Method for recovering copper ions in acidic copper printed circuit board waste etching liquor and application

A technology for printed circuit boards and etching waste liquids, applied in chemical instruments and methods, circuits, cyanide reaction preparation, etc., can solve problems such as research reports on the application of negative electrode materials for lithium ion batteries that have not yet been seen, and promote a virtuous cycle. Electrochemical performance, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of recovery method of copper ion in acidic copper printed circuit board etching waste liquid, concrete steps are as follows:

[0025] (1) Dissolve sodium hydroxide and phenylalanine in distilled water, stir to obtain solution A, the concentration of sodium hydroxide in solution A is 33g / L, and the concentration of phenylalanine is 63g / L;

[0026] (2) Use a sodium hydroxide solution with a concentration of 0.05mol / L to adjust the pH value of the acidic copper printed circuit board etching waste solution to 0.2, and obtain solution B after stirring;

[0027] (3) According to the ratio of solution A:solution B volume ratio of 2:1, slowly add solution B dropwise to solution A to form a blue precipitate, wash with distilled water for 5 times, and then wash with alcohol for 8 times, Recover after drying to obtain blue copper phenylalanine crystal powder.

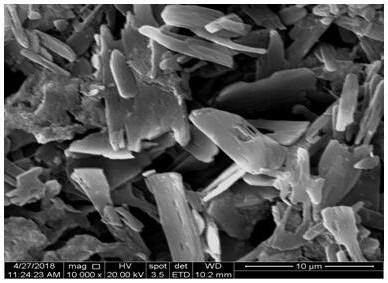

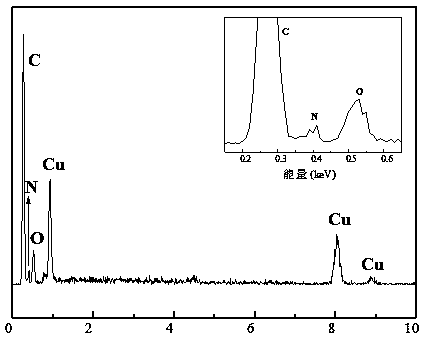

[0028] Adopt SEM to observe the microscopic appearance of the phenylalanine copper that this embodiment reclaims ...

Embodiment 2

[0031] A kind of recovery method of copper ion in acidic copper printed circuit board etching waste liquid, concrete steps are as follows:

[0032] (1) Dissolve sodium hydroxide and phenylalanine in distilled water, stir to obtain solution A, the concentration of sodium hydroxide in solution A is 16g / L, and the concentration of phenylalanine is 45g / L;

[0033] (2) Use a sodium hydroxide solution with a concentration of 2 mol / L to adjust the pH value of the acidic copper printed circuit board etching waste solution to 2, and obtain solution B after stirring;

[0034] (3) According to the ratio of solution A:solution B volume ratio of 6:1, slowly add solution B dropwise to solution A to form a blue precipitate, wash with distilled water for 6 times, and then wash with alcohol for 6 times, Recover after drying to obtain blue copper phenylalanine crystal powder.

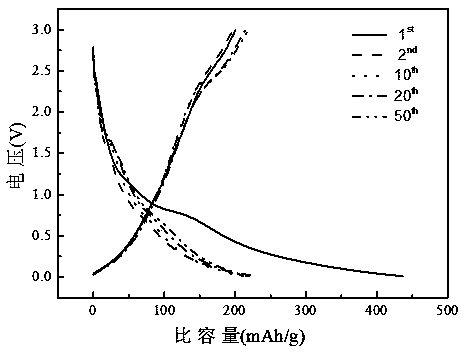

[0035] With the blue phenylalanine copper crystal powder recovered in this embodiment as the negative electrode activ...

Embodiment 3

[0037] A kind of recovery method of copper ion in acidic copper printed circuit board etching waste liquid, concrete steps are as follows:

[0038] (1) Dissolve sodium hydroxide and phenylalanine in distilled water, and stir to obtain solution A. The concentration of sodium hydroxide in solution A is 25g / L, and the concentration of phenylalanine is 16g / L;

[0039] (2) Use a sodium hydroxide solution with a concentration of 10mol / L to adjust the pH value of the acidic copper printed circuit board etching waste solution to 1, and obtain solution B after stirring;

[0040] (3) According to the ratio of solution A: solution B volume ratio of 1:1, slowly add solution B to solution A dropwise to form a blue precipitate, wash with distilled water for 7 times, and then wash with alcohol for 7 times. Recover after drying to obtain blue copper phenylalanine crystal powder.

[0041] With the blue phenylalanine copper crystal powder recovered in this embodiment as the negative electrode ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com