Method for preparing 13X molecular sieve through using high-alumina fly ash, and 13X molecular sieve

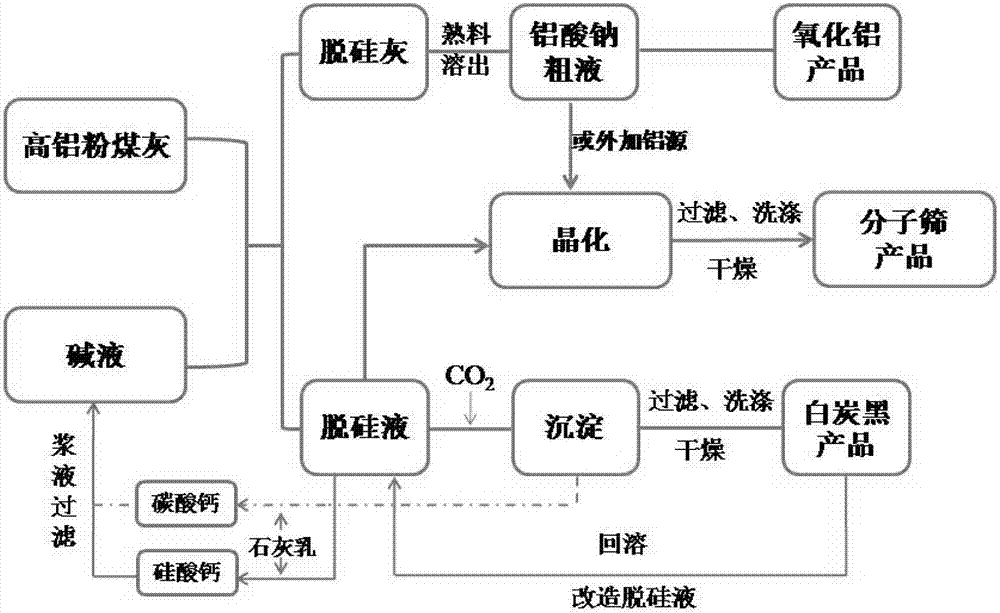

A high-alumina fly ash and molecular sieve technology, applied in the field of 13X molecular sieve, can solve the problems of low overall conversion rate of zeolite, low purity of molecular sieve, and low yield of single-pot, so as to promote green production, reduce raw material cost, and improve single-pot yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This example is used to illustrate the method for preparing 13X molecular sieve and 13X molecular sieve of the present invention.

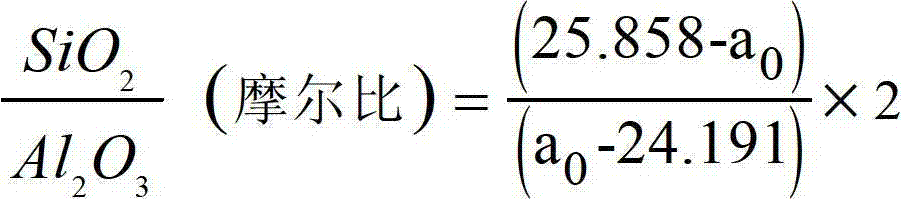

[0040] Weigh 1kg high aluminum fly ash (among them, Al 2 o 3 Accounting for 45wt%, SiO 2 accounted for 37wt%), after common impurity removal steps such as magnetic separation and screening, 2kg of 25wt% NaOH solution was added, and a pre-desilication reaction was carried out in a high-pressure reactor at 120°C for 4 hours, and the obtained material was filtered. Wash the filter residue until the pH value of the washing liquid is about 8, and combine the filtrate and washing liquid to obtain the desiliconization liquid. The composition of the desiliconization solution is shown in Table 1.

[0041] The composition of table 1 desiliconization solution

[0042] components

al 2 o 3

SiO 2

Na 2 o

CaO

Fe 2 o 3

CuO

Content (g / L)

2.04

50.4

117.2

0.015

0.0039

0...

Embodiment 2

[0049] This example is used to illustrate the method for preparing 13X molecular sieve and 13X molecular sieve of the present invention.

[0050] Weigh 1kg high aluminum fly ash (among them, Al 2 o 3 Accounting for 45wt%, SiO 2 accounted for 37wt%), after common impurity removal steps such as magnetic separation and screening, 3kg of 10wt% NaOH solution was added, and a pre-desilication reaction was carried out in a high-pressure reactor at 100°C for 8 hours, and the obtained material was filtered. Wash the filter residue until the pH value of the washing liquid is about 8, and combine the filtrate and washing liquid to obtain the desiliconization liquid.

[0051] Introduce CO into the desiliconization solution at 60°C 2 Stop aeration until the pH of the desiliconization solution reaches 8.5. SiO will be generated 2 The precipitate was filtered, washed, and then dried at 100°C to obtain white powdery silica. Due to SiO 2 The filtrate obtained during precipitation filtra...

Embodiment 3

[0054] This example is used to illustrate the method for preparing 13X molecular sieve and 13X molecular sieve of the present invention.

[0055] Weigh 1kg high aluminum fly ash (among them, Al 2 o 3 Accounting for 42wt%, SiO 2 accounted for 39wt%), after common impurity removal steps such as magnetic separation and screening, 2kg of 30wt% NaOH solution was added, and a pre-desilication reaction was carried out in a high-pressure reactor at 150°C for 1 hour, and the obtained material was filtered. Wash the filter residue until the pH value of the washing liquid is about 8, and combine the filtrate and washing liquid to obtain the desiliconization liquid.

[0056] Add limestone and sodium carbonate solution to the filter residue (also known as desilicate dust) to make raw slurry, roast the raw slurry to obtain clinker, then dissolve it with deionized water, and filter to obtain the filtrate Sodium aluminate crude solution.

[0057] Introduce CO into the desiliconization sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com