement, based on a forest culture and management technology, comprehensive prevention and control measures combining biological and pesticide prevention and control are used to conduct prevention and control of common plant diseases and insect pests of camellia oleifera, and the method can effectively reduce incidence of various plant diseases and insect pests of the camellia oleifera without causing other pollution at the same time, is beneficial to green production of the camellia oleifera and improves planting efficiency.

Owner:株洲市地杰现代农业有限责任公司

Method for preparing 13X molecular sieve through using high-alumina fly ash, and 13X molecular sieve

InactiveCN103449467BLow costOvercoming the disadvantage of relatively low silica contentSolid waste disposalFaujasite aluminosilicate zeoliteMolecular sieveFly ash

The invention provides a method for preparing a 13X molecular sieve through using high-alumina fly ash, and the 13X molecular sieve. The preparation method comprises the following steps: mixing the high-alumina fly ash with an alkali solution for a pre-desiliconization reaction, and filtering to obtain a desiliconized solution; mixing the desiliconized solution with white carbon black to obtain a modified desiliconized solution; mixing the modified desiliconized solution with an aluminum sauce to obtain a silicon and aluminum sol; and crystallizing the silicon and aluminum sol, filtering, washing, and drying to prepare the 13X molecular sieve. The invention also provides the 13X molecular sieve prepared through the preparation method.

Owner:DATANG INT CHEM TECH RESINST

High-strength antifriction aluminum alloy and preparation method thereof

The invention relates to high-strength antifriction aluminum alloy comprising the components of, by weight, 1.0%-9.0% of bismuth, 2.0%-8.0% of copper, 0.3%-1.7% of manganese, 0.2%-1.7% of silicon, 0.3%-2.2% of magnesium, 0-0.7% of impurities, and the balance aluminum. According to the high-strength antifriction aluminum alloy, bismuth, copper, manganese, silicon, magnesium and other elements are added, strength and antifriction performance of an aluminum substrate are improved through alloying, and the requirement of a high-pressure gear pump is fully met. The grain size grade index of the microstructure of the prepared aluminum alloy reaches 7-8 grade, the tensile strength can reach 450-470 Mpa, and the friction coefficient is smaller than 0.02. The mechanical property of the aluminum alloy material is improved, and meanwhile, good processability, low surface roughness and other advantages are achieved. Meanwhile, the components of the aluminum alloy do not contain heavy metal, harm to human bodies and the environment due to the fact that heavy metal, such as lead, is widely used in existing aluminum alloy materials is avoided, and important positive significance is achieved for facilitating green and environment-friendly production.

Owner:安徽熠辉新材料有限公司

A kind of biocontrol actinomycetes strain and application thereof for preventing and treating tobacco bacterial wilt

The invention discloses an actinomycete strain for preventing and treating tobacco bacterial wilt and an application method thereof, belonging to the technical field of microorganisms. The strain is Streptomyces sp. K4, which has been deposited in the General Microbiology Center of China Committee for the Collection of Microorganisms, with the date of preservation being March 24, 2014, and the preservation number is CGMCC NO.8949. The bacterial strain inhibits the growth of tobacco bacterial wilt by producing active substances, and shows better control effect on tobacco bacterial wilt. The biocontrol actinomycete strain is used to prepare a biocontrol agent, which can be used with root-fixing water when transplanting tobacco seedlings; or can be used after root irrigation 4-5 days after transplanting. The bacterial agent can also be mixed with organic fertilizer to make bacterial fertilizer. The strain K4 is obtained from the rhizosphere soil of the tobacco field, and is compatible with the soil ecology, so it has a good application prospect in the biological control of tobacco bacterial wilt.

Owner:INST OF PLANT PROTECTION FAAS

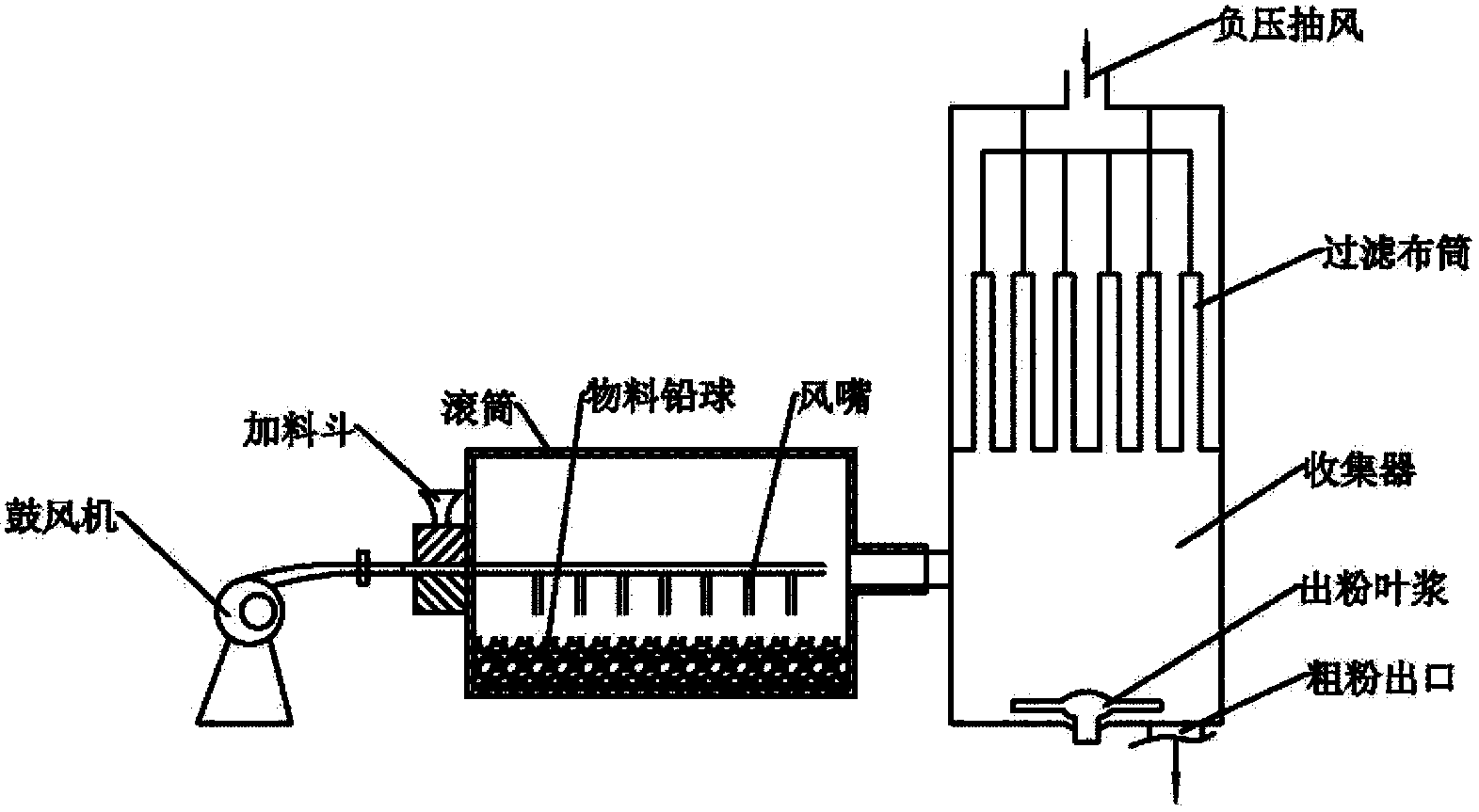

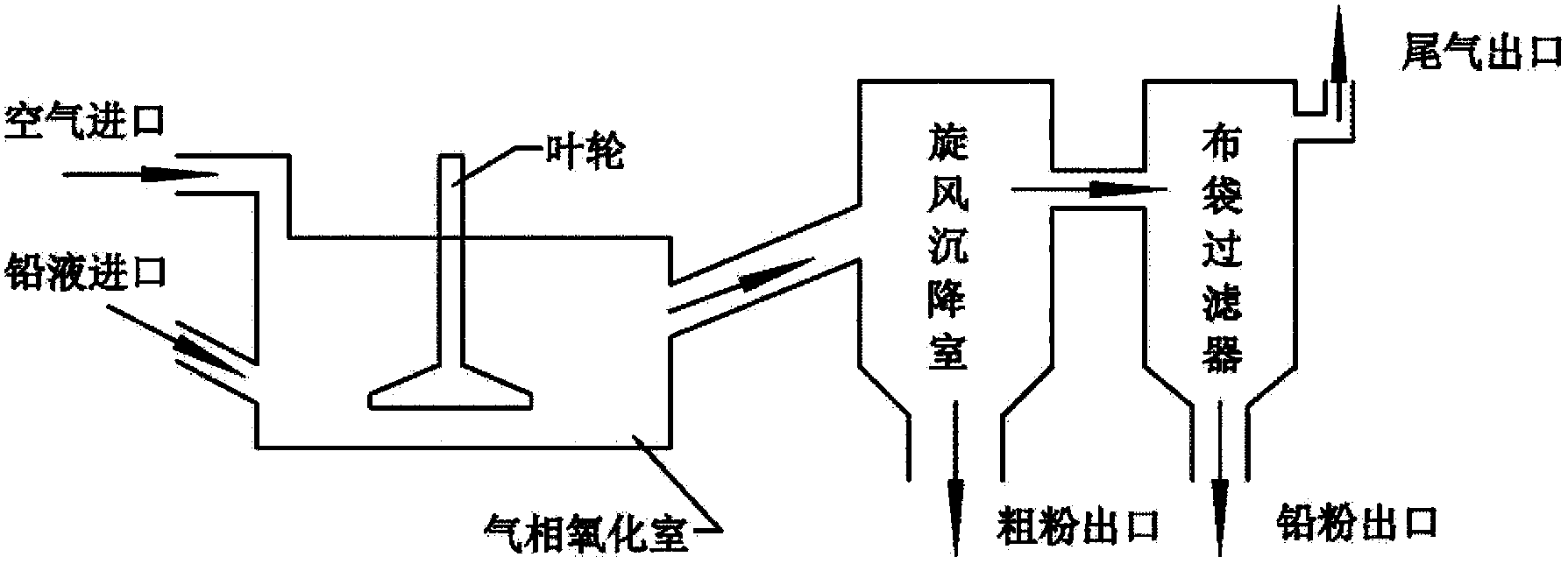

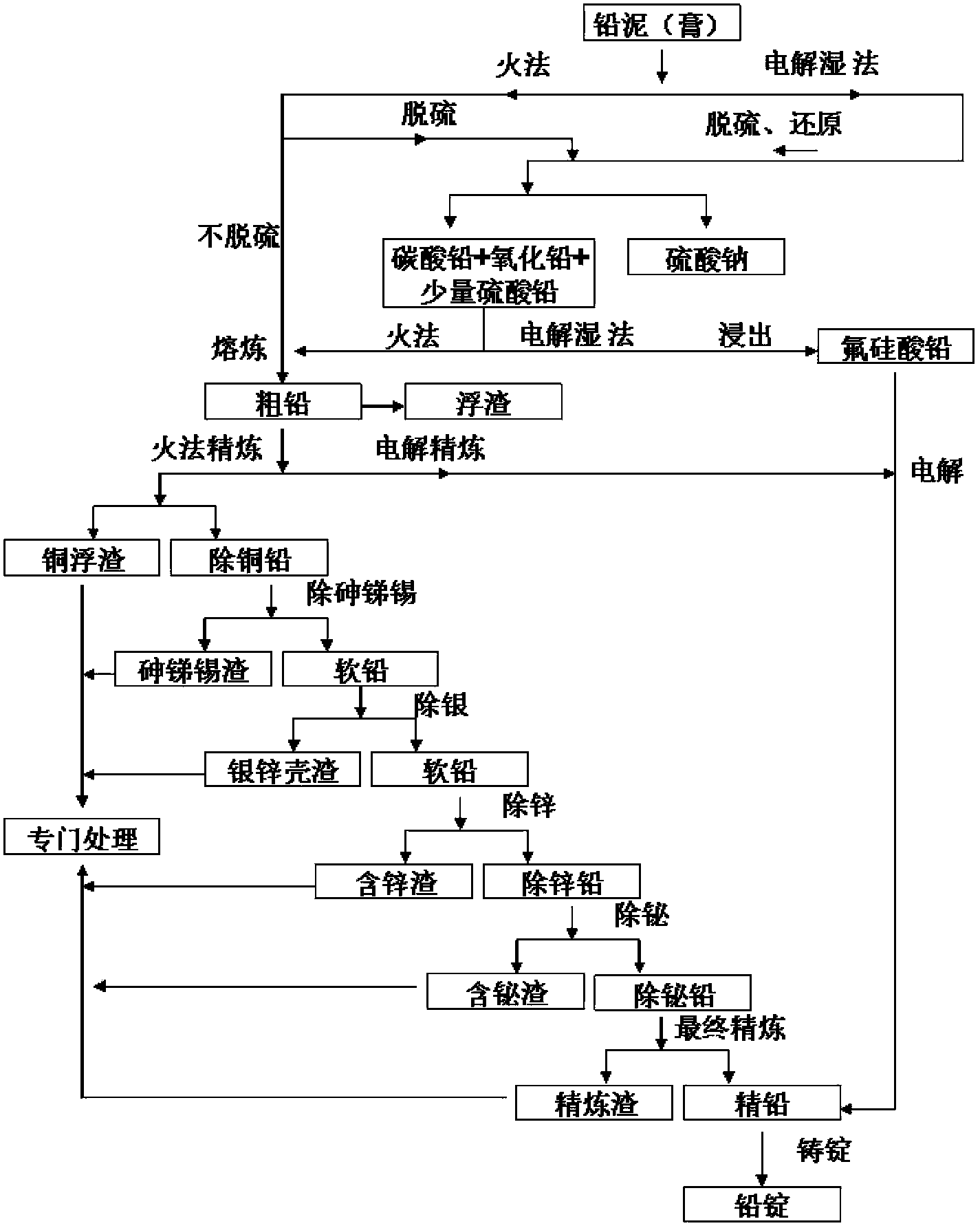

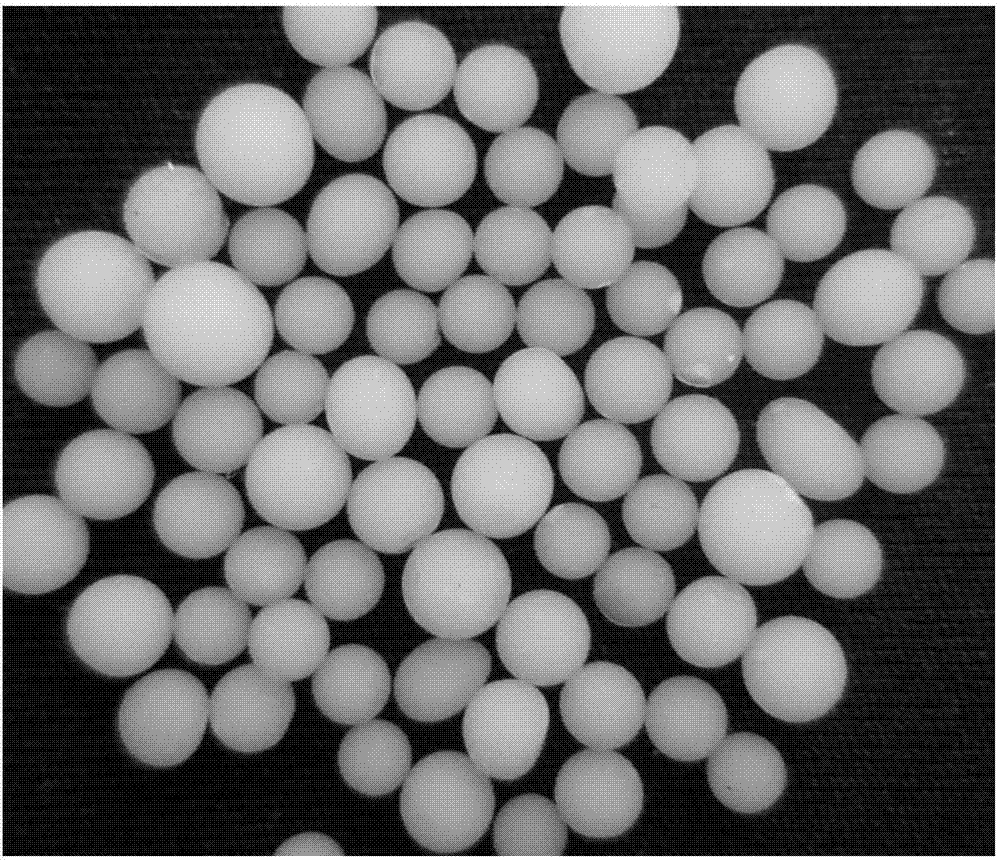

Method and equipment for wet recovery of waste lead paste and wet production of high-performance lead-acid battery electrode active material

ActiveCN103509949BIncrease profitLarge particle sizeWaste accumulators reclaimingProcess efficiency improvementElectrical batteryHazardous substance

The invention discloses methods and equipment for recovering waste diachylon by a wet method and manufacturing an electrode active substance material of a high performance lead acid battery by the wet method. The equipment comprises device required for a technology process by a chemical method, a chemical machinery method or an electrochemical machinery method. The active substance material provided by the invention can substantially raises an utilization rate of the active substance of the lead acid battery, specific energy of the battery and charging capability of the battery, simultaneously avoids generation and discharge of harmful substances such as lead gas, lead smoke, lead dust and SO2, raises a lead utilization rate in a production process, is beneficial for treating and recycling lead compounds and lead-containing liquid generated in a lead gas recovering process in a plate casting or welding technology, and reduces cost.

Owner:杨春晓

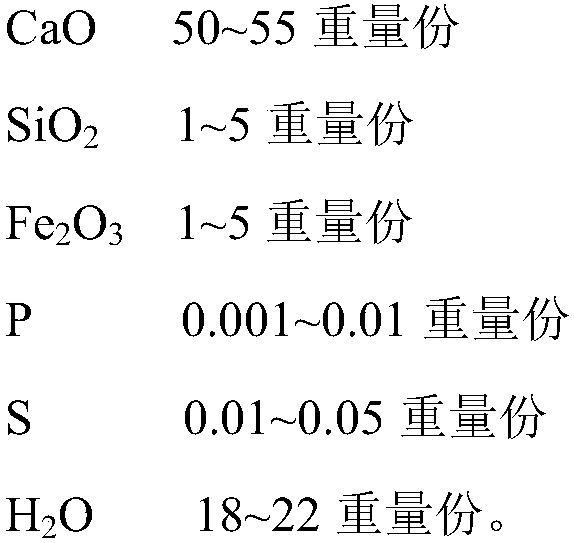

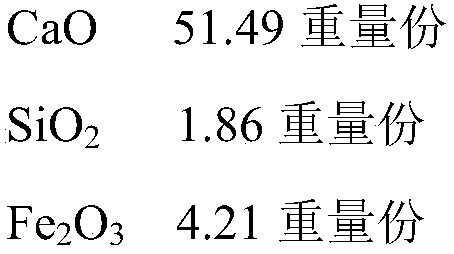

Method for improving compression forming rate of limestone mud cakes

The invention provides a method for improving a compression forming rate of limestone mud cakes. The method comprises the following steps that the limestone mud cakes are airing dried until the moisture content is not more than 10 wt% and below; a digestion material is formed by stacking and digesting; the digested material is crushed and stirred to form a mixture material; and a binding agent water glass which accounts for 5 wt%-10 wt% of the digestion material is added during the crushing and stirring process; and the mixture material enters a ball pressing machine to be pressed and formed.According to the technical scheme, the method is simple and feasible, the ball forming rate of the limestone mud cakes is over 85% and above, each limestone mud cake freely drops from a two meter height to a cement terrace at one time, and no more than 5 blocks are broken after each limestone mud cake being crushed; the compression forming rate of the limestone mud cakes is effectively improved byadopting the method, and a daily amount of a limestone mud cake ball compression production line is 80 tons.

Owner:MCC BAOSTEEL TECH SERVICE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com