Hydroxytyrosol polymer having high antioxidation and thermal stability and preparation method thereof

A technology of hydroxytyrosol and thermal stability, which is applied in the field of preparation of hydroxytyrosol polymers, can solve problems such as poor stability of hydroxytyrosol, corrosion environment of industrial equipment, weak oxidation resistance, etc., and achieve good product quality and green cycle Good economic performance and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

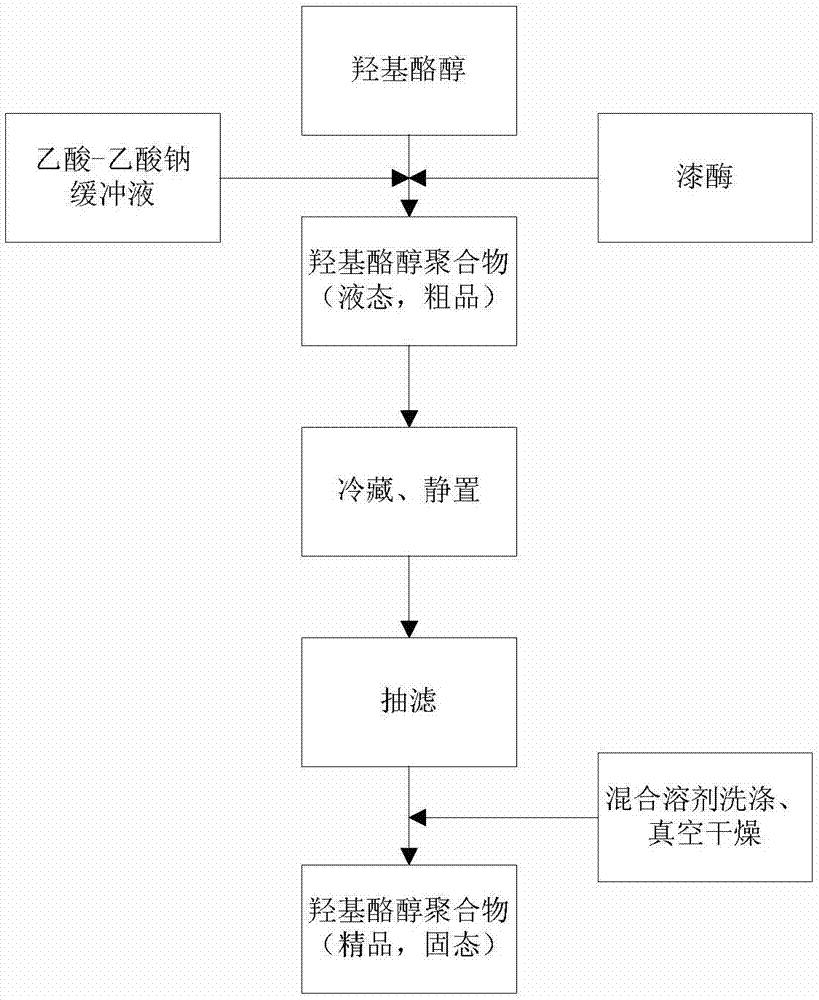

[0034] A method for preparing hydroxytyrosol polymer with high oxidation resistance and thermal stability, the steps are:

[0035] The first step, enzymatic polymerization: Weigh an appropriate amount of hydroxytyrosol, dissolve it in acetic acid-sodium acetate buffer, mix it with an appropriate amount of laccase solution, place it in a flask and put it in a water bath at a certain temperature, and stir it magnetically. hour.

[0036] The second step, precipitation and centrifugation: the liquid after the enzymatic reaction is immediately placed at a high temperature to inactivate the laccase, and placed in the refrigerator at a certain temperature for several hours to precipitate the polymer. Under certain speed and time conditions, the crude hydroxytyrosol polymer is obtained by centrifugation through a centrifuge.

[0037] The third step, washing, vacuum drying: the collected crude hydroxytyrosol polymer is washed several times with a certain proportion of mixed organic solvents ...

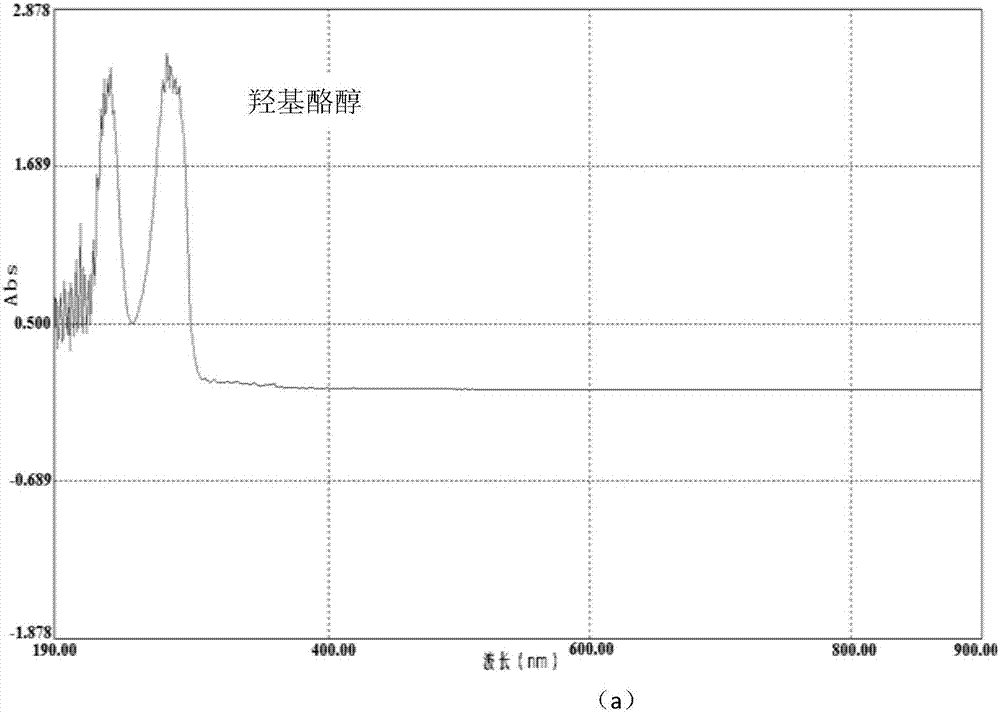

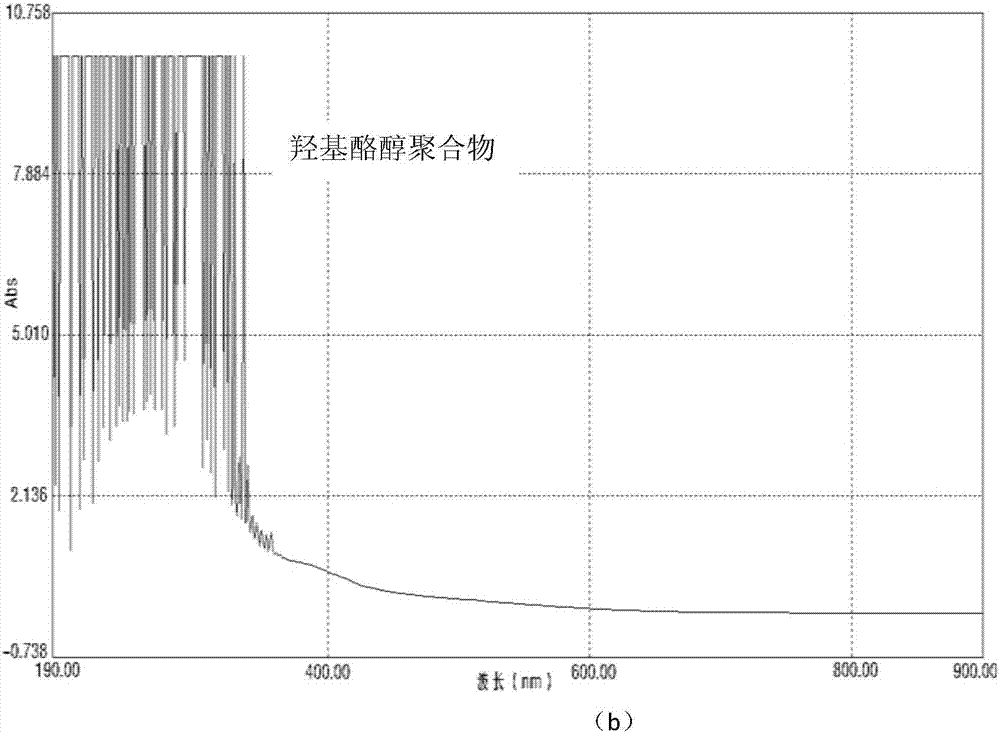

Embodiment 1

[0048] Dissolve 1 mM hydroxytyrosol in 30 mL acetate buffer (0.05M, pH 4.7). In the enzymatic polymerization reaction, laccase solution (1.0 mg / mL, enzyme activity 300 U) was initially added. Place the flasks containing different reagents at 35°C with magnetic stirring for 3h, and then inactivate the laccase at 90°C. During the enzymatic reaction, the color of the reaction medium gradually darkens and can be used to indicate the general progress of the polymerization reaction. After the polymerization reaction is completed, the reaction vessel is placed in a refrigerator at 4°C for 20 hours to precipitate the polymerization product. Then the precipitate was obtained by centrifugation at 3500 r / min for 6 min, and washed several times with a mixed solvent of acetone and deionized water (1:1, v / v) to remove unreacted hydroxytyrosol and laccase. The resulting polymer is placed in a temperature range of 60°C, a vacuum degree of 0.1Mpa, and a time range of 18 hours to remove the sol...

Embodiment 2

[0050] Dissolve 1.5mM hydroxytyrosol in 50mL acetate buffer (0.1M, pH 5). In the enzymatic polymerization reaction, laccase solution (2.2 mg / mL, enzyme activity 660 U) was initially added. Place the flasks containing different reagents at 40°C with magnetic stirring for 3.5 hours, and then inactivate laccase at a high temperature of 90°C. During the enzymatic reaction, the color of the reaction medium gradually darkens and can be used to indicate the general progress of the polymerization reaction. After the polymerization reaction is completed, the reaction vessel is placed in a refrigerator at 0°C for 16 hours to precipitate the polymerization product. Then the precipitate was obtained by centrifugation at 4000r / min for 15min, and washed with a mixed solvent of acetone and chloroform (5:1, v / v) several times to remove unreacted hydroxytyrosol and laccase. The resulting polymer is placed in a temperature range of 50°C, a vacuum degree of 0.07Mpa, and a time range of 72 hours ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com